Piezo switches have become increasingly popular in various industries due to their durability and responsiveness. However, ensuring their reliability is crucial, as they are often used in critical applications. In this article, we will delve into the reliability testing of piezo switches, understanding the procedures, and their significance in different industries.

What Is a Piezo Switch

Piezo switches are a type of switch that uses the piezoelectric effect to generate an electrical signal when pressure is applied. They are known for their robustness, making them suitable for harsh environments and high-demand applications. These switches are commonly used in industries such as aerospace, automotive, medical, and industrial automation.

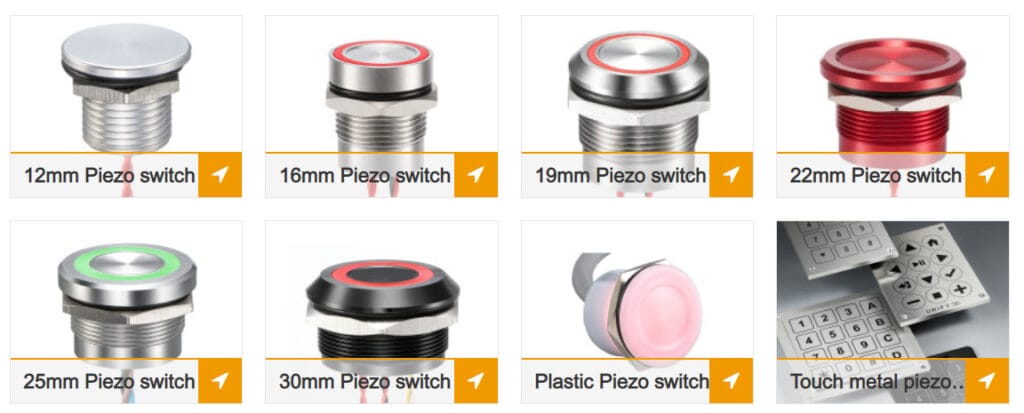

Types of Piezo Switches

There are two primary types of piezo switches: capacitive and resistive. Capacitive piezo switches are touch-sensitive and require no physical pressure, while resistive piezo switches require a physical push to actuate. Both types require reliability testing to ensure they perform as expected.

Common Failures in Piezo Switches

Some common failures in piezo switches include contact failure, sensitivity issues, and electrical malfunctions. These can lead to system failures and pose safety risks.

What Is a Reliability Test?

Reliability testing is a systematic evaluation of a product’s performance over time. It helps manufacturers identify potential weaknesses and areas for improvement. In the case of piezo switches, reliability testing ensures that they can withstand continuous use without failures.

Importance of Reliability Testing

Reliability testing is essential because it helps in:

- Ensuring Product Quality: Testing piezo switches for reliability ensures that only high-quality, dependable switches are used in critical applications.

- Cost Reduction: Identifying and rectifying issues during testing prevents costly recalls and replacements.

- Customer Satisfaction: Reliable products lead to satisfied customers who trust the brand.

The Need for Reliability Testing

Piezo switches often endure harsh conditions, including extreme temperatures, vibrations, and exposure to various chemicals. Reliability testing is essential to confirm that they can withstand these conditions without failure.

Reliability Testing Procedures

Reliability testing for piezo switches includes several key procedures:

Accelerated Life Testing

This testing involves subjecting the switches to extreme conditions for a shorter period to simulate long-term use. It helps identify potential weaknesses in the switches.

Environmental Testing

Testing in extreme environmental conditions, such as extreme heat, cold, or humidity, assesses the switches’ ability to function in harsh settings.

Vibration Testing

Vibration testing simulates the effects of constant movement or mechanical stress on the switches, making sure they can endure such conditions.

Thermal Cycling Testing

Switches undergo temperature variations to check their stability and reliability under extreme temperature changes.

Electrical Testing

This involves assessing the switches’ electrical performance, ensuring they meet the required specifications.

Case Studies

To emphasize the importance of reliability testing, let’s look at a few case studies where piezo switch failures could have had severe consequences.

Case Study 1: Aerospace Applications

In the aerospace industry, the reliability of components is paramount, given the extreme conditions aircraft encounter during flight. Piezo switches are commonly used in critical functions within the cockpit and various control systems. These switches must perform flawlessly under high altitudes, rapid temperature changes, and constant vibrations.

The Challenge

A leading aerospace manufacturer was incorporating piezo switches into their aircraft’s control panels. They needed to ensure that these switches could withstand the harsh environment of aviation without failure. Failure of a piezo switch during a flight could lead to catastrophic consequences.

The Solution

The manufacturer conducted comprehensive reliability testing on the piezo switches. They employed accelerated life testing, environmental testing, vibration testing, and thermal cycling testing to simulate the in-flight conditions. The switches were exposed to extreme temperatures, rapid pressure changes, and continuous vibrations to identify potential weaknesses.

The Result

Through rigorous reliability testing, the manufacturer identified a minor design flaw in the switches. This flaw was promptly rectified, ensuring that the piezo switches could withstand the demands of the aerospace environment. As a result, the aircraft’s control systems performed flawlessly, enhancing safety and reliability.

Case Study 2: Medical Devices

In the medical industry, reliability is a matter of life and death. Medical equipment, such as ventilators and defibrillators, relies on precise and dependable components to save lives. Piezo switches are used in these devices for their responsiveness and durability.

The Challenge

A medical equipment manufacturer was incorporating piezo switches into their ventilators. These devices needed to function reliably in high-stress situations, and any failure could have dire consequences for patients. Reliability was a top priority for the manufacturer.

The Solution

To ensure the reliability of piezo switches in medical devices, the manufacturer conducted extensive reliability testing. They focused on electrical testing and thermal cycling testing to evaluate the switches’ performance under high workload and temperature variations.

The Result

Reliability testing revealed that the piezo switches performed consistently under demanding conditions. They withstood continuous use without experiencing sensitivity issues or electrical malfunctions. As a result, the medical devices equipped with these switches provided dependable support to medical professionals and saved lives in critical situations.

In conclusion, these case studies underscore the critical role of reliability testing in ensuring the effectiveness of piezo switches in both aerospace and medical applications. Through rigorous testing procedures, manufacturers can identify and rectify any weaknesses, guaranteeing the reliability of these switches in high-demand and critical environments.

Conclusion

Reliability testing is the cornerstone of ensuring the effectiveness of piezo switches in critical applications. By subjecting these switches to various testing procedures, manufacturers can guarantee that they perform consistently and reliably in demanding conditions. Whether in aerospace, medical, automotive, or industrial applications, the reliability of piezo switches is paramount to success.

FAQs

1. Why are piezo switches used in critical applications?

Piezo switches are preferred for their durability and responsiveness, making them suitable for applications where reliability is crucial.

2. What is accelerated life testing, and why is it important for piezo switches?

Accelerated life testing involves subjecting switches to extreme conditions briefly to simulate long-term use, helping identify potential weaknesses in the switches.

3. What types of piezo switches require reliability testing?

Both capacitive and resistive piezo switches require reliability testing to ensure their performance in different applications.

4. What are some common failures in piezo switches?

Common failures include contact failure, sensitivity issues, and electrical malfunctions, which can lead to system failures and safety risks.

5. How does reliability testing benefit manufacturers and customers?

Reliability testing ensures product quality, reduces costs, and enhances customer satisfaction by providing reliable products that instill trust in the brand.

Send your inquiry now

All Langier News:

Read Moreelectronica 2024 Hall-Stand No.: A2 160 November 12-15, 2024 Tr...

English

English 简体中文

简体中文