Capacitive switches flawlessly detect touch through robust non-conductive overlays like acrylic, leveraging changes in capacitance across a dielectric layer to ensure seamless, sealed interfaces for demanding industrial settings. In this guide, you’ll discover the mechanics of capacitive sensing through acrylic, optimal material specifications, effective electrode design strategies, key industrial applications, common troubleshooting tactics, and Langir’s bespoke customization and bulk-order solutions. We will cover:

- The fundamental interaction between electric fields and acrylic panels

- Ideal acrylic thickness, dielectric properties, and environmental considerations

- Electrode layout, spacing, and shielding best practices

- Key industries benefiting from acrylic-protected capacitive switches

- Common integration challenges and their resolutions

- Langir’s tailored design and streamlined ordering process

This comprehensive roadmap equips designers and procurement teams in industrial manufacturing with everything necessary to effectively deploy capacitive switches behind acrylic.

How Do Capacitive Switches Function Through Acrylic Panels?

Capacitive switches positioned behind acrylic panels detect finger proximity by generating an electric field that couples through the acrylic’s dielectric, registers a precise capacitance change, and triggers a logic output—enabling sealed, wear-free interfaces with unwavering performance.

Get a quote for custom capacitive switches from Langir

Understanding Capacitive Sensing: Principles and Operation

Capacitive sensing precisely measures the change in stored charge between an electrode and a reference ground when a conductive object (such as a finger) approaches. The sensor applies a low-voltage oscillating signal; as capacitance increases, an integrated controller converts this variation into a touch event. This mechanism supports rapid, contactless detection and significantly enhances durability in industrial controls, leading us to examine how acrylic’s dielectric properties influence this process.

How Does Acrylic’s Dielectric Constant Impact Capacitive Sensing?

Acrylic’s dielectric constant (typically 2.6–3.4) directly influences the baseline capacitance between the sensor electrode and a finger. Materials with a higher dielectric constant concentrate electric field lines more effectively, significantly boosting sensitivity through the barrier. Maintaining a consistent dielectric layer ensures stable detection thresholds and prevents drift over time, which paves the way to consider how thickness interacts with this critical property.

Dielectric Properties of Acrylic Explained

Acrylic’s dielectric constant, generally ranging from 2.6 to 3.4, dictates its capacity to concentrate electric fields, a crucial factor for effective capacitive sensing. This property directly influences the switch’s sensitivity and its interaction with a finger or other conductive objects.

Brandrup, J., & Immergut, E. H. (Eds.). Polymer Handbook (1999)

This authoritative source offers a general reference for the dielectric properties of various polymers, including acrylic, substantiating the article’s discussion of material characteristics.

What Role Does Acrylic Thickness Play in Switch Performance?

Acrylic thickness determines the distance the electric field must traverse before coupling with the finger. Thinner panels (2–5 mm) yield stronger capacitance changes and faster response, while thicker barriers necessitate higher sensor gain or wider electrodes. Balancing thickness ensures both robust mechanical protection and reliable activation, setting up the technical explanation of electric field propagation.

Acrylic Thickness and Capacitive Sensing Performance

The thickness of the acrylic panel directly impacts the performance of capacitive switches. Thinner panels generally result in stronger capacitance changes and faster response times, whereas thicker panels may require adjustments to sensor gain or electrode design for optimal operation.

Harper, C. A. Handbook of Plastics, Elastomers, and Composites (2002)

This comprehensive handbook provides essential information on the properties of plastics, including acrylic, and how these properties influence their application in various fields, such as capacitive sensing.

How Do Electric Fields Propagate Through Acrylic in Capacitive Switches?

Electric fields emanate from the electrode, fringe through the acrylic dielectric, and return via the finger or a ground plane beneath. Finite-element analysis demonstrates that field intensity decays with the square of the distance, so precise electrode geometry and sensor tune-up are critical to optimize field lines for maximal coupling. Understanding this field behavior is fundamental for both material selection and sensor calibration.

Optimizing Acrylic Thickness and Material Properties for Capacitive Switch Compatibility

Selecting the correct acrylic grade and thickness ensures consistent capacitance variation, reliable switching, and minimal false triggers under diverse operating conditions.

Get a quote for custom capacitive switches from Langir

What Is the Recommended Thickness Range for Acrylic in Capacitive Touch Applications?

Optimal acrylic thickness strikes a balance between mechanical strength and sensing performance. Typical guidelines for industrial capacitive switches are:

Panels within these ranges consistently deliver clear capacitance shifts and robust activation. Next, we’ll examine how environmental factors like moisture and temperature can alter these critical parameters.

How Do Moisture and Temperature Influence Acrylic’s Performance with Capacitive Switches?

Acrylic can absorb small amounts of moisture (0.2–0.4%) and expand slightly in high-humidity or extreme temperature conditions. This subtly alters its dielectric constant and thickness by fractions of a millimeter, potentially causing sensitivity drift. Proper sensor firmware with auto-tuning capabilities effectively counters these effects, maintaining stable switching thresholds across all operating environments.

Acrylic vs. Other Non-Conductive Materials: A Comparative Analysis

Acrylic, glass, and polycarbonate each offer distinct balances of clarity, impact resistance, and dielectric properties, making them suitable for different applications:

Advantages and Limitations: Acrylic vs. Glass for Capacitive Sensing

Acrylic provides lightweight, cost-effective panels that resist shattering, whereas glass offers superior dielectric stability but at increased weight and a higher risk of breakage. Designers typically select acrylic when mechanical safety, customization flexibility, and visual aesthetics are prioritized over the marginal sensing performance gain offered by glass.

Optimizing Electrode Design for Capacitive Switches Behind Acrylic Panels

Precisely optimized electrode layouts ensure sufficient electric field penetration through acrylic, accurate touch localization, and robust immunity to environmental noise.

Get a quote for custom capacitive switches from Langir

Which Electrode Layouts Enhance Sensitivity Through Acrylic?

Well-engineered electrode shapes, such as concentric rings or interdigitated patterns, distribute electric field lines uniformly under the touch area. Symmetrical layouts minimize dead zones and support consistent activation, even when acrylic thickness exhibits slight variations.

How Do Electrode Size and Spacing Influence Detection Accuracy?

Larger electrode areas increase baseline capacitance and sensitivity, while tighter spacing between digitated fingers raises field density. Typical recommendations include finger widths of 1–2 mm and spacing of 0.5–1 mm—parameters that consistently deliver reliable detection through up to 6 mm of acrylic.

Grounding and Shielding Techniques for Enhanced Performance with Acrylic

Floating shields and driven-shield electrodes strategically placed around the sensing area prevent stray fields and environmental interference. Ground planes positioned behind the acrylic stabilize the reference potential, significantly reducing false triggers in electrically noisy industrial environments.

Industrial Applications Benefiting from Capacitive Switches with Acrylic Interfaces

Sealed capacitive switches integrated behind acrylic panels excel in applications demanding exceptional durability, stringent hygiene, and superior vandal resistance.

Get a quote for custom capacitive switches from Langir

Industries Commonly Utilizing Acrylic Panels with Capacitive Switches

- Food processing machinery requiring rigorous wash-down safety protocols

- Medical equipment where sanitized, sealed surfaces are critical for contamination control

- Public kiosks and ticketing terminals exposed to harsh weather and dust

These sectors critically rely on sealed, abrasion-resistant controls that maintain unwavering responsiveness through protective acrylic overlays.

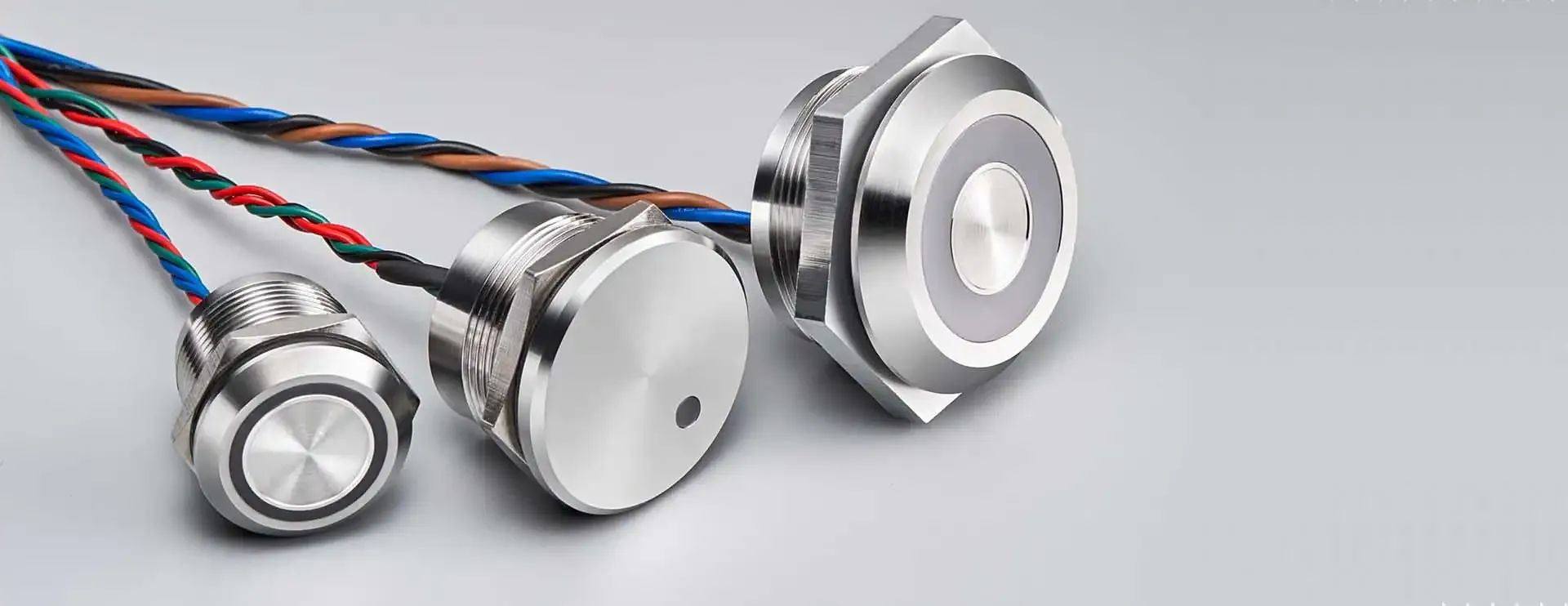

Langir’s Capacitive Switches: Meeting Industrial Durability and Reliability Standards

Langir’s switches are engineered with corrosion-resistant stainless steel bezels, boast IP65–IP69K ratings, and feature reinforced PCBs, ensuring dependable operation under repeated wash-downs, extreme temperatures, and significant mechanical stress. This robust combination supports demanding industrial lifecycles with unparalleled resilience.

Real-World Case Studies: Acrylic Integration in Industrial Control Panels

In a recent food-processing line retrofit, Langir’s capacitive switches, protected by 4 mm acrylic panels, successfully withstood daily high-pressure cleaning cycles for over two years without any loss of sensitivity. Similarly, an outdoor access control kiosk equipped with 5 mm acrylic lenses remained fully operational through humidity swings ranging from 10% to 95%, demonstrating exceptional resilience.

Troubleshooting Common Issues with Capacitive Switches and Acrylic Integration

Sealing switches behind acrylic can introduce sensitivity shifts, false activations, or missed actuations if not properly addressed with expert solutions.

Preventing False Triggers Through Acrylic: Causes and Solutions

False triggers often originate from moisture condensation on the panel surface or proximity to grounded metal. Implementing driven shields around the electrode and applying advanced firmware filters effectively reduces noise coupling and prevents spurious activations, ensuring reliable operation.

Calibrating Sensitivity for Varying Acrylic Thicknesses

Most advanced sensor modules feature adjustable gain or multi-level sensitivity profiles. Calibrating through built-in menus or via I²C commands ensures that thick panels register reliably while thin panels avoid accidental activation, optimizing performance across diverse applications.

Best Practices for Noise Reduction and Environmental Interference Mitigation

- Utilize grounded metal backplates to stabilize the reference field and enhance signal integrity.

- Employ shielded cables and adhere to proper PCB grounding techniques to minimize electrical interference.

- Activate oversampling and debounce filters within the sensor firmware to improve signal stability.

These measures collectively mitigate EMI, static discharge, and capacitive crosstalk, ensuring robust performance in challenging industrial settings.

Langir’s Customization Services for Acrylic Panel Integrated Capacitive Switches

Langir offers comprehensive, end-to-end customization—precisely tailoring electrode patterns, panel thickness compatibility, and bulk manufacturing to your exact specifications.

Get a quote for custom capacitive switches from Langir

Custom Design Options for Acrylic-Compatible Capacitive Switches

Our design options include bespoke electrode geometries, precision acrylic lens cutouts, custom illumination colors, and specific IP ratings. Our expert engineers can meticulously adjust hardware and firmware parameters to perfectly match any acrylic overlay thickness and shape, ensuring optimal performance.

Langir’s Approach to Bulk Orders and Supply Chain Management for Industrial Clients

With ISO-certified processes, Langir efficiently scales high-volume production while ensuring consistent part-to-part performance and unwavering quality. Our dedicated supply-chain teams expertly manage lead times, component sourcing, and logistics for seamless, on-time delivery to industrial clients worldwide.

Requesting Custom Capacitive Switch Solutions: Our Streamlined Process

To discuss bulk capacitive switches precisely tailored to your acrylic panels or to explore design prototypes, please visit our Contact Us page and complete the inquiry form. Our dedicated team will promptly collaborate with you on technical drawings, prototypes, and production schedules to bring your vision to life.

Capacitive Switches and Acrylic Compatibility | FAQs

These insights address common inquiries, reinforcing key design considerations for optimal performance.

Can Capacitive Touch Operate Through Thick Acrylic Panels?

Capacitive touch can indeed operate effectively through acrylic up to 8–10 mm thick when paired with high-sensitivity sensor modules and optimized electrode layouts, ensuring reliable activation without false triggers.

What Materials Are Compatible with Capacitive Switch Technology?

Various non-conductive overlays such as acrylic, polycarbonate, glass, and ceramic all robustly support capacitive sensing, provided their dielectric constants and thicknesses fall within the switch’s design tolerances for optimal performance.

How Do Environmental Conditions Affect Capacitive Switch Performance Through Acrylic?

Humidity, temperature, and moisture can subtly shift the dielectric constant and thickness of acrylic. Therefore, sensors equipped with auto-tuning, robust shielding, and advanced firmware filtering are essential to maintain consistent performance in diverse environmental conditions.

Choosing Between Capacitive and Mechanical Switches for Acrylic Interfaces

Capacitive switches offer sealed, wear-free operation, tailored illumination, and superior hygiene advantages, while mechanical switches provide tactile feedback and simpler electronics. For sealed, high-cycle, or wash-down environments, capacitive designs integrated behind acrylic are often the preferred, more durable solution.

Seamless acrylic integration transforms user interfaces with reliable, sealed capacitive switching that endures the most demanding industrial conditions. By selecting the right panel thickness, material grade, and electrode design—and leveraging Langir’s custom engineering and bulk-order capabilities—you will achieve durable, high-performance touch solutions. Explore your project’s unique needs and request tailored prototypes today.

EN

EN