Ever thought about how to bypass your car horn switch without hassle? This blog post lays out key steps—from dialing in safety measures with the right tools to setting up a temporary horn bypass at the relay. Readers will gain clear guidance on establishing a new horn connection wiring that actually works. The content provides simple instructions to solve common pain points, making those horn system issues a thing of the past.

Reasons for a Car Horn Switch Bypass

Car horn issues can be tricky. Experts check signs of a failing horn switch, test the original car horn button, locate the horn relay and fuses, and tell a switch glitch from a wire fault. They also know when a bypass is needed, like using a french horn bypass method posted on the internet. Even a loose tire on details matters.

Contact Langir for Custom Car Horn Switches

Recognizing Signs of a Failing Horn Switch

The expert identifies issues by checking if the horn button, on the steering wheel, trips correctly; a failing switch might stop your horn from sounding when you need it most—think of it like a glitch in javascript code causing a crash during shipping of a new motorcycle order:

- Test the horn push button

- Inspect the wiring connection using a wire stripper

- Assess the reliability of the steering wheel integration

- Review any inconsistencies similar to a faulty javascript execution

Testing the Original Car Horn Button Functionality

The expert notes that checking for proper voltage across the horn circuit is key, making sure the horn clicks with a true pulse not unlike a well-oiled valve in action. In the United Kingdom and beyond, real hands-on testing shows whether the original horn button works as designed, and if not, it’s a signal to contact Langir for a durable fix.

Locating the Horn Relay and Related Fuses

The expert finds the horn relay and related fuses with the precision of someone handling electronics and machinery—like fixing up quality equipment or a cherished piece of furniture. They use a sharp eye and quick checks for proper power flow, much like ensuring a boat’s motor runs smooth and clean when it matters most.

Differentiating Switch Problems From Wiring Faults

The expert clarifies that a problematic horn can come from either the switch or the wiring, so he uses a multimeter to test the circuit’s power supply. He treats the car like a well-run cart, noting that even in markets like France, pinpointing a fault—be it in the switch or elsewhere—brings a bit of entertainment to troubleshooting and smart fixes.

Assessing When a Horn Bypass Becomes Necessary

The expert notes that a horn bypass is considered when repeated issues occur with the airbag system’s communication, or when the button on a golf cart or car fails to transmit the expected ampere, signaling deeper electrical problems. This clear sign of malfunction prompts a rewire where safety and reliability take center stage:

Safety Measures and Tools for Horn System Work

Disconnect the battery first. Use proper hand tools to access the horn components. Gather wires, connectors, and a multimeter to check circuits, just like a dependable relay or lever. Personal protective gear is a must. These tips blend customer service care with the ease of riding a bus and the rhythm of music for safe, smart work.

Contact Langir for Custom Car Horn Switches

Disconnecting the Vehicle Battery Before Starting

Before working on the horn system, disconnecting the vehicle battery is a must—nobody wants unexpected sparks while handling intricate parts like a slip ring or brush, and a sudden surge can turn a simple packaging job into a noisy mess, much like a misbehaving musical instrument; experts stress this step to cut off any risk before moving forward:

- Ensure the battery terminals are safely removed

- Double-check that all tools are properly isolated

- Have your safety gear ready for a smooth process

Required Hand Tools for Accessing Horn Components

The expert selects the right hand tools for accessing horn components, opting for trusted electrical gear that ensures safety while keeping the ignition system running smoothly. Using quality tools feels like switching train tracks, making sure every vehicle, whether in Africa or anywhere else, operates with a dependable rhythm.

Selecting Appropriate Wires and Connectors

The expert selects wires and connectors that stand up to tough use and deliver solid feedback, choosing quality gear made with brass for a secure connection—knowledge gained from years of hands-on work in Canada and beyond pays off when safety is key:

- Sturdy, insulated wires

- Reliable brass connectors

- Tools that ensure tight fittings

- Components that meet industry standards

Using a Multimeter for Circuit Testing

The expert uses a multimeter to check voltage levels in the circuit, ensuring everything from the train horn to steel connectors is in proper working order under steady lighting for easier maintenance:

- Disconnect the battery for safety

- Test voltage across the horn switch

- Inspect wiring conditions

- Confirm proper functionality with reliable readings

Personal Protective Equipment Recommendations

The expert advises always suiting up with solid protective gear like gloves and safety glasses when working on a car horn switch, much like ensuring a reliable pump is in use. Every detail counts, whether dealing with a tight price on quality tools or handling stainless steel parts, and even someone in portugal would know that keeping attention on safety is key. This honest, hands-on tip links practical know-how with a straightforward approach that every mechanic can trust.

Performing a Temporary Horn Bypass at the Relay

This section explains accessing the horn relay. It covers mapping relay socket terminals, crafting a jumper wire with plastic connectors, and testing with meter equipment. Troubleshooting a direct activation follows, all in line with the national electrical code. Italy-based tips add practical insight, ensuring that the temporary connection works effectively.

Contact Langir for Custom Car Horn Switches

Gaining Access to the Horn Relay Location

Finding the horn relay is as straightforward as tuning a saxophone—start by checking near the steering column and work your way through the accessible fuse panel where signals travel like electrons. The process might feel as surprising as a turkey at a headlamp festival, yet careful inspection reveals a clear path to the relay, making temporary bypass work like a charm for those in need of swift fixes.

Mapping the Relay Socket Terminals

The expert maps the relay socket terminals with the care of someone setting up a custom car horn switch, ensuring that each crimp and screw is in the right place to keep the electricity flowing smoothly—whether on the road or in the shop. This approach saves time and hassle when issues arise, making temporary fixes a lot less nerve-wracking.

Crafting a Jumper Wire for the Horn Bypass

The expert crafts a jumper wire with care, ensuring the new connection works as a temporary fix for a truck’s horn failure, using a setup that any customer can appreciate—almost like a french trick on the steering system. This repair method is straightforward and reliable, offering a quick solution for those who need their horn back in action. The process, honed through years of hands-on work, stands as proof that smart fixes can be both simple and effective.

Activating the Horn Directly Through the Relay Socket

The expert activates the horn directly through the relay socket using a solid electrical connector to bring an air horn backup online for retail customers who need to continue using their vehicle without delay, keeping the wheel steady and the fix simple and quick:

Verifying the Temporary Horn Connection Works

The expert verifies the temporary horn connection by checking that all signals appear as expected, much like scanning a posted menu for hidden gems. The sound pulse travels through a metal pathway with precision reminiscent of Milbank’s exacting standards, ensuring no stray interference disrupts the brake system’s role. This step makes sure the bypass not only works but holds steady until a permanent fix can be made.

Guide to Car Horn Button Installation as a Bypass

Start by picking a momentary car horn button switch to control your vehicle horn. Next, find a good mount spot and plan the wire route from the relay to the switch, much like checking your web browser for the latest shop offers in south africa. Prepare your mounting spot and ensure the solenoid setup is spot-on for reliable performance.

Contact Langir for Custom Car Horn Switches

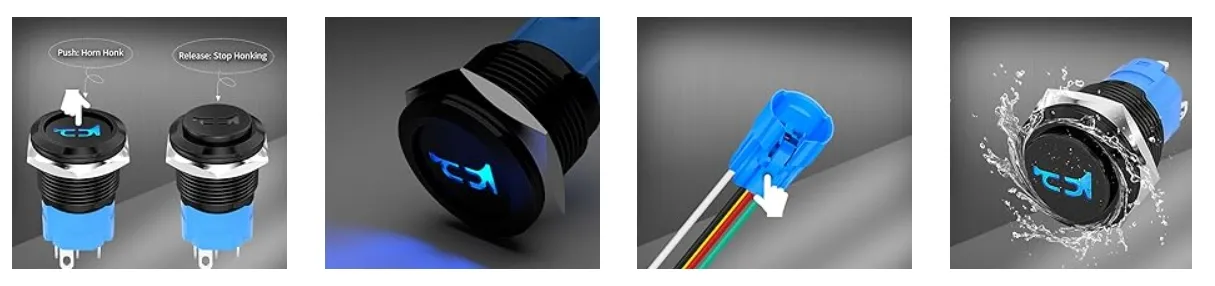

Selecting a Suitable Momentary Car Horn Button Switch

The expert selects a good momentary car horn button switch that fits well on the dashboard and syncs smoothly with the fuse setup, ensuring the bypass installation remains neat and practical. The choice involves matching the button’s size and durability with the vehicle’s requirements before proceeding with the following steps:

- Review the switch’s compatibility with the dashboard layout

- Check that the fuse can handle the new wiring load

- Test for responsive feedback during continuous use

Determining an Accessible Mounting Location for the New Button

The expert finds a spot where the new horn button is both easy to reach and securely mounted, ensuring no fiddling needed during use. The choice of location minimizes wiring hassle and fits the vehicle’s design, offering a smart and functional fix for bypassing the car horn switch. This clear, hands-on approach makes it a practical upgrade for reliable performance.

Planning the Wire Route From Relay to Switch

Planning the wire route from the relay to the switch involves a clear layout to avoid unnecessary clutter and ensure efficient current flow. The expert maps out a simple, reliable pathway with the right connectors and quality wires to minimize interference and keep the car horn switch bypass running smooth and steady:

Drilling or Preparing the Mounting Spot

The expert preps the mounting spot with steady hands and a clear set of instructions—a quick drill here, a precise mark there—to ensure the new horn button finds its rightful, secure place. The process is straightforward and practical, cutting out any guesswork while keeping the installation neat and effective for a quick bypass setup.

Establishing the New Horn Connection Wiring

Tapping into the horn relay’s power output, running wire to the new car horn button switch input, connecting the switch output to the horn circuit, securing a reliable ground, and insulating connections are key steps. Each topic explains a simple, practical fix for bypassing your car horn switch, ensuring a safe and efficient setup.

Contact Langir for Custom Car Horn Switches

Tapping Into the Horn Relay’s Power Output Wire

The expert taps into the horn relay’s power output wire by isolating the correct lead and confirming steady voltage with a reliable meter, ensuring the new connection works right away:

Running Wire to the New Car Horn Button Switch Input

The expert runs the wire to the new car horn button switch input with steady precision, ensuring a no-nonsense connection that meets high standards for safety and reliability. This step requires careful routing through the vehicle’s interior, keeping the setup clean and functional so that the modified horn system works just as it should. The approach is straightforward and clearly designed to give bulk buyers the confidence they need in their car horn switch bypass solution.

Connecting the Switch Output to the Horn Circuit

The expert connects the switch output to the horn circuit by firmly attaching the wires, ensuring a reliable push of current so your horn sings when needed. This firm connection makes bypassing the car horn switch a breeze, saving time and avoiding frustration during repairs. Reliable wiring means fewer headaches and a smoother ride for bulk buyers seeking an efficient fix.

Securing a Proper Ground Point for the New Switch

The expert makes sure the new switch finds a solid ground by checking the connection carefully. Using a multimeter, the expert confirms a steady flow to keep the car horn switch bypass efficient and reliable.

Insulating All New Electrical Connections

Langir’s expert ensures every new electrical connection gets proper insulation to ward off shocks and prevent shorts; the expert checks that high-quality insulation wraps snugly around every splice, keeping the wiring safe and efficient:

Testing and Finalizing Your Horn Bypass Setup

Reconnect the vehicle battery safely, then test the new button installation to ensure your horn responds as expected. Check for wiring faults and troubleshooting common issues, while recognizing if your fix is just temporary or built to last. Finally, know when to call a professional auto electrician to keep things running smoothly.

Contact Langir for Custom Car Horn Switches

Reconnecting the Vehicle Battery Safely

After setting up the horn bypass, experts reconnect the battery with a calm, deliberate approach to make sure everything works as it should. They advise checking each connection with a reliable meter so the car horn switch kicks in safely when needed.

Activating the Horn Using the New Button Installation

The expert activates the horn using the new button installation by pressing the switch and checking the immediate response, ensuring that the bypass setup delivers a solid tone every time. The process is straightforward and tested with hands-on reliability, which involves these steps:

- Reconnect the battery safely

- Test the voltage at the new button

- Inspect all connections for a secure flow

- Confirm the horn sounds consistently

Troubleshooting Common Issues With the Horn Bypass

The expert notes that when a horn bypass doesn’t work, it’s usually due to loose connections or overlooked wiring faults, so checking all connections with a multimeter can reveal what’s amiss. The expert emphasizes a calm, step-by-step approach to ensuring every part of the circuit delivers steady electricity, making it easier to identify and fix any hiccups along the way.

Understanding the Permanence of Your Solution

The expert notes that while a bypass may restore the horn quickly, it might not replace a permanent repair. A solid check on voltage and wiring reveals if the fix can stand up to everyday use or if further work is needed, ensuring bulk buyers and workshop pros get dependable results every time.

Knowing When Professional Auto Electrician Help Is Required

When the horn bypass setup still won’t deliver a strong signal or misbehaves despite a full recheck, the professional auto electrician steps in as the expert fix. Such situations call for hands-on troubleshooting with proper instruments and years of know-how, making sure every connection works safely and consistently, especially when bulk buyers need a sturdy, dependable solution.

How to Bypass Car Horn Switch | FAQs

What is a car horn switch bypass?

A car horn switch bypass is a workaround that reroutes the wiring to activate the horn without using the faulty switch, ensuring the car still sounds off when needed during repairs or modifications.

Which safety tools do I need for horn work?

For safe horn work, gear up with safety glasses, ear defenders, gloves, and a face mask. If using tools, secure a sturdy helmet and non-slip shoes to keep every step in check and mind at ease.

How do I perform a relay horn bypass?

Disconnect the relay from the horn circuit and reroute its signal directly through a bypass module. Check every connection to ensure safety and reliability.

Can a horn button installation serve as a bypass?

No, a horn button setup isn’t meant to cut out the wiring. It strictly triggers the push button switch and won’t bypass your system’s safety or design features. Stick with proper installation for reliable performance.

How do I test the new horn wiring connection?

Connect the horn wiring to a battery, then press the switch. Listen closely for a clear, stable sound. Verify all wiring is secure to ensure optimal performance and reliability before your final installation.

EN

EN