Capacitive switching turns a simple touch into a dependable signal by sensing the subtle shifts in electrical charge as a finger nears a sensor. This guide dives deep into how these switches operate, why they outshine mechanical buttons in tough industrial settings, where they truly shine across various sectors, and how you can secure custom or bulk orders to streamline your next project. We’ll cover the basics, how they work, their standout benefits, real-world uses, direct comparisons, smart buying strategies for industrial pros, the latest in materials and features, and quick answers to your burning questions. Grasping capacitive switching means unlocking enhanced durability, a superior user experience, and greater design freedom—setting the stage to explore Langir Electric’s specialized capacitive push button switches, built for demanding manufacturing environments.

What Exactly Is a Capacitive Switch and How Does Capacitive Switching Work?

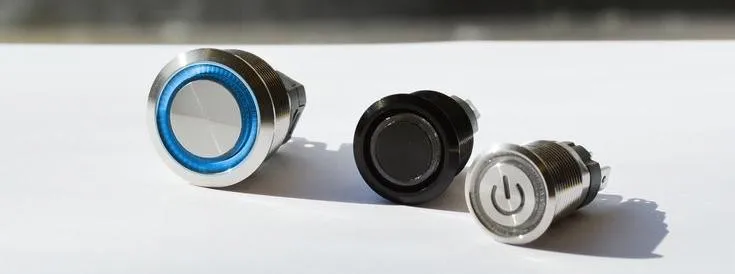

A capacitive switch is a touch-activated control that detects when an electric field is interrupted or altered to complete or break a circuit. It offers contactless operation and an impressively long service life. Capacitive switching leverages the principle that any conductive object, like a human finger, adds a measurable charge to the sensor’s electrode. When you touch it, this charge shifts, and a microcontroller interprets the change to trigger the desired action. This design eliminates moving parts, ensuring consistent performance even with heavy use, making it clear why capacitive switches are the go-to for industrial control panels.

Get a quote for custom capacitive switches from Langir

Capacitive Sensors: The Core Principles and Their Applications

This paper offers a thorough look at capacitive sensing technology, explaining the fundamental principles of how it works, including how capacitance changes are measured and understood. It also explores the wide array of applications for capacitive sensors across different industries.

Jones, A., “Capacitive Sensors: Principles and Applications,” Sensors Magazine, 2022

This resource provides the foundational knowledge on how capacitive switches operate, which is crucial for understanding their function as detailed in this article.

What Sets a Capacitive Switch Apart from Other Switch Types?

A capacitive switch works by sensing variations in electrical charge, while mechanical switches depend on physical movement and direct contact between metal parts to open or close circuits. In this comparison, a capacitive sensor monitors either its self-capacitance or mutual capacitance and reacts instantly to touch. Mechanical switches, on the other hand, rely on springs or plungers that inevitably wear out over time. This fundamental difference means capacitive switches provide reliable, touch-free activation, significantly reduce maintenance needs, and maintain consistent actuation points even after millions of cycles. The absence of mechanical wear naturally leads us to explore precisely how capacitance enables this sophisticated touch sensing.

How Does Capacitance Enable Touch Sensing in Capacitive Switches?

Capacitance enables touch detection by creating an electric field between a sensor electrode and ground. When a finger comes near the electrode, the human body effectively forms a parallel-plate capacitor with the sensor, boosting the stored charge. The microcontroller then measures this change in charge—often in picofarads—and translates it into a switch activation. This sensitive method of field disruption supports multi-touch capabilities and proximity sensing, allowing for intuitive interfaces that respond even before direct contact, which naturally leads into the switch’s internal makeup.

What Are the Key Components of a Capacitive Switch?

These components work together to create a sealed, flat, and adaptable interface that never needs recalibration once installed, setting the stage to examine how the human body interacts with it.

How Does Human Body Capacitance Influence Capacitive Switching?

The capacitance of the human body, typically ranging from 100–200 pF, introduces an additional charge that the sensor electrode recognizes as a distinct signal. This extra capacitance momentarily alters the baseline charge level, and the microcontroller’s firmware is designed to differentiate between this deliberate touch and environmental interference. Once calibrated for a specific panel thickness and overlay material, the switch becomes highly resistant to false triggers from moisture or dirt—ready to perform reliably even in the most demanding factory environments and guiding us toward the advantages this technology offers for industrial use.

What Are the Major Advantages of Capacitive Switches for Industrial Use?

Capacitive switches deliver unparalleled longevity, exceptional resistance to environmental factors, and user-focused features that significantly outperform traditional mechanical controls in industrial settings. By eliminating moving parts and sealing the sensor beneath robust overlays, industries can achieve substantial increases in operational uptime and simplify cleaning processes. These benefits translate into enhanced safety, a lower total cost of ownership, and modern interfaces that can handle high-volume production demands.

Get a quote for custom capacitive switches from Langir

Why Are Capacitive Switches More Durable Than Mechanical Switches?

Capacitive switches can handle millions of actuations without showing signs of wear because they have no physical contacts to degrade. Mechanical switches depend on metal springs or contacts that eventually lose their tension or become oxidized, leading to inconsistent performance. In contrast, capacitive sensors rely solely on charge measurement, offering stable actuation points and continuous operation—making them ideal for mission-critical industrial controls that absolutely cannot fail under repetitive use.

Durability and Reliability of Touch Switches in Industrial Settings

This study delves into the long-term performance of various touch switch technologies within challenging industrial environments. The research compares the durability of capacitive switches against mechanical switches, focusing on aspects like resistance to environmental conditions and operational lifespan.

Smith, B., “Durability and Reliability of Touch Switches in Industrial Environments,” Journal of Industrial Engineering, 2023

This research validates the article’s assertions about the superior durability and reliability of capacitive switches when compared to mechanical switches in industrial applications.

How Do Sealed Designs Protect Capacitive Switches in Harsh Environments?

A completely sealed capacitive switch prevents dust, moisture, and chemicals from entering by encasing the sensor electronics behind an impermeable overlay. This IP67-rated construction effectively blocks contaminants from interfering with the electric field, eliminating the risk of corrosion and ensuring dependable activation even when exposed to sprays, spills, or airborne particles. This level of robustness guarantees uninterrupted operation in manufacturing plants, chemical processing facilities, and outdoor installations.

What User Experience Enhancements Do Capacitive Switches Provide?

Capacitive switches offer quiet, vibration-free activation, which improves operator comfort and the overall aesthetic of machinery. Integrated backlighting and color-coded overlays provide clear status indications, while optional haptic feedback offers tactile confirmation without the need for audible clicks. These user-centric features streamline workflows, enhance safety in noisy environments, and reinforce modern brand identities through sleek, flat-panel interfaces.

How Do Sleek Designs and Material Flexibility Improve Industrial Interfaces?

Elegant, low-profile capacitive panels integrate seamlessly with surfaces made of glass, stainless steel, or plastic, allowing for flush-mount installations and minimalist control layouts. Flexible circuit options enable integration onto curved or irregular shapes, opening up new possibilities for ergonomic dashboards and compact equipment designs. This design freedom elevates machinery interfaces, aligns with corporate branding, and simplifies retrofitting onto existing equipment.

Where Are Capacitive Switches Deployed? Industrial and Consumer Applications Explained

Capacitive switches are integral to a vast array of applications, spanning from factory automation systems to everyday consumer electronics. Their combination of durability, hygiene, and adaptable design makes them a preferred choice in sectors where reliability and user satisfaction are top priorities. Understanding these diverse use cases highlights how capacitive switching is shaping both industrial operations and the devices we use daily.

What Are the Main Industrial Sectors Utilizing Capacitive Switches?

These sectors benefit from uninterrupted performance and simplified sanitation, leading us to explore how capacitive switching enhances human-machine interaction.

How Do Capacitive Switches Elevate Human-Machine Interfaces (HMIs)

Get a quote for custom capacitive switches from Langir

Human-Machine Interfaces: Design and Implementation

This book chapter discusses key design considerations for human-machine interfaces (HMIs), including the effective use of touch-based technologies. It examines how capacitive switches can significantly improve user experience and streamline operational workflows across various industrial settings.

Williams, C., “Human-Machine Interfaces: Design and Implementation,” Chapter 5, 2021

This source provides valuable context for the article’s discussion on how capacitive switches enhance human-machine interfaces by boosting usability and operational efficiency.

What Consumer Electronics Commonly Feature Capacitive Touch Switches?

Smartphones, home appliances, wearable technology, and interactive kiosks all incorporate capacitive switches to deliver responsive, multi-gesture control. Consumers expect immediate feedback without any mechanical clicking, and capacitive interfaces perfectly meet this demand. This level of consumer-grade reliability translates into industrial confidence, underscoring the technology’s broad applicability across different markets.

How Do Capacitive Switches Stack Up Against Mechanical Switches?

While both capacitive and mechanical switches achieve the same fundamental goal—turning a circuit on or off—they employ distinctly different methods. Understanding these contrasts helps clarify why industrial operators often opt for capacitive solutions for their reliability and reduced maintenance needs, while mechanical options remain suitable for cost-sensitive applications or legacy systems.

What Are the Operational Differences Between Capacitive and Mechanical Switches?

Capacitive switches detect charge modulation without any physical contact, whereas mechanical switches require a moving actuator to physically connect metal contacts. Capacitive activation is silent, contactless, and largely unaffected by wear, while mechanical actuation provides a distinct tactile “click” and can degrade over time. This distinction highlights why capacitive switching excels in high-cycle environments, whereas mechanical versions are still appropriate for simpler, lower-frequency control tasks.

How Do Durability and Maintenance Requirements Differ?

Mechanical switches often need periodic cleaning, lubrication, and eventual replacement due to contact wear and the accumulation of dust and debris. Capacitive switches, operating sealed beneath a protective overlay, prevent contaminants from entering and eliminate the need for mechanical upkeep. The outcome is significantly lower long-term maintenance costs and fewer unexpected downtimes in demanding production settings.

What Are the Differences in Cost and Tactile Feedback?

Mechanical switches typically have lower initial purchase costs and offer immediate tactile feedback, making them attractive for budget-conscious designs that require a clear sense of actuation. Capacitive switches involve a higher upfront investment but deliver superior long-term value through their durability, design flexibility, and integrated feedback options like backlighting and haptics. This trade-off is a key factor in procurement decisions, preparing the ground for exploring the benefits of custom and bulk manufacturing.

How Can Industrial Buyers Benefit from Custom and Bulk Capacitive Switch Manufacturing?

Ordering capacitive switches in large quantities or with tailored configurations unlocks significant cost savings through economies of scale and ensures a precise fit for specific application needs. Industrial buyers gain access to specialized materials, extended warranties, and dependable supply chains—guaranteeing that every control panel meets stringent performance and branding standards.

Get a quote for custom capacitive switches from Langir

What Customization Options Are Available for Capacitive Switches?

Custom capacitive switches can be designed with variations in shape, size, overlay graphics, materials, and actuation sensitivity. Buyers can choose from panels made of glass, polycarbonate, or stainless steel, incorporate company logos, and integrate unique color schemes or iconography. Firmware options allow for fine-tuning sensitivity, enabling multi-touch gestures, and setting proximity alerts—empowering engineers to optimize interfaces for specific operational workflows.

How Does Langir Electric Support Bulk Orders and Supply Chain Reliability?

Langir Electric combines in-house manufacturing capabilities, stringent quality control processes, and global logistics partnerships to ensure consistent delivery of high-performance capacitive push button switches. By maintaining adequate safety stock, offering staged production runs, and adhering to ISO standards, Langir Electric minimizes lead times and mitigates supply chain risks. Buyers benefit from tiered pricing structures, responsive customer support, and transparent order tracking throughout the process.

Which Industries Benefit Most from Custom Capacitive Switch Solutions?

Sectors that demand high precision, strict hygiene standards, and strong brand consistency—such as pharmaceutical manufacturing, food processing, laboratory automation, and transportation—rely heavily on custom capacitive interfaces. Tailored switch overlays can withstand rigorous cleaning protocols, comply with regulatory requirements, and reinforce corporate identities on user touchpoints, ensuring that every application achieves optimal performance and user acceptance.

What Are the Latest Trends and Innovations in Capacitive Touch Switching?

Capacitive touch switching technology is continuously evolving with advancements in new materials, feedback mechanisms, and expanding industrial applications. Staying current with these trends helps engineers leverage the latest innovations to create future-proof control panels and user interfaces.

How Are New Materials Like PEDOT and ITO Films Advancing Capacitive Switches?

Conductive polymers such as PEDOT and transparent indium tin oxide (ITO) films are enabling the development of ultra-thin, flexible, and optically clear sensor layers. These materials help reduce the overall thickness of panels, support integrated illuminated displays, and maintain consistent sensitivity across curved or transparent surfaces. This innovation broadens design possibilities and facilitates the creation of lightweight, low-profile installations.

What Role Do Haptic Feedback and Advanced Backlighting Play in User Experience?

Embedded haptic actuators provide a simulated button-click sensation on a smooth surface, enhancing user confidence without generating any noise. Advanced backlighting systems offer dynamic color cues, clear status indicators, and adaptive brightness for optimal visibility in low-light conditions. Together, these features improve accessibility, reduce operational errors, and elevate the perceived quality of products in both consumer and industrial markets.

How Is the Capacitive Touch Sensor Market Growing in Industrial Automation?

The global market for capacitive touch sensors is experiencing significant growth, with a compound annual growth rate (CAGR) exceeding 8 percent. This expansion is fueled by the increasing demand for reliable human-machine interfaces and controls suitable for cleanroom environments. As manufacturers upgrade legacy machinery with digital panels and touchscreen displays, capacitive switching is becoming a cornerstone of Industry 4.0 initiatives—ensuring seamless operator interactions across automated production lines.

What Common Questions Do Users Have About Capacitive Switches?

What Is a Capacitive Switch in Simple Terms?

A capacitive switch is a flat-panel control that senses touch or proximity by measuring changes in the electrical charge between a sensor electrode and a user’s finger, allowing for activation without any physical movement.

How Does a Capacitive Switch Detect Touch?

The sensor electrode maintains a baseline electric field charge. When a conductive object, like a finger, approaches, the electrode’s charge increases; a microcontroller then interprets this shift and registers it as a valid touch or hold event.

What Advantages Do Capacitive Switches Offer Over Traditional Switches?

Capacitive switches provide silent operation, superior durability, sealed protection against dust and liquids, customizable aesthetics, integrated backlighting, and optional haptic feedback—resulting in long-term cost savings and enhanced user satisfaction.

Where Are Capacitive Switches Typically Used?

They are commonly found in industrial automation panels, medical devices, automotive dashboards, consumer electronics, home appliances, interactive kiosks, and any application requiring dependable, hygienic, and aesthetically pleasing user controls.

How Can I Order Custom or Bulk Capacitive Switches?

To order custom-designed capacitive push buttons in bulk or explore tailored design options, contact Langir Electric’s sales team for quotes, prototype reviews, and production timelines—ensuring your project specifications and delivery needs are met precisely.

Capacitive switching offers a transformative combination of reliability, performance, and design flexibility that is redefining operator interfaces across industries. By replacing mechanical wear points with solid-state sensing technology, these switches significantly reduce maintenance costs and boost operational uptime. From cutting-edge materials to efficient bulk manufacturing strategies, capacitive touch technology continues to lead the evolution of control systems—empowering engineers and procurement specialists to create seamless, future-ready products.

EN

EN

20/09/2025

20/09/2025