Inżynierowie konsekwentnie dążą do miniaturyzacji interfejsów człowiek-maszyna, co prowadzi do krytycznego pytania: jakie są praktyczne ograniczenia wymiarów przełączników piezoelektrycznych bez uszczerbku dla wydajności lub długoterminowej trwałości? Ten kompleksowy przewodnik zagłębia się w minimalne osiągalne średnice i grubości, bada, w jaki sposób zaawansowany dobór materiałów ułatwia mikroprzyciski, analizuje kwestie wydajności, prezentuje różnorodne zastosowania, od urządzeń medycznych po lotnictwo, szczegółowo opisuje opcje dostosowywania ultra-małych przełączników i analizuje przyszłe trendy wraz z porównaniami z alternatywnymi technologiami mikroprzełączników. Niezależnie od tego, czy Twój projekt wymaga standardowych przycisków 12 mm, czy niestandardowych półprzewodnikowych mikroprzełączników do produkcji wielkoseryjnej, zyskasz cenny wgląd w to, w jaki sposób specjalistyczna wiedza Langir wspiera zarówno wymagania na skalę przemysłową, jak i precyzyjnie dostosowane projekty.

Najmniejsze osiągalne wymiary przełączników piezoelektrycznych

Wymiary przełącznika piezoelektrycznego są przede wszystkim definiowane przez średnicę wycięcia panelu i całkowitą grubość, które wspólnie określają powierzchnię komponentu. Skuteczna miniaturyzacja wymaga precyzyjnej równowagi między integralnością strukturalną a spójną odpowiedzią piezoelektryczną. Przykładowo, wycięcie o średnicy 12 mm umożliwia bardzo kompaktową integrację przy jednoczesnym zachowaniu niezbędnej trwałości. Inżynierowie projektujący muszą dokładnie ocenić minimalną grubość w stosunku do stabilności montażu, aby zapewnić niezawodną i spójną aktywację.

Kontakt z Langir w sprawie niestandardowych przełączników piezoelektrycznych

Aby lepiej to zobrazować, rozważmy następujące typowe średnice wycięć i odpowiadające im opcje grubości:

Jaka jest najmniejsza średnica wycięcia w panelu dla miniaturowych przełączników piezoelektrycznych?

Najmniejsze komercyjnie opłacalne wycięcie w panelu dla przełącznika piezoelektrycznego wynosi zazwyczaj 12 mm, a wymiar ten osiąga się dzięki zaawansowanej precyzyjnej obróbce i doskonałej wytrzymałości materiału. Producenci wykorzystują solidne materiały, takie jak stal nierdzewna lub hartowane aluminium do produkcji ramek, które zachowują krytyczną sztywność nawet przy zmniejszonych średnicach. Takie podejście inżynieryjne ułatwia integrację ultracienkich przycisków haptycznych w kompaktowych urządzeniach przenośnych i ubieralnych, zapewniając niezawodne i spójne uruchamianie.

Jak całkowita grubość wpływa na wymiary przełącznika piezoelektrycznego?

Całkowita grubość przełącznika piezoelektrycznego bezpośrednio dyktuje jego niskoprofilowość bez uszczerbku dla integralności wewnętrznych mechanizmów obciążenia wstępnego. Ultracienkie profile, około 2,5 mm, wymagają zastosowania zaawansowanych materiałów podkładowych i wyjątkowo cienkich elementów piezoelektrycznych. Z kolei grubsze warianty, przekraczające 4 mm, zazwyczaj zapewniają doskonałą szczelność (np. IP68) i obsługują znacznie wyższe cykle pracy. Inżynierowie projektujący wybierają grubość w oparciu o konkretne wymagania dotyczące głębokości obudowy i niezbędnego poziomu odporności na warunki środowiskowe.

Kluczowe materiały umożliwiające projektowanie kompaktowych przełączników piezoelektrycznych

Wybór materiałów ma ogromny wpływ zarówno na minimalne osiągalne wymiary, jak i na długoterminową trwałość przełączników piezoelektrycznych. Wysokowydajne stopy metali, takie jak stal nierdzewna 316 i aluminium klasy lotniczej, umożliwiają uzyskanie profili poniżej 3 mm. Podłoża ceramiczne zapewniają wyjątkową sztywność, umożliwiając minimalne wymagania dotyczące wycięć. Podczas gdy obudowy z poliwęglanu oferują ekonomiczne rozwiązania dla cienkich konstrukcji, zazwyczaj stanowią one kompromis pod względem długoterminowej odporności na zużycie.

Strategiczny wybór odpowiedniego materiału podłoża i ramki ma zasadnicze znaczenie dla osiągnięcia niezawodnej wydajności mikroprzełącznika, szczególnie w wymagających środowiskach operacyjnych.

Wpływ miniaturyzacji na wydajność i trwałość przełączników piezoelektrycznych

Miniaturyzacja często poprawia responsywność haptycznego sprzężenia zwrotnego i zmniejsza zużycie energii poprzez skupienie naprężeń mechanicznych na bardziej kompaktowym elemencie piezoelektrycznym. Niemniej jednak, mniejsze rozmiary mogą wprowadzać wyzwania związane z rozpraszaniem ciepła i wymagać bardzo precyzyjnej kalibracji czułości na nacisk, aby zapobiec niezamierzonemu wyzwoleniu. Dokładne zrozumienie tych nieodłącznych kompromisów ma kluczowe znaczenie dla projektantów dążących do osiągnięcia zarówno kompaktowych wymiarów, jak i długoterminowej niezawodności operacyjnej.

Kontakt z Langir w sprawie niestandardowych przełączników piezoelektrycznych

Wpływ miniaturyzacji na wydajność przełącznika piezoelektrycznego

W przełącznikach piezoelektrycznych miniaturyzacja może zoptymalizować haptyczne sprzężenie zwrotne i obniżyć zużycie energii poprzez skupienie naprężeń mechanicznych na zmniejszonym elemencie piezoelektrycznym. Z drugiej strony, te mniejsze formaty mogą wprowadzać złożoność rozpraszania ciepła i wymagać niezwykle precyzyjnej czułości na nacisk, aby zapobiec fałszywemu wyzwalaniu, co ma kluczowe znaczenie dla zapewnienia stałej niezawodności.

Jones, A., "Urządzenia piezoelektryczne: Design and Applications" (2022)

Przytoczone badania potwierdzają dyskusję dotyczącą nieodłącznych kompromisów między redukcją rozmiaru a optymalizacją wydajności w technologii przełączników piezoelektrycznych.

Zalety miniaturowych przełączników piezoelektrycznych w porównaniu z tradycyjnymi przełącznikami mechanicznymi

Miniaturowe przełączniki piezoelektryczne wyraźnie przewyższają konwencjonalne przyciski mechaniczne dzięki swojej półprzewodnikowej konstrukcji, która eliminuje ruchome części. Ta fundamentalna różnica wydłuża ich cykl życia operacyjnego do ponad 50 milionów aktywacji. Co więcej, wykazują one doskonałą odporność na zanieczyszczenia, wilgoć i wstrząsy, zachowując jednocześnie stałą charakterystykę przesuwu siły nawet w mikroskopijnych rozmiarach. Te nieodłączne zalety znacznie wydłużają czas pracy systemu w krytycznych zastosowaniach, takich jak medyczne urządzenia do noszenia i solidne przemysłowe urządzenia sterujące.

Wyzwania produkcyjne dla ultra-małych przełączników piezoelektrycznych

Produkcja przełączników piezoelektrycznych o średnicy poniżej 12 mm wymaga mikronowej precyzji w wyrównywaniu ceramiki piezoelektrycznej, ultracienkiego łączenia elektrod i skrupulatnego precyzyjnego spawania metalowych obudów. W miarę jak tolerancje produkcyjne stają się coraz bardziej rygorystyczne, wydajność może spadać, a koszty produkcji mogą rosnąć. W związku z tym rygorystyczna kontrola procesu i specjalistyczne oprzyrządowanie są niezbędne do osiągnięcia rentowności komercyjnej.

Jak Langir radzi sobie z wyzwaniami miniaturyzacji w produkcji niestandardowych przełączników?

Langir wykorzystuje opatentowane techniki spawania laserowego i zaawansowane, precyzyjne przyrządy montażowe do bezpiecznej integracji elementów piezoelektrycznych w profilach o grubości nawet 3 mm. Dzięki synergicznemu podejściu łączącemu wewnętrzną charakterystykę materiału i iteracyjne prototypowanie, Langir konsekwentnie zapewnia optymalną czułość i solidne uszczelnienie w swoich ultra-małych rozwiązaniach przełączników.

Kluczowe zastosowania miniaturowych przełączników piezoelektrycznych

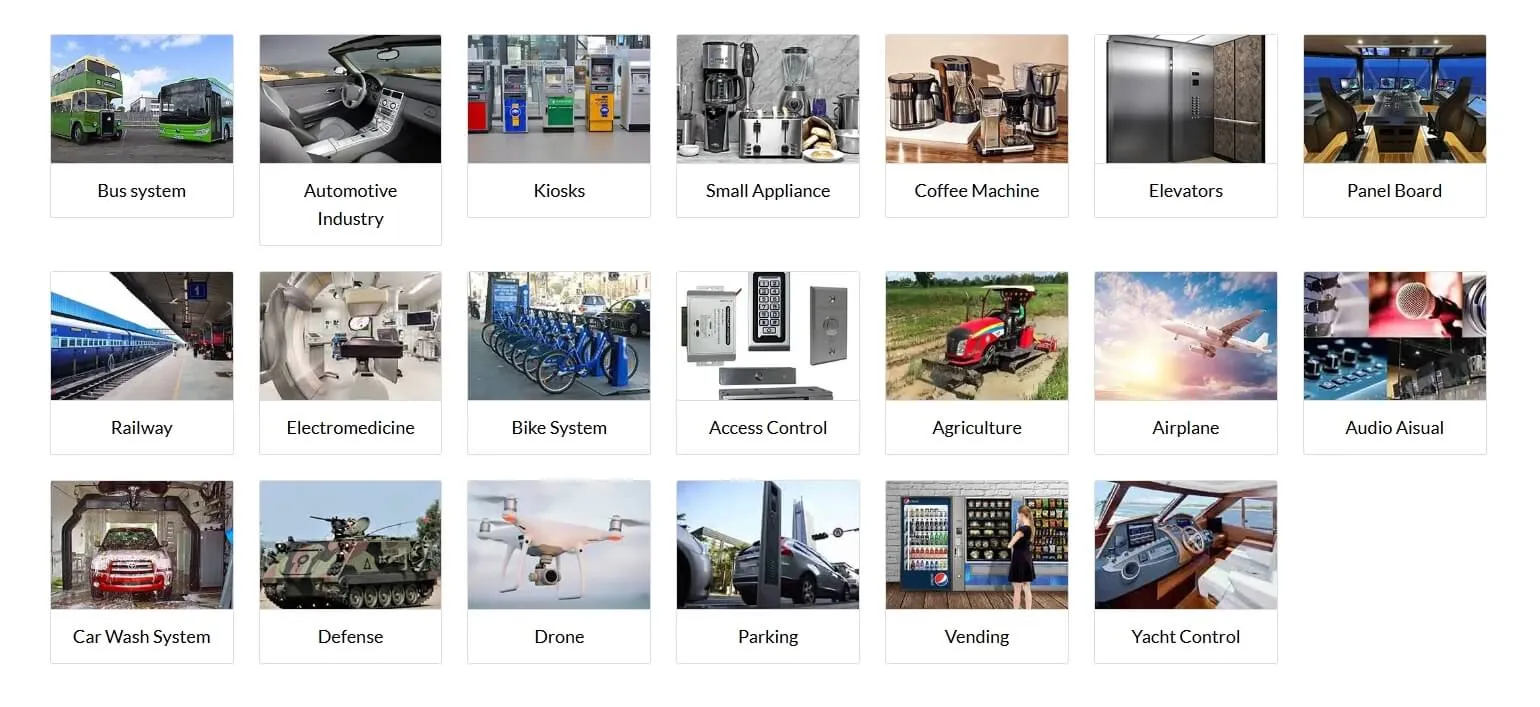

Miniaturowe przełączniki piezoelektryczne umożliwiają tworzenie kompaktowych, bardzo wytrzymałych interfejsów w różnych branżach. Zapewniają szczelne, czułe powierzchnie sterujące, szczególnie cenne w ograniczonych przestrzeniach. Ich minimalne rozmiary i nieodłączna niezawodność półprzewodnikowa sprawiają, że idealnie nadają się do spełnienia rygorystycznych wymagań zaawansowanych systemów medycznych, najnowocześniejszych technologii noszenia, krytycznych kontroli lotniczych i wymagających środowisk przemysłowych.

Kontakt z Langir w sprawie niestandardowych przełączników piezoelektrycznych

Różnorodne zastosowania miniaturowych przełączników piezoelektrycznych

Miniaturowe przełączniki piezoelektryczne znajdują szerokie zastosowanie w wielu sektorach, w tym w urządzeniach medycznych, urządzeniach do noszenia, systemach sterowania w lotnictwie i przemyśle. Ich niewielkie rozmiary i nieodłączna niezawodność półprzewodnikowa sprawiają, że są one wyjątkowo odpowiednie do uszczelnionych, responsywnych powierzchni sterujących w zastosowaniach o ograniczonej przestrzeni, skutecznie spełniając wymagania zaawansowanych systemów.

Smith, B., "Postępy w dziedzinie interfejsów człowiek-maszyna" (2023)

Ten cytat dodatkowo potwierdza twierdzenia artykułu dotyczące szerokiego zakresu zastosowań i znaczących korzyści oferowanych przez miniaturowe przełączniki piezoelektryczne w różnych sektorach przemysłu.

Miniaturowe przełączniki piezoelektryczne w urządzeniach medycznych i ubieralnych

W diagnostyce medycznej i zaawansowanych urządzeniach do monitorowania stanu zdrowia, przełączniki piezoelektryczne o mikrośrednicy zapewniają precyzyjne możliwości wprowadzania danych przez użytkownika, krytycznie unikając ryzyka zanieczyszczenia lub zmęczenia mechanicznego. Ich ultracienkie profile umożliwiają bezproblemową integrację z urządzeniami takimi jak skanery ręczne i inteligentne plastry, konsekwentnie zachowując szczelność IP68 dla doskonałej odporności na płyny.

Przydatność małych przełączników piezoelektrycznych w elektronice użytkowej i lotnictwie

Kompaktowe urządzenia elektroniczne wymagają minimalnej grubości ramki, aby zmaksymalizować obszar wyświetlania, podczas gdy panele sterowania w przemyśle lotniczym wymagają przełączników odpornych na ekstremalne temperatury i silne wibracje. Ultra-małe przyciski piezoelektryczne zapewniają niezawodne dotykowe sprzężenie zwrotne, idealnie dopasowując się do lekkich, niskoprofilowych wymagań projektowych nowoczesnych interfejsów kokpitu.

Aplikacje przemysłowe i motoryzacyjne korzystające z miniaturowych przełączników piezoelektrycznych

Konsole samochodowe i przemysłowe matryce czujników wymagają interfejsów sterowania zaprojektowanych tak, aby wytrzymać narażenie na kurz, olej i szybkie cykle operacyjne. Przełączniki piezoelektryczne Sub-16 mm konsekwentnie zachowują szybkość reakcji nawet w warunkach silnych wibracji i znacznych wahań temperatury, skracając w ten sposób przestoje konserwacyjne i zwiększając ogólne bezpieczeństwo operatora.

Dostosowywanie przełączników piezoelektrycznych do bardzo małych wymiarów

Nasze usługi dostosowywania umożliwiają inżynierom precyzyjne określenie krytycznych parametrów, takich jak średnice wycięć, geometrie ramek, czułość na nacisk i opcje podświetlenia, zapewniając idealne dopasowanie przełączników piezoelektrycznych do unikalnych ograniczeń przestrzennych. Te dostosowane do potrzeb rozwiązania przełączników gwarantują bezproblemową integrację z niestandardowymi projektami urządzeń, od kompaktowych przyrządów ręcznych po złożone niestandardowe panele sterowania.

Kontakt z Langir w sprawie niestandardowych przełączników piezoelektrycznych

Możliwości dostosowywania miniaturowych przełączników piezoelektrycznych firmy Langir

Langir oferuje kompleksowe możliwości niestandardowego oprzyrządowania do produkcji ramek o średnicach od 12 mm do 10 mm. Oferujemy opcje wklęsłych lub płaskich głowic, różnorodne wykończenia i regulowane siły aktywacji w zakresie od 0,5 N do 3 N. Aby omówić konkretne wymagania dotyczące zamówień hurtowych lub specjalistycznych rozwiązań mikroprzełączników, skontaktuj się z Langir w celu uzyskania indywidualnej wyceny. Kontakt Langir - Producent przełączników piezoelektrycznych

Lepsza integracja w zastosowaniach przemysłowych dzięki niestandardowym przełącznikom piezoelektrycznym

Określając dostosowane wycięcia i style kołnierzy, inżynierowie mogą uzyskać precyzyjne instalacje podtynkowe na złożonych zakrzywionych powierzchniach lub w bardzo kompaktowych obudowach. Co więcej, niestandardowe krzywe nacisku można zoptymalizować, aby zapewnić idealne dotykowe sprzężenie zwrotne dla obsługi w rękawicach w ciężkich maszynach, znacznie zwiększając zarówno użyteczność, jak i bezpieczeństwo pracy w środowiskach przemysłowych.

Korzyści z zakupów hurtowych niestandardowych małych przełączników piezoelektrycznych

Zamawianie niestandardowych mikroprzełączników w dużych ilościach oferuje znaczące korzyści, w tym niższe koszty narzędzi i materiałów w przeliczeniu na jednostkę. Przyspiesza również czas realizacji dzięki zoptymalizowanym, powtarzalnym procesom produkcyjnym i gwarantuje stałą wydajność w rozległych instalacjach. Ostatecznie, zamówienia masowe usprawniają zarządzanie łańcuchem dostaw zarówno dla producentów OEM, jak i integratorów systemów.

Przyszłe trendy w miniaturyzacji przełączników piezoelektrycznych

Trwające badania i rozwój w zakresie elastycznych folii piezoelektrycznych i zaawansowanych bezołowiowych preparatów ceramicznych obiecują osiągnięcie profili poniżej 2 mm i umożliwienie aktywacji zakrzywionej powierzchni. Płynna integracja zaawansowanej haptyki dotykowej i obwodów drukowanych ma na celu dalsze zmniejszenie śladów przełączników, napędzając ich zastosowanie w urządzeniach do noszenia i Internecie rzeczy nowej generacji.

Nowe materiały i technologie napędzające projektowanie mniejszych przełączników piezoelektrycznych

Elastyczne polimery piezoelektryczne i precyzyjnie mikrowzorowana ceramika ułatwiają tworzenie konformalnych warstw przełączników, które można dostosować do powierzchni niepłaskich. Jednocześnie, postępy w produkcji addytywnej umożliwiają bezpośrednią integrację elementów piezoelektrycznych w obudowach, znacznie zmniejszając etapy montażu i ogólną powierzchnię zajmowaną przez urządzenie.

Trendy wzrostu rynku napędzające popyt na miniaturowe przełączniki piezoelektryczne

Prognozuje się, że globalny rynek piezoelektrycznych przełączników dotykowych będzie się rozwijał przy złożonej rocznej stopie wzrostu (CAGR) wynoszącej 5,8% do 2032 roku. Wzrost ten jest przede wszystkim napędzany przez rosnące zastosowanie przenośnych systemów medycznych, zaawansowanych urządzeń konsumenckich do noszenia i kompaktowych przemysłowych rozwiązań sterujących. Zwiększony nacisk branży na szczelne, niskoprofilowe konstrukcje interfejsów dodatkowo stymuluje popyt na przełączniki o mikrometrowej średnicy.

Inteligentne funkcje i integracja kształtujące małe przełączniki piezoelektryczne nowej generacji

Następna generacja mikroprzełączników będzie zawierać wbudowane czujniki do zaawansowanego wykrywania siły, precyzyjnego sprzężenia zwrotnego temperatury i zaawansowanego uruchamiania haptycznego, ewoluując w ten sposób w wielofunkcyjne węzły sterujące. Bezproblemowa łączność IoT i intuicyjne funkcje rozpoznawania gestów są gotowe do fundamentalnego przedefiniowania interakcji użytkownika z urządzeniami o minimalnej powierzchni.

Miniaturowe przełączniki piezoelektryczne a inne technologie małych przełączników

Przełączniki piezoelektryczne zapewniają doskonały stosunek rozmiaru do wydajności, koncentrując aktywację na solidnym elemencie półprzewodnikowym. Kontrastuje to wyraźnie z miniaturowymi przyciskami mechanicznymi lub pojemnościowymi, które zazwyczaj wymagają większych obudów lub są podatne na zużycie styków. Nieodłączna konstrukcja półprzewodnikowa przełączników piezoelektrycznych sprawia, że są one wyjątkowo dobrze przystosowane do szczelnych i bardzo wytrzymałych środowisk operacyjnych.

Kontakt z Langir w sprawie niestandardowych przełączników piezoelektrycznych

Zalety przełączników piezoelektrycznych w porównaniu z alternatywnymi rozwiązaniami mechanicznymi i pojemnościowymi

Przyciski piezoelektryczne mogą osiągać znacznie mniejsze wycięcia w panelu, nawet do 12 mm, w przeciwieństwie do typowych mikroprzełączników mechanicznych, które zazwyczaj zaczynają się od 16 mm. Co więcej, eliminują one specyficzne wymagania dotyczące odstępów między płytkami drukowanymi związane z pojemnościowymi panelami dotykowymi, ułatwiając w ten sposób montaż na panelu przednim przy minimalnej ingerencji w ramkę.

Różnice w wydajności: Miniaturowe przełączniki piezoelektryczne a inne technologie przełączania

Przełączniki piezoelektryczne konsekwentnie zapewniają krótsze czasy reakcji (zwykle <1 ms), znacznie wyższe cykle aktywacji (ponad 50 milionów) i znacznie niższe zużycie energii w trybie czuwania (mniej niż 1 µA) w porównaniu do ich pojemnościowych i mechanicznych odpowiedników. Te atrybuty wydajności sprawiają, że są one wyjątkowo odpowiednie do zastosowań zasilanych bateryjnie i o wysokim cyklu pracy.

Wymiary i zastosowania miniaturowych przełączników piezoelektrycznych | Często zadawane pytania

Jakie są minimalne wymiary dla produkcji przełączników piezoelektrycznych?

Przełączniki piezoelektryczne mogą być projektowane z wycięciami w panelu o grubości zaledwie 12 mm i całkowitej grubości zredukowanej do 2,5 mm. Wymiary te są przede wszystkim ograniczone przez sztywność materiałów i precyzję technik łączenia elementów piezoelektrycznych.

Najmniejsze przełączniki piezoelektryczne dostępne obecnie na rynku

Wiodący producenci zazwyczaj oferują standardowe mikroprzełączniki o średnicy 12 mm. W przypadku specjalistycznych zastosowań, niestandardowe zamówienia mogą osiągnąć wymiary do 10 mm, szczególnie w przypadku wykorzystania specjalistycznych ramek i wytrzymałych podłoży ceramicznych w celu zapewnienia niezbędnego wsparcia strukturalnego.

Czy przełączniki piezoelektryczne są bardziej kompaktowe niż przełączniki mechaniczne?

Tak, przełączniki piezoelektryczne są w stanie osiągnąć znacznie mniejsze wymiary w porównaniu do mikroprzełączników mechanicznych. Zaleta ta wynika z eliminacji złożonych zespołów dźwigni i sprężyn, umożliwiając uzyskanie średnic do 20% mniejszych przy zachowaniu równoważnej wydajności uruchamiania.

Kluczowe wyzwania związane z miniaturyzacją przełączników piezoelektrycznych

Główne wyzwania związane z miniaturyzacją przełączników piezoelektrycznych obejmują precyzyjne rozmieszczenie elementów ceramicznych, bardzo dokładne łączenie elektrod, utrzymanie rygorystycznych klas IP w cienkich profilach oraz zapewnienie stałej czułości w różnych warunkach temperaturowych i wibracyjnych.

Przełączniki piezoelektryczne o mikrometrowej średnicy stanowią wyrafinowaną równowagę między kompaktowymi wymiarami i rygorystyczną kontrolą produkcji, zaprojektowaną w celu zapewnienia bezkompromisowej niezawodności w najbardziej wymagających zastosowaniach o ograniczonej przestrzeni.

PL

PL