Capacitive switch technology operates without mechanical movement, sensing touch via electrical field alterations to deliver exceptional durability and responsiveness. This comprehensive guide will explore the core principles of capacitive switches, their distinctions from conventional mechanical counterparts, key advantages and considerations, and their optimal applications within industrial environments. We will also detail Langir’s robust customization and bulk-supply solutions for our manufacturing partners, alongside addressing critical aspects such as operational lifespan, user feedback, and performance in challenging conditions.

Understanding Capacitive Switches: Core Principles and Operation

A capacitive switch functions as a solid-state human-machine interface (HMI) component, detecting touch by measuring alterations in electrical charge to activate or deactivate a circuit. This touch-sensing mechanism leverages an electrostatic field, eliminating the need for moving parts and rendering the switch highly resistant to mechanical wear. For instance, the proximity of a conductive object, such as a finger, to the button surface causes the switch’s integrated electrodes to register a capacitance shift, initiating the intended command.

Get a quote for custom capacitive switches from Langir

The Principle of Capacitance in Solid-State Switching

Capacitance defines the capacity of two conductive elements to accumulate and store an electrical charge. Within a capacitive switch, a precisely engineered pair of electrodes establishes a miniature capacitor. When a conductive entity approaches the sensor surface, it effectively augments the local capacitance by integrating its own conductive properties into the system. This minute change is meticulously measured by a dedicated sensing circuit and subsequently translated into a switch activation, ensuring exceptional sensitivity and precise control with every interaction.

Non-Mechanical Touch Detection: The Capacitive Advantage

Capacitive switches continuously project a low-voltage signal, generating a stable electrostatic field around the sensor pad. When a conductive object, such as a finger or specialized stylus, disrupts this field, the integrated circuit precisely registers the resulting change in capacitance. A dedicated microcontroller subsequently processes this signal, transmitting the command to the output device, thereby enabling a tactile-free operational experience devoid of springs, plungers, or traditional metal contacts.

Key Components of a Capacitive Switch

A typical capacitive switch consists of:

- A precisely patterned electrode layer, typically etched onto a printed circuit board (PCB) or a flexible substrate.

- A high-performance sensing integrated circuit (IC) engineered to meticulously monitor capacitance variations.

- A robust insulating overlay, often crafted from glass, plastic, or metal, providing both critical protection and enhanced aesthetics.

- Optional integrated LED backlighting for clear status indication.

These meticulously engineered layers are bonded into a fully sealed assembly, effectively preventing dust ingress and facilitating effortless cleaning. This inherent sealed architecture is a primary factor in why capacitive switches consistently outperform traditional mechanical designs in demanding industrial environments.

Capacitive vs. Mechanical Switches: A Comparative Analysis

While both capacitive and mechanical switches fulfill the fundamental role of circuit control, their operational principles, lifespan, and user interaction experiences diverge significantly. A thorough understanding of these critical distinctions empowers industrial engineers to select the optimal interface component for applications spanning automation, medical instrumentation, and advanced control panels.

Get a quote for custom capacitive switches from Langir

Operational Disparities: Capacitive vs. Mechanical

Capacitive switches function by detecting subtle changes in an electrical field, whereas mechanical switches rely on physical movement and the direct engagement of metal contacts to establish or interrupt a circuit. This fundamental difference grants solid-state capacitive buttons superior response times and eliminates contact bounce, a common issue with mechanical designs that depend on springs and actuators for a distinct tactile click.

Durability and Lifespan: A Direct Comparison

Capacitive switches are engineered for exceptional longevity, typically enduring up to 50 million activations due to their non-mechanical, solid-state design. In contrast, mechanical switches frequently exhibit wear-out after 1–5 million cycles, primarily due to metal fatigue and susceptibility to contamination. This significant disparity in operational lifespan is a key factor driving the widespread adoption of capacitive buttons in high-demand industrial environments where uninterrupted uptime is paramount.

Capacitive Switch Durability and Extended Lifespan

Capacitive switches are renowned for their unparalleled durability, attributed to their inherent lack of moving components, which translates into an operational lifespan extending up to 50 million cycles. This stands in stark contrast to mechanical switches, which commonly experience failure after 1–5 million cycles due to cumulative wear and tear [1, 6, 14, 19].

Capacitive Touch Switch: Operation and Functionality (2024)

This reference substantiates the superior operational lifespan of capacitive switches compared to their mechanical counterparts.

Activation Force and Tactile Feedback: Key Distinctions

The activation force required for capacitive switches is remarkably low—frequently less than 5 grams—enabling effortless touch operation. Conversely, mechanical buttons typically demand 50–100 grams or more, delivering a distinct tactile “click.” While certain operators may prefer this physical feedback, advanced capacitive designs can effectively simulate click sensations through integrated haptic modules or audible tones, all without impacting their inherent extended lifespan.

Environmental Resilience: Capacitive vs. Mechanical

Capacitive switches feature a fully sealed construction, providing comprehensive protection against dust, moisture, and corrosive chemicals, frequently achieving IP67/IP68 and IK08 ratings. In contrast, mechanical switches possess inherent gaps around their moving components, allowing ingress that compromises reliability in harsh or wash-down environments. This robust, sealed architecture positions capacitive buttons as the optimal choice for demanding applications such as food processing, outdoor kiosks, and chemical manufacturing facilities.

Capacitive Switch Environmental Robustness

Capacitive switches are exceptionally well-suited for deployment in challenging environments due to their hermetically sealed construction, which provides superior protection against dust, moisture, and aggressive chemicals. They consistently achieve high ingress protection ratings, often up to IP67/IP68, and impact resistance up to IK08, rendering them ideal for critical applications such as food processing and outdoor public interfaces [4, 5, 6, 9, 10, 13, 15].

Niceone-Keypad Solutions (2024)

This reference validates the suitability of capacitive switches for deployment in demanding environmental conditions.

Key Advantages of Capacitive Over Mechanical Switches

Capacitive switches offer benefits extending far beyond their extended operational lifespan; they significantly enhance productivity, minimize maintenance requirements, and elevate operator comfort across a spectrum of demanding industrial applications.

Get a quote for custom capacitive switches from Langir

Enhanced Durability and Reliability of Capacitive Switches

Devoid of wear-prone springs or physical contacts, capacitive switches consistently deliver stable performance across tens of millions of operations. Their inherent solid-state design effectively eliminates contact bounce and degradation, guaranteeing precise and reliable actuation in high-cycle or high-speed machinery control systems.

Minimizing Maintenance and Downtime with Capacitive Switches

Their fully sealed construction actively prevents the accumulation of dust and the onset of corrosion, thereby reducing cleaning frequencies and mitigating the risk of unforeseen failures. The combined benefits of reduced hardware replacement and simplified enclosure designs directly translate into substantial reductions in operational expenditures and fewer service interventions.

Capacitive Switches: Engineered for Harsh Industrial Conditions

Superior chemical resistance, full wash-down capability, and robust IP-rated protection collectively safeguard against moisture, industrial oils, and particulate contamination. This enables seamless integration of capacitive panels into demanding environments such as industrial food-processing lines or petrochemical facilities, eliminating the need for supplementary protective boots or covers.

Optimizing User Comfort and Productivity with Low Activation Force

The minimal touch pressure required significantly reduces operator finger fatigue in high-volume operational settings, including packaging lines and assembly station controls. Operators experience enhanced productivity through faster cycle times and reduced physical strain, directly contributing to ergonomic workplace design and superior quality output.

Capacitive Switches: Addressing Limitations and Considerations

Despite their numerous advantages, capacitive switches do present certain considerations, particularly concerning user feedback and specific application scenarios.

Tactile Feedback: A Key Distinction

Inherently, capacitive switches do not provide a physical click sensation. To address this, manufacturers frequently integrate haptic motors, audible beepers, or visual illuminated feedback to simulate a responsive user experience. While effective, these supplementary solutions introduce additional cost and design complexity.

Performance with Gloves and Non-Conductive Materials

The touch sensitivity of capacitive switches is contingent upon the detection of a conductive medium. Consequently, thick or non-conductive gloves can attenuate the capacitance change, necessitating precise calibration or the use of specialized overlay materials to ensure consistent responsiveness. In contrast, mechanical switches operate independently of the conductivity of the activating object.

Cost Analysis: Capacitive vs. Mechanical Switches

While capacitive switch modules and their integrated sensing ICs typically present a higher initial unit cost compared to basic mechanical buttons, a comprehensive total cost of ownership (TCO) analysis often demonstrates the economic advantage of capacitive solutions. This is particularly true at scale, considering factors such as significantly reduced maintenance, extended operational lifespan, and simplified enclosure sealing requirements.

Industrial Applications of Capacitive Switches

Solid-state touch buttons demonstrate superior performance in environments where durability, stringent hygiene, and unwavering reliability are paramount.

Get a quote for custom capacitive switches from Langir

Capacitive Switches in Human-Machine Interfaces (HMIs) and Control Panels

Capacitive panels integrate seamlessly into advanced industrial Human-Machine Interfaces (HMIs), providing intuitive operation and consistent, reliable performance across manufacturing lines. Their expansive, flat overlay designs facilitate the incorporation of sophisticated graphical icons and flexible layouts, eliminating the need for multiple cutouts typically required for mechanical actuators.

Capacitive Switches: The Preferred Choice for Medical Equipment

Sterile medical environments necessitate fully sealed interfaces capable of withstanding frequent and rigorous cleaning with disinfectants. Capacitive switches inherently support these stringent hygiene standards by eliminating the crevices and gaps where contaminants could otherwise accumulate.

Enhancing Automotive and Vending Machine Interfaces with Capacitive Technology

Automotive dashboards increasingly utilize capacitive buttons to achieve sleek, backlit control surfaces, thereby minimizing interior clutter and enhancing aesthetic appeal. Vending machines, deployed in high-traffic public locations, benefit immensely from the virtually unlimited operational lifespan of capacitive switches, significantly reducing service interventions and ensuring maximum uptime.

Capacitive Switches: Optimal for Harsh and Dusty Environments

Their superior IP ratings and robust chemical-resistant overlays ensure continuous sensor operation even in the presence of dust, oils, or high humidity. Industries spanning from mining operations to food processing facilities depend on capacitive push buttons to maintain unwavering performance under conditions of extreme environmental exposure.

Langir: Customization and Supply Solutions for Industrial Capacitive Switches

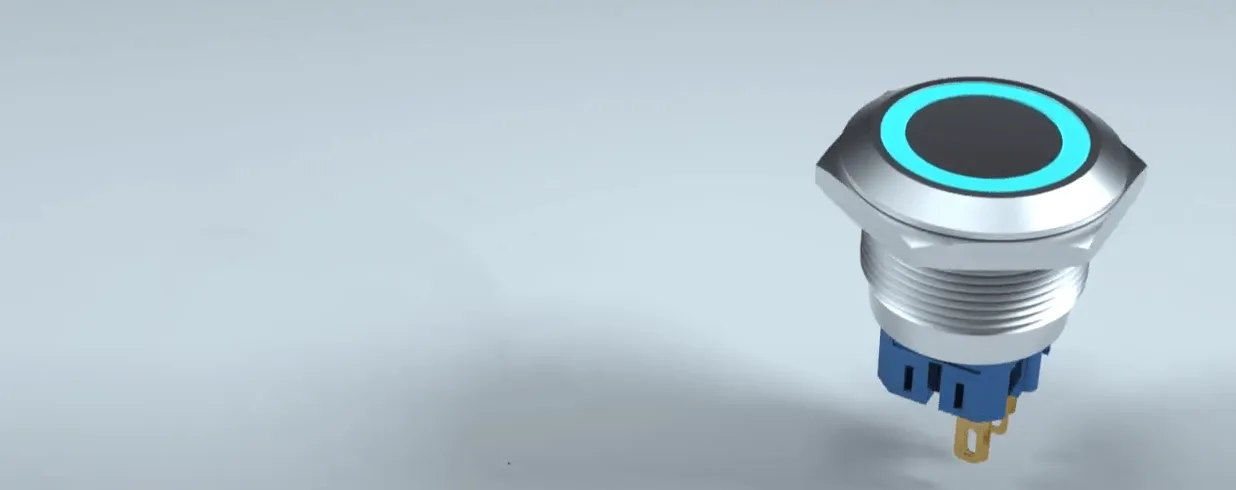

Langir’s CP Series capacitive switches exemplify a fusion of robust engineering, flexible customization capabilities, and efficient bulk supply options, meticulously tailored to meet the precise requirements of our manufacturing clientele.

Get a quote for custom capacitive switches from Langir

Langir Capacitive Switches: Comprehensive Customization Options

Langir provides an extensive range of customization options, including diameters from 16 mm to 25 mm, diverse housing materials such as high-grade stainless steel, durable plastic, and resilient glass, alongside full-color LED backlighting. Our bespoke graphic overlays and precision-engineered mounting styles guarantee seamless integration into any sophisticated control panel design.

Langir Capacitive Switch Customization Capabilities

Langir provides a comprehensive suite of customization options for our capacitive switches, encompassing a range of diameters, premium housing materials, advanced LED backlighting, and bespoke graphic overlays. These extensive options ensure flawless integration into diverse control panel configurations [8, 10, 12].

Langir Product Portfolio (2025)

This reference confirms Langir’s extensive customization capabilities for capacitive switch solutions.

Streamlined Bulk Ordering for Industrial Manufacturers

Langir’s advanced production lines are engineered to efficiently scale and accommodate high-volume demands, with lead times meticulously optimized for recurring orders. Our competitive volume pricing and comprehensive logistics support empower industrial manufacturers to procure hundreds or thousands of switches without encountering inventory bottlenecks. For a detailed bulk quote on capacitive switches, please navigate to our Contact Us page.

Why Langir is Your Partner for Robust Capacitive Switch Solutions

Langir’s unparalleled expertise in solid-state push button technology guarantees stringent quality control, superior IP-rated sealing, and exceptional IK impact resistance. Our collaborative approach with industrial partners fosters continuous innovation, delivering precisely tailored reliability across every demanding application.

Capacitive vs. Mechanical Switches

Presented below is a concise overview addressing the most common inquiries from industrial buyers when evaluating these distinct switch technologies.

This comparative analysis underscores the superior performance of capacitive switches in terms of operational cycle life and minimal activation force, providing crucial guidance for selection within industrial automation applications.

These practical examples clearly illustrate why capacitive switches are increasingly displacing mechanical counterparts in highly demanding industrial and consumer applications.

Conclusion

Capacitive switches fundamentally differ from mechanical devices; their operation hinges on detecting capacitance changes rather than physical contact movement, endowing them with superior durability and exceptionally low activation force. While traditional mechanical switches retain their appeal for tactile feedback and straightforward implementation, capacitive designs offer unparalleled sealed protection, significantly reduced maintenance requirements, and extended operational lifespans reaching up to 50 million cycles. Industrial manufacturers gain a distinct advantage through Langir’s CP Series, benefiting from extensive custom options, optimized bulk-supply efficiencies, and rigorous quality control protocols. We encourage you to embrace capacitive technology to streamline your control panels, substantially reduce operational downtime, and elevate operator comfort with a truly future-proof interface solution.

EN

EN