In demanding healthcare environments, device interfaces must offer precision, durability, and sterility. Capacitive touch switches excel in all three. Utilizing an electric-field sensing method, these solid-state switches register contact without moving parts, inherently resisting contaminants, simplifying rigorous cleaning, and enabling intuitive control even with gloved hands. This comprehensive guide will delve into:

- The operational principles of capacitive touch switches in medical applications

- Critical advantages in hygiene and infection control

- Durability features that significantly reduce maintenance costs

- Enhanced user experience and safety improvements

- Key technical benefits and Langir’s customization capabilities

- Prevalent medical device applications

- Why Langir is the ideal partner for your bulk and custom solutions

Explore why leading hospitals, laboratories, and medical device manufacturers globally are adopting capacitive technology to elevate patient care and optimize operational efficiency.

Capacitive Touch Switches: Core Functionality in Medical Device Integration

Capacitive touch switches operate by detecting minute changes in capacitance when a conductive object, such as a fingertip, approaches a sensing electrode. This principle translates subtle electric-field shifts into a highly reliable on-off signal, perfectly suited for sterile medical controls. This solid-state methodology eliminates mechanical wear and potential contamination points, ensuring precise actuation feedback for critical medical equipment.

Get a quote for custom capacitive switches from Langir

Capacitive Touch Technology: Principles for Medical Device Implementation

Capacitive touch technology employs an electrode matrix positioned beneath a non-conductive surface to detect changes in capacitance as a conductive object approaches a sensing electrode. This advanced method translates subtle electric-field shifts into a dependable on-off signal, making it optimal for sterile medical controls by eliminating mechanical wear and potential contamination pathways.

Langir, Capacitive Touch Switches for Medical Devices (2024)

This citation substantiates the detailed explanation of capacitive touch switch functionality within medical device applications.

Understanding Capacitive Touch Technology and Its Sensing Principles

Capacitive touch technology relies on an electrode matrix beneath a non-conductive surface (glass or plastic) that continuously measures an electric field.

- Definition: A precisely engineered sensor grid establishes a baseline electrical charge.

- Mechanism: The introduction of a conductive object, such as a human finger, alters the local capacitance within the electric field.

- Benefit: The integrated controller accurately interprets these capacitance shifts, resulting in consistent and reliable switch activations without any physical movement or travel.

This fundamental principle ensures highly responsive and precise inputs across critical medical equipment, including infusion pumps, patient monitors, and advanced imaging consoles. A thorough understanding of this sensing method naturally leads to a comparative analysis with conventional mechanical control interfaces.

Capacitive vs. Traditional Mechanical Switches: A Comparative Analysis for Medical Applications

The following table provides a direct comparison of capacitive touch switches against conventional mechanical membrane and push-button switches, specifically within medical environments.

Capacitive devices demonstrably outperform their mechanical counterparts by eliminating friction points and inherent contamination traps. This design innovation facilitates seamless cleaning protocols and ensures a significantly extended service life. This foundational durability directly underpins their superior hygienic advantages.

Optimizing Medical Device User Interfaces with Capacitive Sensing

- Glove-Friendly Operation: Accurately recognizes insulated touches, eliminating the need for recalibration or glove removal.

- Silent Actuation: Completely eliminates audible clicks, significantly reducing noise pollution in sensitive patient care environments.

- Exceptional Precision: Detects even the lightest touches, effectively minimizing the risk of accidental activations and ensuring accurate input.

These inherent attributes collectively deliver a user interface that not only adheres to stringent sterile-environment protocols but also significantly enhances overall workflow safety. This sets the foundation for a comprehensive examination of their profound infection-control advantages.

Capacitive Touch Switches: Elevating Hygiene and Infection Control in Healthcare Environments

Capacitive touch switches are engineered with fully sealed surfaces, effectively preventing fluid ingress and eliminating microbial harboring points. This design empowers medical staff to maintain sterile conditions with unparalleled effectiveness. Their inherently smooth, non-porous overlays actively resist contamination and are built to withstand rigorous disinfection protocols, directly mitigating the risks of hospital-acquired infections (HAIs).

Get a quote for custom capacitive switches from Langir

Key Advantages in Hygiene and Infection Control

Capacitive touch switches incorporate sealed surface designs that actively prevent fluid penetration and inhibit microbial proliferation. This critical feature enables medical personnel to uphold stringent sterile conditions with enhanced efficiency. The smooth, non-porous overlay materials inherently resist contamination and are proven to endure aggressive disinfection regimens, thereby directly contributing to a significant reduction in hospital-acquired infection (HAI) rates.

Langir, Capacitive Touch Switches for Medical Devices (2024)

This reference substantiates the assertions regarding the profound hygiene benefits of capacitive touch switches within diverse healthcare environments.

Preventing Hospital-Acquired Infections with Sealed Capacitive Touch Surfaces

- Superior Fluid Resistance: Achieves Ingress Protection (IP) ratings up to IP67, ensuring complete impermeability to liquids and disinfectants.

- Non-Porous Surface Integrity: Eliminates microscopic crevices or seams where pathogens could harbor and proliferate.

- Effortless Disinfection: Facilitates rapid and thorough cleaning with alcohol-based solutions, instantly removing contaminants and ensuring a sterile interface.

By effectively preventing the proliferation of bacteria and viruses directly at the interface, these advanced switches are instrumental in maintaining the pristine sterility required in operating rooms and intensive care units. Our next section will detail compatible sterilization methodologies.

Compatible Sterilization Methods for Capacitive Touch Panels

- Chemical Disinfectants: Fully compatible with common hospital-grade solutions, including isopropyl alcohol and quaternary ammonium wipes.

- UV-C Irradiation: Withstands non-contact germicidal exposure for comprehensive surface sterilization.

- Steam Autoclaving: Available for specialized panels engineered to endure high-temperature steam sterilization cycles.

These validated sterilization methods ensure the integrity of the underlying electrode layer while effectively eradicating harmful microorganisms. The inherent compatibility with aggressive disinfectants underscores the critical importance of smooth, non-porous surface designs.

The Critical Role of Smooth, Non-Porous Surfaces in Medical Hygiene

- Significantly Reduced Bacterial Load: The absence of cracks, seams, or joints eliminates potential harborage points for pathogens.

- Exceptional Chemical Resilience: Engineered to withstand repeated exposure to potent, hospital-grade cleaning agents without degradation.

- Ensured Consistent Disinfection: Facilitates uniform wipe-down procedures, effectively eliminating hotspots and ensuring comprehensive surface sterilization.

This inherent material advantage forms the cornerstone of rigorous infection-control standards and seamlessly transitions into the discussion of their unparalleled long-term reliability and durability.

Unmatched Durability and Reliability of Capacitive Touch Switches in Medical Environments

Capacitive touch switches are engineered to robustly resist the harsh chemical agents, pervasive moisture, and significant mechanical stress inherent to healthcare settings, ensuring years of virtually maintenance-free operation. Their advanced solid-state design is built to withstand frequent, rigorous cleaning cycles and continuous, high-demand use, thereby substantially driving down the total cost of ownership.

Get a quote for custom capacitive switches from Langir

Resistance to Wear, Chemicals, and Moisture: The Capacitive Advantage

- Solid-State Sensor Design: Eliminates all moving parts, preventing mechanical fatigue and wear over time.

- Advanced Protective Overlays: Utilizes chemically inert glass or specially coated plastics, offering superior resistance to aggressive cleaning agents.

- Hermetically Sealed Assembly: Incorporates conformal coatings and precision sealing to completely block moisture ingress and environmental contaminants.

This inherently robust construction guarantees consistent, uninterrupted performance across a wide range of critical medical applications, including dialysis stations, advanced critical-care monitors, and portable diagnostic tools. Sustaining this level of reliability necessitates adherence to globally recognized protection standards.

IP Ratings and Rugged Features for Medical Device Longevity

- IP67 or Higher Ingress Protection: Ensures complete protection against dust ingress and temporary immersion in liquids, crucial for sterile environments.

- IK07 Impact Resistance Rating: Provides robust protection against mechanical impacts and accidental knocks, common in dynamic clinical settings.

- Extended Operating Temperature Range: Guarantees reliable functionality across a broad spectrum of temperatures, from –20 °C to +70 °C, accommodating diverse operational conditions.

These stringent ratings collectively guarantee uninterrupted service and optimal performance in a vast array of medical applications, ranging from demanding outdoor triage units to sensitive neonatal incubators. Furthermore, this exceptional durability translates into substantial cost savings throughout a device’s entire operational lifecycle.

Reducing Total Cost of Ownership Through Enhanced Durability in Medical Equipment

- Minimized Replacements: Leads to significantly reduced procurement cycles and capital expenditure.

- Reduced Maintenance Requirements: Requires minimal labor and fewer replacement parts, optimizing operational budgets.

- Maximized Uptime Fewer device failures directly translate to enhanced operational continuity and a reduction in critical treatment delays.

By seamlessly combining a rugged, resilient design with effortless cleaning capabilities, capacitive switches effectively reduce operational expenses and enable technical staff to focus on higher-value tasks. This synergy perfectly aligns with the pursuit of enhanced user experience and paramount safety within demanding clinical settings.

Optimizing User Experience and Safety with Capacitive Touch Switches in Medical Environments

Capacitive touch switches provide highly intuitive controls that significantly accelerate clinical workflows, minimize input errors, and instill greater confidence in medical professionals. Their silent operation and precise sensitivity directly contribute to safer procedures, while thoughtfully designed ergonomic overlays effectively minimize operator fatigue during prolonged periods of use.

Get a quote for custom capacitive switches from Langir

The Indispensable Nature of Glove-Friendly Operation for Medical Professionals

- Consistent, Reliable Activation: Eliminates the necessity of removing gloves or recalibrating the interface, ensuring uninterrupted workflow.

- Minimized Cross-Contamination Risk: Facilitates continuous glove coverage, thereby significantly reducing the potential for pathogen transfer.

- Accelerated Task Completion: Eliminates the common fumbling and inaccuracies often associated with traditional resistive screens, enhancing efficiency.

This seamless glove compatibility is fundamental to achieving faster patient turnarounds and facilitating smoother, more efficient workflow transitions. This critical advantage naturally leads to an exploration of how highly intuitive interfaces inherently reduce operational errors.

Enhancing Patient Care and Reducing Errors Through Intuitive Interfaces

- Clear Visual Cues: Backlit legends and icons provide unambiguous guidance for button functions, even in challenging low-light clinical environments.

- Tactile Confirmation: Optional soft haptic feedback provides immediate, reassuring confirmation of selections, enhancing user confidence.

- Robust Error Prevention: Advanced multi-touch rejection algorithms effectively prevent accidental or unintended inputs, ensuring precise control.

When control actions are unequivocally clear and unambiguous, clinicians can dedicate less time to second-guessing settings and more time to direct patient care. Our subsequent discussion will delve into ergonomic design elements that further elevate overall usability.

Ergonomic Design Features for Enhanced Medical Device Usability

- Low-Profile Overlays: Engineered to prevent knuckle interference and minimize user strain during prolonged interaction.

- Soft-Touch Finishes: Provide comfortable and tactile contact surfaces, enhancing the user’s experience.

- Custom Contours and Form Factors: Designed to seamlessly align with specific device enclosures, ensuring natural and intuitive reach for optimal control.

These meticulously engineered, user-centered design elements significantly reduce operator fatigue in high-demand environments such as operating suites and radiology rooms. This directly correlates with the underlying technical advantages that robustly support their superior performance.

Technical Advantages & Customization Options for Medical-Grade Capacitive Touch Switches

Beyond their inherent hygiene and ergonomic benefits, capacitive switches deliver critical technical advantages, including superior electromagnetic immunity, robust electrostatic discharge protection, and highly adaptable form factors. These attributes are indispensable for medical OEMs developing specialized instruments. Langir’s comprehensive services ensure that each custom solution precisely aligns with exact device specifications and performance requirements.

Ensuring EMI and ESD Protection in Sensitive Medical Environments with Capacitive Switches

- Mitigate Electromagnetic Interference (EMI): Crucially maintains signal integrity and prevents operational disruption when positioned near sensitive imaging and radiofrequency (RF) equipment.

- Suppress Electrostatic Discharge (ESD): Provides robust protection for internal electronics against accidental static shocks, safeguarding device longevity.

- Ensure EMC Standards Compliance: Guarantees reliable and safe operation within electromagnetically sensitive environments, including MRI and CT suites.

This inherent technical robustness is paramount in preventing data corruption and mitigating device malfunctions, thereby reinforcing the foundation for safe, accurate, and reliable diagnostic procedures.

Langir’s Comprehensive Customization Services for Medical Capacitive Switches

- Custom Graphic Overlay Design: Offers tailored legends, intuitive icons, and integrated backlighting solutions to meet specific interface requirements.

- Rapid Prototyping and Rigorous Validation: Provides swift sample production and comprehensive functional testing to accelerate development cycles.

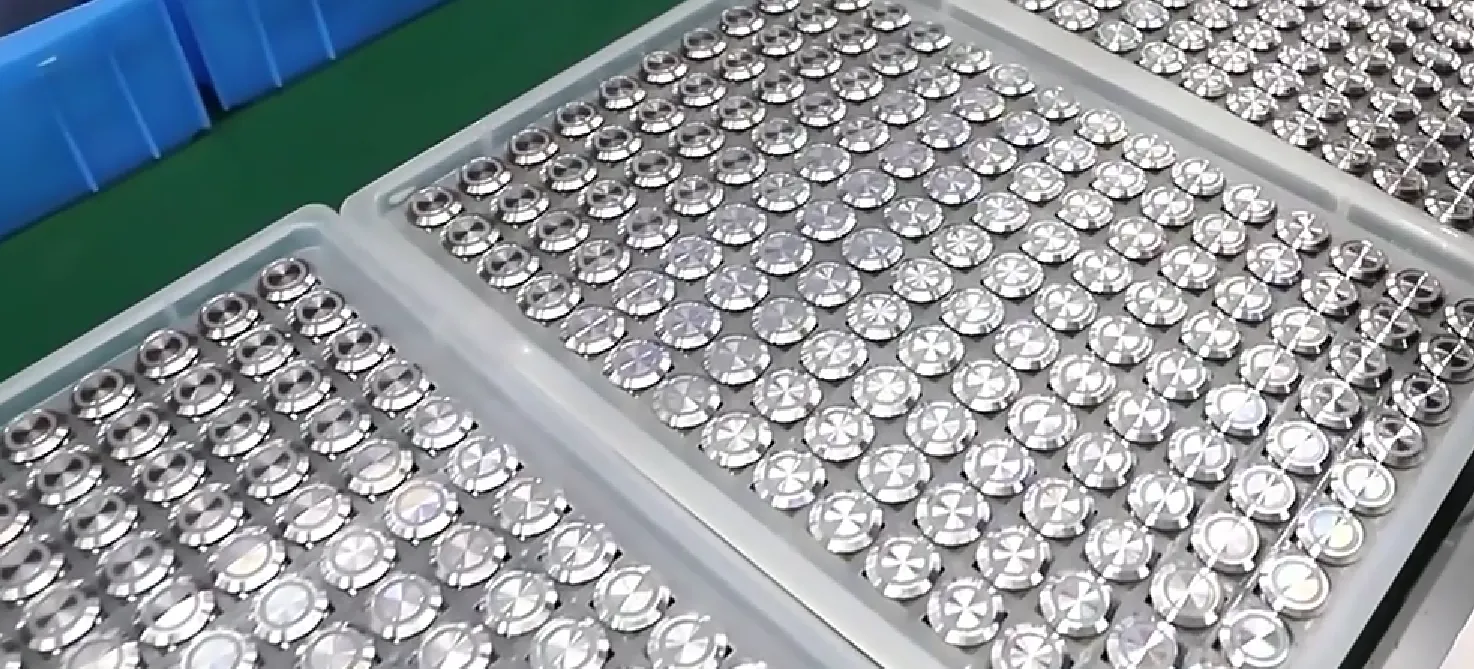

- Scalable Volume Manufacturing: Ensures high-volume production capabilities with unwavering quality consistency for large-scale OEM projects.

- Regulatory Certification Support: Offers expert assistance with critical medical standards compliance, including IEC 60601 and ISO 13485.

Our streamlined, turnkey process significantly accelerates your time-to-market while meticulously ensuring that every panel rigorously adheres to stringent medical safety and performance criteria.

Available Materials and Form Factors for Medical-Grade Capacitive Switches

These versatile material and form factor options are designed to seamlessly accommodate diverse device architectures and stringent sterilization protocols. This comprehensive range naturally leads us to explore real-world implementations across various medical equipment categories.

Common Medical Device Applications of Capacitive Touch Switches & Their Benefits

Capacitive switches are widely integrated across a broad spectrum of diagnostic, monitoring, surgical, and laboratory devices, primarily due to their unparalleled advantages in hygiene, reliability, and precision. The strategic integration of these advanced switches demonstrably elevates both clinical safety standards and overall user satisfaction.

Get a quote for custom capacitive switches from Langir

Integration of Capacitive Switches in Diagnostic Imaging Equipment

- Facilitate Seamless Cleaning: Essential for maintaining sterile conditions and rapid patient turnover after each use.

- Minimize Acoustic Noise: Crucial for creating a calm and reassuring environment within sensitive imaging rooms.

- Enable Rapid Parameter Adjustments: Allows for precise, real-time tuning of critical parameters, enhancing diagnostic efficiency.

Their fully sealed overlays provide robust protection for sensitive internal electronics against gels and aggressive cleaning fluids, thereby ensuring uninterrupted and reliable diagnostic performance.

Suitability of Capacitive Touch Interfaces for Patient Monitoring Systems

- Enable Rapid Parameter Adjustments: Facilitates swift modifications to critical patient data, such as heart rate, oxygen saturation levels, and infusion rates.

- Support Gloved Operation: Allows nurses and respiratory therapists to maintain continuous barrier precautions without compromising interface functionality.

- Provide Clear Status Indicators: Integrated backlit icons instantly highlight critical alarms and operational statuses, ensuring immediate caregiver response.

This synergistic combination of operational clarity and inherent sterility empowers caregivers to respond with greater speed and precision to evolving patient needs.

Benefits of Capacitive Switches in Surgical and Laboratory Devices

- Optimize Sterilization Cycles: Engineered to withstand repeated, rigorous autoclave or UV-C germicidal treatments without degradation.

- Elevate Precision Control: Detects even the most minimal touches, enabling precise micro-adjustments critical for delicate procedures.

- Ensure Unwavering Reliability: Designed to endure high-traffic, continuous use environments without susceptibility to mechanical failure.

These highly demanding domains necessitate uninterrupted hygiene protocols and consistently flawless performance throughout critical procedures, unequivocally underscoring the profound value and strategic advantage of capacitive design.

Why Langir is Your Premier Partner for Medical-Grade Capacitive Touch Solutions

Langir uniquely combines profound expertise in capacitive switch technology with comprehensive, end-to-end manufacturing capabilities. This synergy enables us to deliver medical-grade panels that not only meet the most stringent regulatory standards but also fulfill the precise volume requirements of leading healthcare OEMs globally.

Langir Capacitive Switches: Adherence to Key Medical Standards and Certifications

- IEC 60601-1: Compliance with international electrical safety standards for medical electrical equipment.

- ISO 13485: Certified quality anagement system specifically for medical devices.

- IP67: Achieves superior ingress protection against dust and temporary immersion.

- RoHS and REACH:** Adherence to critical environmental and material safety directives.

Langir’s Support for Bulk Procurement and Tailored Medical Solutions

- Highly Competitive Volume Pricing: Optimized to provide significant cost efficiencies for large-scale OEM contracts.

- Agile Production & Rapid Changeover: Features streamlined workflows designed for efficient adaptation to varied and complex designs.

- Dedicated Account Management: Offers a single, expert point of contact for seamless order coordination and project oversight.

Our unwavering B2B focus guarantees highly reliable supply chains and provides comprehensive, customized documentation tailored precisely for each medical device manufacturing partner.

Requesting Quotes & Contacting Langir for Medical Device Manufacturers

To explore our extensive range of bulk capacitive switch options or to discuss a bespoke custom design, we invite you to request a consultation and detailed quote by visiting Langir’s dedicated contact page: Connect with Langir: Bulk Orders & Custom Medical Capacitive Switches

Capacitive touch switches unequivocally deliver unmatched levels of hygiene, exceptional durability, and highly intuitive controls, aligning perfectly with the rigorous demands of modern medical devices. Their inherent ability to robustly resist harsh chemicals, effectively prevent contamination, and provide precise, glove-compatible operation directly translates into significantly reduced maintenance costs and profoundly enhanced patient care. Langir’s unparalleled expertise in advanced customization and high-volume manufacturing ensures that you will secure reliable, certified panels meticulously tailored to your exact specifications. We encourage you to connect with us today to seamlessly integrate advanced capacitive technology into your next groundbreaking medical device project.

EN

EN

16/09/2025

16/09/2025