Capacitive contact sensing is the engine behind today’s slick touch interfaces, working by sensing shifts in an electric field. But can this tech stand up to the tough demands of industrial automation? Dive into this guide to uncover how capacitive contact sensing operates, why capacitive switches are revolutionizing factory HMIs, where they truly shine in robotics and fluid monitoring, and how you can tailor them for your specific production line. We’ll also walk you through Langir’s bulk-order and customization services, highlight key market trends, and tackle the questions engineers are asking most. By the end, you’ll have a clear picture of how capacitive switch technology can boost durability, reliability, and the user experience on your factory floor.

What Exactly Is Capacitive Contact Sensing and How Does It Work?

Capacitive contact sensing is a cutting-edge, non-contact technology. It detects changes in capacitance when a conductive or dielectric object disrupts an electric field, allowing for precise touch and proximity detection without any moving parts. This design significantly reduces mechanical wear and tear and resists contamination, making it a perfect fit for challenging environments. For instance, when a fingertip gets close to an embedded electrode, it alters the local capacitance, triggering a switch event within a sealed control panel.

Get a quote for custom capacitive switches from Langir

What Is Capacitive Sensing Technology?

Capacitive sensing technology establishes an electric field between electrodes and measures shifts in capacitance as an object enters this field. It operates on the principle that capacitance () increases when a dielectric material, like a finger or liquid, comes into proximity. In practice, even a minor fluctuation in capacitance generates a detectable voltage change that microcontrollers interpret as a touch or proximity event, providing a dependable, wear-free interface for industrial controls.

Typically, capacitive sensing systems comprise:

- An electrode layer, precisely patterned and printed on a PCB or overlay

- A protective dielectric barrier (made from glass, plastic, or a coated panel)

- A sophisticated sensing IC that converts capacitance variations into digital signals

These components work in harmony to detect contact or proximity. This same architecture supports everything from simple push-button actions to complex multi-touch gestures, setting the stage for how capacitive switches stack up against traditional mechanical buttons.

How Do Capacitive Switches Perform Compared to Mechanical Buttons?

While capacitive switches and mechanical buttons achieve similar end results—signaling on/off states—their underlying mechanisms are fundamentally different:

Capacitive switches bypass issues of friction and corrosion, whereas mechanical buttons offer a pronounced, satisfying click. These distinctions guide designers toward touch-based panels that prioritize enduring performance and wash-down capabilities over tactile feedback.

What Are the Core Components: Capacitance, Electrodes, and Dielectrics?

A capacitive contact sensor relies on three fundamental elements:

- Capacitance: This is the ability to store an electric charge, and it changes based on how close an object is.

- Electrodes: These are conductive surfaces or traces that generate and detect the electric field.

- Dielectrics: These are insulating layers (like glass, acrylic, or polycarbonate) that shield the electrodes and determine the sensor’s sensitivity.

Together, these parts form a capacitive cell. The electrodes carry an alternating current, the dielectric establishes a stable baseline, and any change in capacitance triggers the sensing logic. Understanding these components is key to grasping the differences between self-capacitance and mutual-capacitance designs.

What Are the Types of Capacitive Sensing: Self-Capacitance vs. Mutual Capacitance?

Capacitive sensing is broadly categorized into two main configurations:

Self-capacitance setups are ideal for straightforward button arrays where only one sensor is active at a time. Mutual-capacitance grids, on the other hand, are designed to detect multiple touch points simultaneously. Recognizing these methods helps explain why capacitive switches are so advantageous in automation.

Why Are Capacitive Switches a Smart Choice for Industrial Automation

Capacitive switches deliver exceptional performance on factory floors by combining non-contact sensing with superior environmental resistance, leading to extended lifespans and significantly reduced maintenance. Their robust, sealed designs effectively repel dust, water, and chemicals, minimizing costly downtime and service calls. Next, we’ll explore how these switches achieve such remarkable durability in demanding settings.

Get a quote for custom capacitive switches from Langir

Capacitive Switches in Industrial Settings

Capacitive switches are exceptionally well-suited for industrial automation thanks to their inherent durability and resistance to environmental factors like dust and moisture, resulting in longer operational lifespans and lower maintenance requirements.

How Do Capacitive Switches Ensure Durability and Longevity in Tough Environments?

Capacitive switches feature no mechanical wear surfaces, enabling them to endure millions of actuations even when subjected to moisture, dust, and rigorous cleaning agents. A sealed overlay, typically made of glass or polycarbonate, provides IP67 protection, preventing the ingress that would incapacitate the moving parts found in conventional buttons. This resilience translates directly into fewer replacements and uninterrupted production cycles, whether in automotive stamping lines or food-grade processing facilities.

This exceptional environmental toughness paves the way for the significant design flexibility these switches offer for human-machine interfaces.

What Design Flexibility Do Capacitive Switches Bring to Industrial HMIs?

Capacitive switch overlays can be expertly crafted from materials like glass, acrylic, stainless steel, or even stone, allowing for sleek, seamless panels that perfectly complement any aesthetic or branding. Colors, integrated backlighting, and custom icons can be embedded directly beneath the cover layer, resulting in intuitive layouts with no exposed seams. This adaptability means control panels can be precisely tailored to operator workflows and stringent safety standards, all while maintaining essential wash-down or chemical-resistance capabilities.

This remarkable versatility directly enhances the operator experience through refined touch sensitivity and feedback mechanisms.

How Do Capacitive Switches Elevate User Experience with Touch and Feedback?

Capacitive interfaces require only a minimal touch force—typically between 10–50 grams—significantly reducing operator fatigue during repetitive tasks. Integrated haptic motors or audible buzzers can effectively simulate the satisfying click of mechanical buttons, while uniform backlighting ensures excellent visibility even in dimly lit environments. These features combine to create intuitive, ergonomic control surfaces that accelerate operator training and minimize input errors.

Enhanced touch and feedback capabilities also enable the detection of non-metallic objects, expanding sensing possibilities beyond simple finger contact.

Can Capacitive Sensors Detect Non-Metallic Objects in Industrial Settings?

Absolutely. Capacitive sensors are highly sensitive to any material possessing a dielectric constant greater than that of air. This includes common materials like plastics, paper, wood, and various liquids. This capability allows for precise level sensing within opaque tanks or reliable detection of jams on conveyor systems when non-metallic debris accumulates. By carefully tuning the electrode geometry and drive frequency, engineers can effectively differentiate between conductive and dielectric objects, ensuring dependable detection even in complex production environments.

Understanding these versatile benefits makes it clear why capacitive contact sensing is a preferred technology across a wide spectrum of industrial applications.

What Are the Key Industrial Applications for Capacitive Contact Sensing

Capacitive contact sensing truly excels in applications demanding sealed, highly reliable switches and precise proximity or level detection. From sophisticated robotics control panels to intricate fluid monitoring systems, its wear-free operation and broad material sensitivity are driving innovation on the factory floor. Let’s explore three prominent high-volume use cases.

Get a quote for custom capacitive switches from Langir

Applications of Capacitive Sensors

Capacitive sensors are integral to industrial automation for object detection, level sensing, and proximity detection, significantly enhancing workflow efficiency and precision across diverse applications.

How Are Capacitive Push Button Switches Utilized in Robotics and Control Panels?

Within robotic workcells, capacitive push buttons serve critical functions as emergency stop and mode-select switches, often mounted discreetly behind protective safety curtains. Their sealed overlays effectively prevent coolant ingress and resist welding spatter, ensuring reliable operation even when continuously exposed to oils and lubricants. The low-force actuation also prevents accidental triggering while operators are adjusting tooling.

This application powerfully demonstrates the seamless integration of capacitive switches into the complex architecture of modern machinery cabinets.

Can Capacitive Sensors Reliably Monitor Fluid Levels and Detect Objects?

Indeed. By positioning electrodes externally to a tank wall, capacitive sensors can accurately measure the dielectric change as liquid levels rise or fall, enabling continuous, non-contact monitoring. Similarly, on conveyor systems, these sensors can detect jams by sensing the capacitance increase when material accumulates against a designated target area. These implementations drastically reduce the maintenance required for mechanical float systems and significantly boost uptime in demanding sectors like chemical processing and packaging lines.

The ability to monitor fluid levels and object presence also brings substantial benefits to industries such as food processing and wastewater treatment.

How Is Capacitive Sensing Applied in Medical and Consumer Electronics with Industrial Relevance?

In the medical field, capacitive keys are employed for sterilizable control surfaces in operating rooms, ensuring hygiene and ease of cleaning. Similarly, consumer-grade equipment like vending machines leverage touch panels for their robust ingress protection. These successful cross-industry applications highlight that capacitive contact sensing meets rigorous hygiene and reliability standards, underscoring its suitability for industrial HMIs that undergo frequent cleaning and sanitization protocols.

Such proven performance across diverse sectors builds strong confidence for adoption in even the most demanding heavy-duty manufacturing environments.

How Can Capacitive Switches Be Tailored for Specific Industrial Requirements

Custom capacitive switches are engineered to meet unique industrial demands by carefully selecting overlay materials, precisely tuning sensitivity, and implementing robust interference mitigation strategies. From exotic finishes to EMC-hardened PCBs, these tailored designs guarantee optimal performance in virtually any production scenario. Let’s now delve into material choices and overlay options.

Get a quote for custom capacitive switches from Langir

What Materials and Overlay Options Are Available for Custom Capacitive Switches?

Industrial capacitive overlays can be fabricated from a variety of high-performance materials:

- Tempered Glass: Offers exceptional durability, superior scratch resistance, and a premium aesthetic.

- Acrylic: A lightweight, cost-effective option that is easy to engrave with custom designs.

- Stainless Steel: Provides excellent chemical resistance and a rugged, industrial appearance.

- Wood or Stone Veneers: Ideal for unique design accents on specialty equipment.

Each material choice influences sensitivity, cleaning procedures, and the tactile feel of the interface, enabling the creation of a precisely engineered solution that aligns with both aesthetic preferences and critical performance criteria.

How Are Parasitic Capacitance and Noise Immunity Handled in Custom Designs?

Engineers effectively minimize parasitic capacitance by incorporating ground planes, guard traces, and strategic shielding around signal lines. Furthermore, drive frequencies can be precisely tuned to avoid electromagnetic interference (EMI) generated by sources like motors or welding equipment. Advanced techniques such as differential sensing and sophisticated firmware filtering algorithms further reject spurious signals, ensuring that only intentional touches are registered. These comprehensive strategies guarantee consistent and reliable switch activation, even in electrically noisy factory environments.

Effectively managing interference readies the design for seamless pilot runs and full-scale production deployment.

What Is the Process from Concept to Bulk Production for Custom Capacitive Switches?

Our customization process follows a structured, three-phase workflow:

- Concept & Specification – Clearly define the desired form factor, overlay material, iconography, and all electrical requirements.

- Prototype & Validation – Develop sample units for rigorous environmental testing, EMC certification, and ergonomic evaluations.

- Production & Delivery – Establish efficient SMT and assembly lines, implement stringent quality control checks, and scale up to volume manufacturing.

This methodical approach ensures the timely delivery of dependable capacitive switch solutions that integrate flawlessly into your equipment.

How Does Langir Deliver Advanced Capacitive Contact Sensing Solutions for Industry

Langir specializes in industrial capacitive push button switches, offering comprehensive end-to-end customization and efficient bulk ordering services. Leveraging in-house design engineering expertise and robust global supply chain management, Langir provides sealed, reliable controls precisely tailored to your exact specifications. Let’s explore our extensive offerings and dedicated services.

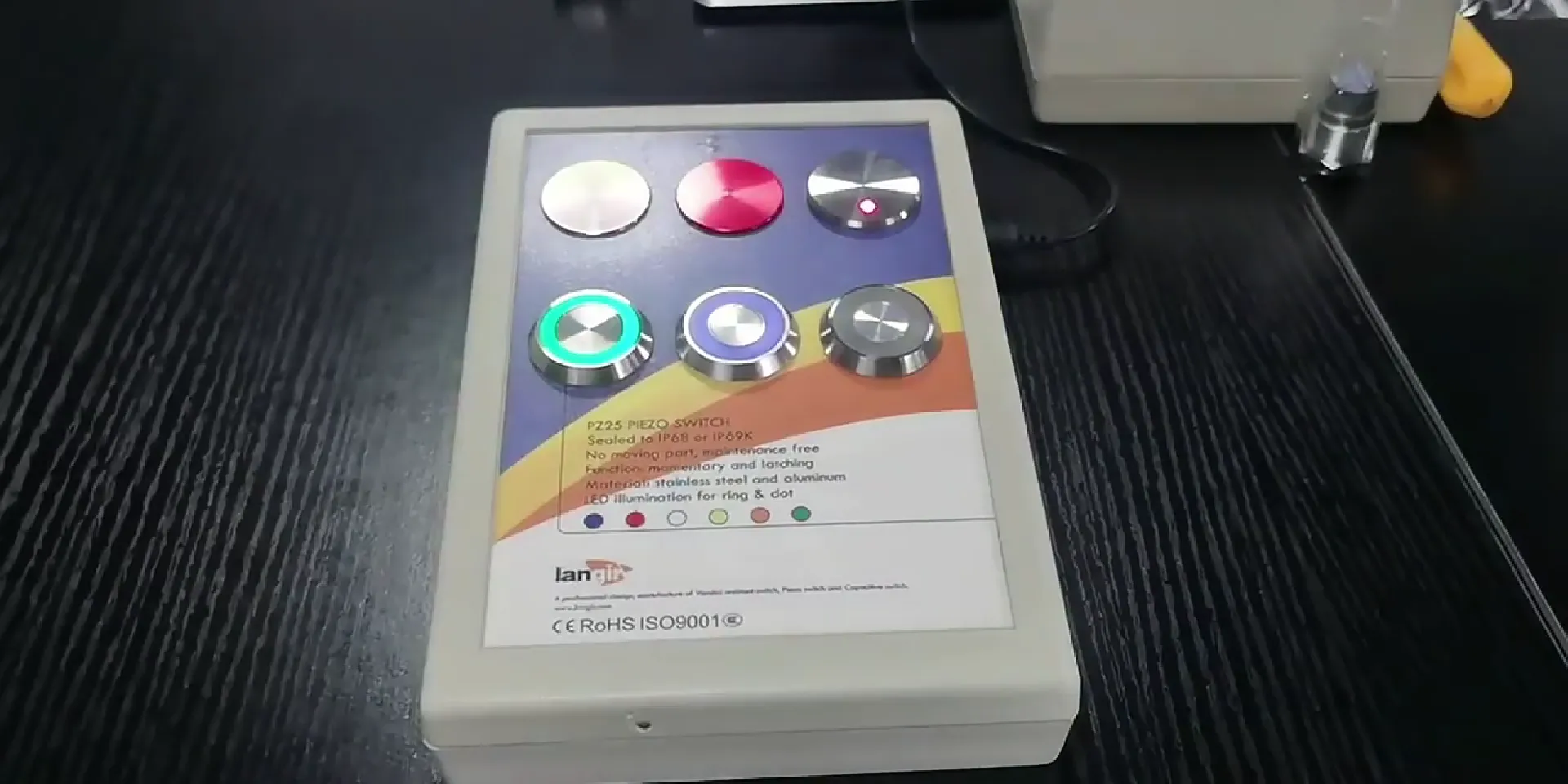

What Industrial Capacitive Push Button Switches Does Langir Provide?

Langir’s diverse product portfolio includes:

- Standard single-zone capacitive buttons (fully IP67-rated)

- Multi-zone capacitive keypads with fully customizable layouts

- Highly durable, percussion-resistant stainless-steel models for demanding applications

- Hygienic glass-surface switches specifically designed for food and pharmaceutical sectors

Langir Capacitive Switches

Langir offers a comprehensive selection of capacitive switches engineered for industrial applications, emphasizing exceptional durability, minimal activation force, and superior resistance to environmental factors, making them ideal for repetitive use and challenging conditions.

How Can Clients Leverage Langir’s Bulk Ordering and Customization Services?

By partnering with Langir, industrial manufacturers gain access to advantageous volume pricing and expert design support. You can easily request sample prototypes, iterate on overlay artwork, and secure reliable lead times for large orders, all managed seamlessly under one roof. To discuss your specific project requirements or to request a personalized quote, please visit our Contact Us – Langir page and connect directly with our dedicated sales team.

What Case Studies Showcase Langir’s Capacitive Switch Success Stories?

One prominent automotive supplier achieved a remarkable 75 percent reduction in console failures after retrofitting their stamping machines with advanced capacitive controls. A major food-packaging line successfully cut cleaning downtime by half by transitioning to glass-overlay capacitive buttons, which withstand daily high-pressure washdowns. These tangible, real-world results powerfully demonstrate how Langir’s innovative solutions drive significant improvements in productivity and operational reliability.

What Are the Current Market Trends and Future Outlook for Capacitive Contact Sensing

Capacitive sensing is poised for substantial growth, fueled by the accelerating global adoption of industrial automation and the increasing demand for touchless interfaces. Innovations in advanced materials, AI-driven calibration techniques, and seamless IoT connectivity are continuously expanding the technology’s capabilities. Let’s examine the current market dynamics and exciting emerging innovations.

Get a quote for custom capacitive switches from Langir

How Is the Global Capacitive Sensor Market Expanding in Industrial Automation?

The global capacitive sensor market achieved a valuation of $35.15 billion in 2023 and is projected to experience robust growth, reaching an estimated $56.45 billion by 2031, expanding at a compound annual growth rate (CAGR) of 6.1 percent.

Key factors driving this expansion include:

- The increasing integration of smart factories and Industry 4.0 systems

- A growing demand for sealed, low-maintenance input devices

- The continued expansion of touchless solutions, particularly post-pandemic

Capacitive Sensor Market Growth Projections

The global capacitive sensor market is forecasted for significant expansion, with an anticipated compound annual growth rate (CAGR) of 6.7% between 2025 and 2035, driven by escalating demand across various sectors, including industrial automation.

What Emerging Technologies and Applications Are Shaping Capacitive Sensing?

Cutting-edge innovations such as machine-learning-based noise rejection algorithms, highly flexible stretchable electrode arrays, and integrated IoT telemetry are significantly broadening the scope of capacitive sensing applications. Examples include gesture recognition for AR/VR-assisted maintenance tasks and embedded fluid-quality analysis utilizing multi-parameter sensors. These advancements signal the dawn of a more intelligent and interconnected era for industrial HMIs.

How Does Capacitive Sensing Compare to Other Sensor Technologies in Industrial Use?

Capacitive solutions truly shine in applications where multi-material detection and robust environmental sealing are paramount, setting them apart from technologies like inductive sensors (which focus on metal detection) and piezoelectric sensors (which detect pressure and vibration).

What Common Questions Do Industrial Users Have About Capacitive Contact Sensing

Industrial engineers frequently seek detailed information regarding detection range, environmental limitations, and best-practice design guidelines before implementing capacitive solutions. Addressing these key concerns ensures a smoother integration process and guarantees reliable, long-term performance. Here are four frequently asked questions.

Can Capacitive Contact Sensing Detect Both Metallic and Non-Metallic Objects?

Yes, capacitive sensors are designed to respond to any material with a dielectric constant greater than that of air. This capability allows for the detection of a wide range of materials, including metals, plastics, glass, and liquids. By precisely adjusting the electrode size and drive frequency, engineers can calibrate the sensitivity to reliably distinguish targets regardless of their composition, supporting highly versatile object-presence applications on assembly lines.

What Are the Limitations and Challenges of Capacitive Sensing in Industrial Environments?

Capacitive sensing performance can be influenced by extreme humidity or the presence of condensation, necessitating careful calibration and robust waterproof sealing. In environments with high levels of electromagnetic interference (EMI), shielded layouts and advanced firmware filtering are crucial to prevent false triggers. Additionally, large nearby metal panels can alter the baseline capacitance, requiring designers to carefully consider surrounding structures. However, with proper layout design and precise tuning, these challenges can be effectively overcome.

How Does Capacitive Sensing Enhance Human-Machine Interfaces in Industrial Settings?

Capacitive interfaces provide consistent activation force, customizable backlighting options, and integrated haptic feedback, all without the seams or crevices that can trap contaminants. Their low-profile design allows for seamless integration into flush panels, simplifying cleaning and sterilization processes. Operators benefit from intuitive controls that reduce training time and minimize input errors, ultimately boosting overall productivity and operational safety.

How Can Industrial Engineers Optimize Capacitive Sensor Design for Maximum Reliability?

Engineers should implement robust design practices such as ground guards, dedicated return paths, and differential sensing techniques to effectively minimize parasitic capacitance. PCB layouts must meticulously isolate high-voltage or power circuits from sensitive sensor traces. Furthermore, firmware thresholds should be dynamically adapted to account for ambient temperature and humidity shifts. Implementing routine calibration during scheduled maintenance cycles is essential for ensuring long-term stability and preventing performance drift in critical operations.

Capacitive contact sensing has evolved into a highly reliable and remarkably flexible solution, perfectly equipped to meet the rigorous demands of modern industrial automation.

Capacitive contact sensing delivers unparalleled durability, extensive design freedom, and versatile detection capabilities essential for challenging factory environments. Langir’s specialized expertise in bulk-order capacitive push button switches and comprehensive end-to-end customization brings these significant advantages directly to your production line. Whether your needs involve sealed glass overlays for demanding wash-down stations or sophisticated multi-touch keypads for robotic applications, capacitive technology offers a clear path to elevating both reliability and user experience. Contact Langir today to explore tailored capacitive switch solutions for your next critical automation project.

EN

EN

26/09/2025

26/09/2025