It is important to understand the normally open vs normally closed switches debate, as they determine the behavior of an electric system. Closed or open states indicate whether a switch allows or blocks the current flow. Whether you’re an engineer, hobbyist, or just starting your electronics journey, understanding these complexities is indispensable.

With the use of electricity all around us today, the global electric switch market size is expected to reach $23.8 billion by 2032. Therefore, we’ll help you understand normally open vs normally closed switches in detail, from their basic working principles to applications and much more.

Basic Principles of Switch Operation

Switches play a fundamental role in electronic circuits, serving as control devices that manage the flow of electric current. The basic principles of switch operation revolve around the interruption or completion of an electrical path.

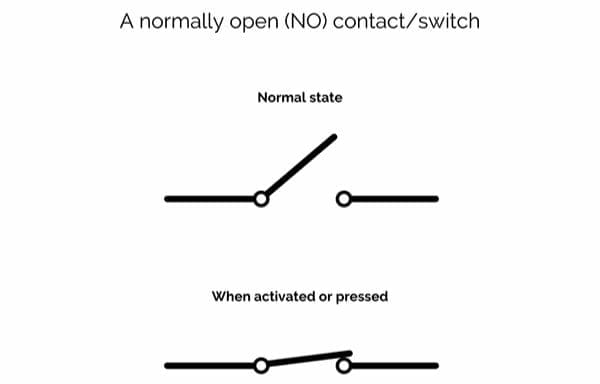

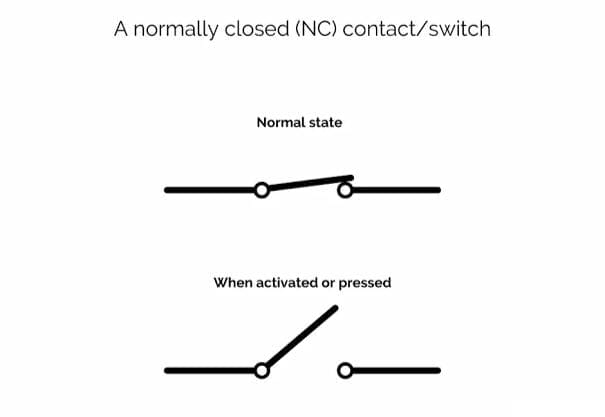

At its core, a switch consists of two primary states: normally open vs normally closed switch. In the open state, the switch prevents the current flow, creating a circuit gap. Conversely, in the closed state, the switch allows current to pass through, completing the circuit. This simple concept forms the foundation for various switch designs and applications.

Mechanical switches operate through toggling, which physically opens or closes metallic contacts. It alters the connectivity within the circuit, enabling or inhibiting the flow of electricity. However, mechanical switches may wear out over time due to the physical nature of their operation.

Modern electronic switches, such as transistors or solid-state relays, rely on semiconductor technology. They control the flow of current through the manipulation of electronic signals. For instance, applying a small voltage at the input terminal in transistors can control the larger current flowing between the output terminals.

Learn About Normally Open Switch

NO switches are used when it is important to detect a state change or control the electricity flow. They are often paired with normally closed switches to provide a complete control system.

For example, it can detect when a door or window is opened, triggering an alarm or other safety mechanism. Moreover, you can use it to turn lights on in various places and start or stop a motor in motor controls. Other applications of NO switches include temperature, fluid level, and pressure control.

- Prevent accidental activation by ensuring the circuit remains inactive until the operator wants otherwise.

- Offer precise circuit control, which is advantageous where specific timing or coordination is necessary.

- Prevent unnecessary current flow during idle periods, which can benefit battery-powered devices.

- Useful in simple push-button controls and more complex systems, providing flexibility in designing electronic circuits.

- Not suitable for applications that demand a high degree of safety.

- More prone to accidental activation.

Learn About Normally Closed Switch

These switches are commonly used in emergency stop buttons, safety interlocks, and door contacts. Moreover, they can also help monitor a system’s status, such as detecting the presence of a liquid in a tank. When the liquid level rises, the switch activates and sends a signal to the control system. Similarly, they can be used to control the operation of lights, fans, and other appliances.

- Normally closed switches are mostly used as safety devices and limit switches.

- They are useful where power needs to be cut off when the switch is activated.

- NC switches are less prone to accidental activation than NO switches.

- Normally closed switches require physical contact with the target.

- They are more prone to wear and tear than normally open switches.

Normally Open vs Normally Closed Switches – Key Considerations

Key Differences in Operation

When discussing normally open vs normally closed, it is important to understand that they differ fundamentally in their default states. A normally open switch remains open in its resting state, completing the circuit only when actuated. Conversely, a normally closed switch maintains a closed circuit at rest, breaking the circuit upon activation.

This contrast also results in different applications. Normally open switches are common in safety systems, requiring deliberate activation, while normally closed switches are used in scenarios where circuit interruption signals an abnormal condition.

Installation Considerations for NO Switches

Wiring Considerations

When installing a Normally Open (NO) switch, there are a few wiring things you should understand:

- Ensure that the power supply is turned off before beginning the installation process.

- Disconnect the wires that are connected to the existing switch.

- Connect the wires to the NO switch and attach them to the correct terminals.

- Finally, test the switch to ensure that it is working correctly.

It’s crucial to follow the manufacturer’s instructions and local electrical codes when installing NO switches.

Compatibility With Other Components

When installing NO switches, it is important to consider their compatibility with other components in the circuit, such as voltage and current ratings. Additionally, their contact material should be compatible to avoid corrosion and other issues. It is also important to ensure that their operating temperature range is compatible with other components in the circuit.

Installation Considerations for NC Switches

Safety Precautions

Here are some general guidelines to keep in mind while installing NC switches:

- Before inspecting a switch, be sure to turn OFF the power supply to the switch to avoid an electric shock. Same goes for mouting, demounting, and wiring.

- Don’t do wiring when power is being supplied to a switch.

- Select suitable switch ratings after confirming contact load. If it’s excessive, the contact may weld or shift, possibly resulting in burning or short circuits.

- Don’t use switches near combustible or explosive gasses.

- Avoid dropping or disassembling switches, as it might result in damage, electric shock, or burning.

Normally Open Vs Normally Closed Switches – Factors Influencing Choice

When it comes to normally open vs normally closed switches, it’s important to consider the environmental factors that can potentially affect their performance, such as temperature, humidity, and vibration.

For example, if it is going to be used in a high-temperature environment, choose a switch that can handle that without malfunctioning. Similarly, the switch must also resist moisture and corrosion in high humidity conditions. Vibration can also be a detrimental factor, as it can lead the switch to malfunctioning or premature failure.

By considering such factors, you can choose a switch that is best suited for your application and ensure reliable performance.

A discussion of normally open vs normally closed switches is incomplete without understanding circuit requirements. Here, it’s important to remind you that NO switches are open in their default state, while NC switches are closed.

An important consideration here is the application of normally open vs normally closed switches. NO switches are commonly used for start buttons, reset buttons, and light switches, while NC switches are used for safety and emergency stop buttons. In addition, the voltage and current rating of the switch are also crucial factors that shouldn’t be overlooked when determining circuit requirements.

There are several cost implications to consider when discussing normally open vs normally closed switches. NO switches are typically less expensive than their NC counterparts because the former are easier to manufacture. However, the cost of the switch shouldn’t be the only decisive element here.

The cost of installation and maintenance should also be taken into account. NC switches are often used in safety-critical applications where the switch must be closed to ensure foolproof safety. In these cases, it makes complete sense to spend a little more and secure a much more valuable system.

An important aspect of the normally open vs normally closed switches debate is safety.

NO switches are generally considered safer because they are less likely to get stuck in the closed position. However, they are also more prone to wear and tear because of their deployment in high-stress applications. On the other hand, NC switches face less wear and tear but are harder to maintain.

In terms of safety, NO switches are generally considered better because they can quickly break the circuit when activated. On the contrary, NC switches can be better designed to fail in the open position to prevent damage.

Future Trends

With the advent of the Internet of Things (IoT), switches have become smarter and more intuitive. Smart switches are now capable of being controlled remotely via a smartphone apps, voice commands, or even motion sensors. They can also be coupled with other smart home devices, such as security cameras, thermostats, and smart speakers.

In terms of design, electric switches have become more sleek and modern. There are now switches that can be customized to match the decor of your home. Some switches even come with built-in LED lights that can be programmed to change color or brightness based on your preferences.

The integration of IoT has also led to the development of switches that can monitor and control energy consumption. They can detect when a room is empty and automatically turn off/on the lights or adjust the temperature to save energy. Moreover, they can provide real-time data on energy usage, allowing people to make informed decisions about their energy consumption.

Conclusion

After reading this detailed guide on normally open vs normally closed switches, you are well aware of the aspects you may have missed before. However, the electrical market is full of choices, so which one should you buy?

The answer here is Langir, a reputable switch manufacturer with years of experience. We believe in innovation and quality, bringing our customers electrical equipment of the highest industrial standards. So, book your order today and step into a new era of electrical connectivity.

Send your inquiry now

All Langier News:

Read Moreelectronica 2024 Hall-Stand No.: A2 160 November 12-15, 2024 Tr...

English

English 简体中文

简体中文