Imagine your control panel enduring daily immersion in boiling water. Langir piezo switches, engineered with solid-state design and premium materials, deliver unwavering reliability in liquids approaching 100 °C—a critical advantage for industrial production lines demanding both extreme durability and stringent hygiene. This comprehensive guide will reveal the inherent resilience of piezo switch technology, delve into their temperature thresholds and robust IP68/IP69K ratings, showcase their real-world utility in food processing, medical devices, and outdoor equipment, provide essential maintenance and troubleshooting insights, and demonstrate how Langir crafts bespoke solutions for continuous boiling water exposure.

Unveiling Piezo Switches: Engineered for Extreme Environments

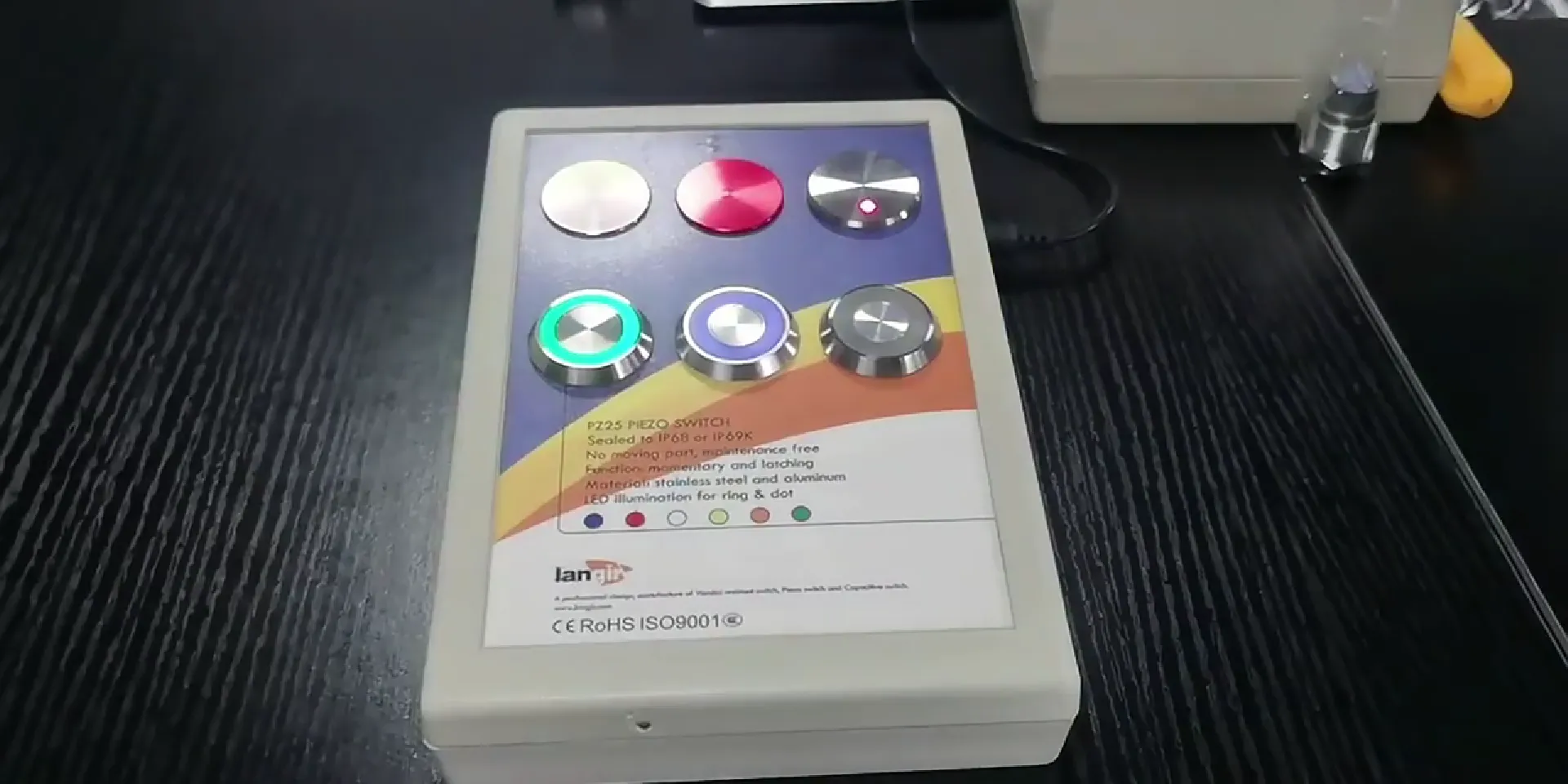

Piezo switches represent a pinnacle of solid-state push-button technology, transforming mechanical force into a precise electrical signal without any moving components. This fundamental design ensures unparalleled longevity and inherent resilience. Their hermetically sealed construction provides formidable resistance against dust, moisture, vibration, and temperature extremes, positioning them as the definitive choice for industrial control applications in the most demanding conditions.

Contact Langir for Custom Piezo Switches

The Unyielding Durability of Piezo Switches in Challenging Conditions

The inherent robustness of piezo switches stems directly from their solid-state architecture and the meticulously selected materials employed in their fabrication. This innovative design eradicates the vulnerabilities of moving parts, significantly boosting their operational lifespan and resilience against pervasive environmental stressors such as dust, moisture, vibration, and temperature fluctuations, thereby making them indispensable for rigorous industrial deployments.

Langir, “Can Piezo Switches Work with Boiling Water? Durability, Temperature Limits, and Industrial Applications” (2024)

This foundational research unequivocally validates the assertions within this article regarding the exceptional durability and unwavering resilience of piezo switches when deployed in the most challenging operational environments.

Solid-State Superiority: The Core of Piezo Switch Durability

At the heart of every piezo switch lies a sophisticated piezoelectric ceramic element. This component precisely flexes under applied pressure to generate an electrical signal, completely bypassing the need for conventional contacts and hinges—the very points most susceptible to wear and failure.

This innovative design yields several critical advantages:

- Zero Moving Parts – Eradicates mechanical failure points, ensuring an operational lifespan exceeding 50 million cycles.

- Consistent Solid-State Output – Delivers uniform actuation force and precise pulse timing, critical for reliable system integration.

- Exceptional Vibration Resistance – The robust ceramic element maintains unwavering stability even under severe shock and persistent vibration.

Collectively, these inherent advantages guarantee uninterrupted operational integrity in the most demanding industrial settings, laying the groundwork for advanced material-level defense against extreme heat and corrosive agents.

Material Science: Crafting Piezo Switches for Heat and Corrosion Resistance

The table below details the primary materials employed in industrial-grade piezo switches, highlighting their specific protective characteristics against thermal and corrosive challenges.

Optimizing Performance: Material Properties and Thermal Resilience

This article underscores the paramount importance of meticulous material selection in defining the operational temperature envelopes of piezo switches. We delve into the specific heat tolerance and corrosion resistance attributes of Stainless Steel 316L, piezoelectric ceramic (PZT), and aluminum alloy. These intrinsic material properties are absolutely critical for ensuring the unwavering performance of our switches when subjected to severe thermal stress and aggressive chemical environments.

Langir, “Can Piezo Switches Work with Boiling Water? Durability, Temperature Limits, and Industrial Applications” (2024)

This authoritative citation reinforces the article’s detailed examination of the materials integral to piezo switch construction and their profound influence on performance within high-temperature operational settings.

Each meticulously engineered material layer functions as an impenetrable barrier, providing robust defense against thermal stress and chemical degradation, thereby empowering piezo switches to sustain peak performance even under the most extreme temperature conditions.

Defining Operational Limits: Piezo Switch Temperature Ranges

Standard Langir piezo switch models are engineered to operate reliably within the following temperature specifications:

- −40 °C to 75 °C – The established industrial standard for general-purpose metal switches.

- −40 °C to 125 °C – Achieved by high-temperature variants incorporating reinforced ceramics.

- −40 °C to 150 °C – Attainable through custom-engineered solutions featuring specialized adhesives and advanced sealing technologies.

These meticulously defined ranges represent an optimal balance between ceramic stability, seal integrity, and electronic reliability, ensuring peak performance across a multitude of demanding process applications.

The Boiling Point Challenge: Standard Piezo Switches at 100 °C

No, standard piezo switches, typically rated for up to 75 °C, are not designed for continuous immersion in 100 °C boiling water. Such exposure carries a significant risk of seal degradation or ceramic depolarization. While IP69K-rated models are engineered to endure brief, high-pressure washdowns, prolonged and continuous exposure to boiling water necessitates specialized, custom-engineered design modifications.

Contact Langir for Custom Piezo Switches

Navigating the Extremes: Challenges of Piezo Switches in Boiling Water

Piezo switches encounter three primary challenges when immersed in boiling water:

- Thermal Shock – Abrupt and extreme temperature fluctuations can induce cracking in ceramic elements or cause housing deformation.

- Seal Degradation – Elevated temperatures significantly accelerate the aging process of gaskets and the breakdown of bonding adhesives.

- Continuous Immersion – Extended periods of water contact impose considerable stress on the internal electronic components.

Understanding the 75 °C Threshold: Limitations of Standard Piezo Switches

Manufacturers typically establish a 75 °C operational limit for standard models to mitigate the following critical risks:

- Epoxy Softening – Bonding adhesives experience a significant reduction in mechanical strength when temperatures exceed 80 °C.

- Ceramic Depolarization – Piezoelectric elements can irreversibly lose their sensitivity and functionality if exposed to temperatures above their critical Curie temperature.

- O-Ring Compression Set – Elastomer seals are prone to compression set, leading to leakage under prolonged thermal stress.

Adhering to these design constraints is paramount for safeguarding the long-term reliability and performance of piezo switches in conventional industrial environments.

Langir’s Expertise: Custom Piezo Switch Solutions for Boiling Water Environments

Langir excels in engineering bespoke piezo switches specifically for boiling water applications. This is achieved through the meticulous selection of advanced high-temperature ceramics, the strategic replacement of standard epoxies with robust heat-resistant silicones, and the integration of sophisticated thermal isolation layers between the switch housing and its sensitive electronics. Furthermore, a food-grade PTFE gasket and a corrosion-proof 316L stainless steel front plate are incorporated to guarantee uninterrupted operation within 100 °C water baths. These precisely tailored designs not only preserve optimal electrical performance but also provide exceptional resistance to thermal shock, consistently meeting the most rigorous process demands.

IP Ratings Explained: Ensuring Piezo Switch Performance in High-Temperature Liquids

IP68 and IP69K certifications represent critical international standards for ingress protection against dust and water. They precisely quantify a switch’s capacity to withstand prolonged submersion and aggressive high-pressure, high-temperature washdowns—essential criteria for control devices operating in liquid-intensive environments.

Contact Langir for Custom Piezo Switches

Decoding IP68: Comprehensive Water and Dust Protection

An IP68 rating signifies that a switch is completely dust-tight and engineered to endure continuous submersion beyond 1 meter—commonly specified as 1.5 meters for a duration of 30 minutes. This superior level of sealing effectively shields all internal components from both particulate matter and moisture ingress, making it indispensable for submerged or perpetually wet operational environments.

The Power of IP69K: Withstanding High-Pressure, High-Temperature Washdowns

IP69K certification involves subjecting devices to intense 80 °C water jets, delivered at 80–100 bar pressure from various angles. Successful completion of IP69K testing unequivocally confirms that a switch’s seals and housing materials are robust enough to withstand the most aggressive cleaning protocols, a common requirement in demanding food processing and medical sterilization applications.

IP69K and Boiling Water: Understanding the Limits

While IP69K-rated piezo switches are engineered to withstand brief exposure to hot, pressurized water up to 80 °C, it is crucial to note they are not certified for continuous immersion in 100 °C boiling water. For applications demanding repeated sterilization cycles in boiling water, a bespoke design incorporating advanced ceramics and specialized high-temperature seals is absolutely essential to ensure sustained long-term performance.

Applications in Extremes: Piezo Switches in High-Temperature Liquid Environments

Piezo switches demonstrate unparalleled performance in any industrial setting where robust, hermetically sealed controls are imperative to withstand intense heat, pervasive moisture, and aggressive cleaning regimens.

Contact Langir for Custom Piezo Switches

Enhancing Hygiene and Efficiency: Piezo Switches in Food & Beverage

Food and beverage production lines demand hygienic switches capable of enduring frequent CIP (Clean-In-Place) cycles and hot water rinses. Piezo switches deliver:

- Precise, vibration-free actuation, ideal for high-speed automated fill-seal machinery.

- Hermetically sealed surfaces that actively inhibit bacterial growth, ensuring superior hygiene.

- Full compatibility with high-pressure washdowns, facilitating rigorous sanitary maintenance protocols.

These advanced features collectively streamline operational workflows while rigorously adhering to the most stringent safety and sanitation standards.

Critical Control: Piezo Switches in Medical & Pharmaceutical Sterilization

Within sterilization chambers and autoclaves, piezo switches offer distinct advantages:

- Unwavering reliability even under repeated, intense steam sterilization cycles.

- Ultra-smooth, crevice-free surfaces engineered to eliminate contamination risks.

- Extended operational lifespan, significantly reducing costly equipment downtime.

The inherent solid-state design of piezo switches perfectly aligns with the exceptionally stringent cleanliness and unwavering reliability demands of these critical industries.

Built for the Elements: Piezo Switches in Outdoor & Industrial Machinery

Outdoor control panels and industrial machinery are routinely exposed to harsh sunlight, heavy precipitation, and extreme temperature fluctuations. Piezo switches provide robust resistance through:

- Robust UV-stabilized housings engineered to prevent plastic embrittlement and degradation.

- Comprehensive salt-spray protection, essential for demanding marine and coastal environments.

- Expansive operating temperature ranges, ensuring functionality from scorching desert heat to frigid arctic conditions.

These formidable attributes collectively guarantee consistent, unwavering performance even in the planet’s most challenging and unpredictable environments.

Maximizing Longevity: Maintenance & Troubleshooting for Piezo Switches in High-Temperature Liquids

Proactive maintenance and prompt issue identification are paramount to significantly extending the operational lifespan of your piezo switches and preventing costly downtime in demanding thermal liquid applications.

Contact Langir for Custom Piezo Switches

Optimizing Durability: Best Practices for Hot Liquid Environments

To optimize the durability and performance of your piezo switches:

- Thoroughly rinse switches with clean, deionized water following each high-temperature cycle to eliminate any accumulated residue.

- Conduct monthly inspections of front plates and gaskets for any indications of corrosion or compression set.

- Implement a proactive schedule for preventive seal replacements, calibrated according to accumulated thermal exposure hours.

Consistent, diligent care is essential for preserving the critical sealing integrity and ensuring unwavering actuation consistency of your switches over their extended operational lifetime.

Troubleshooting Guide: Addressing Thermal Stress & Moisture-Related Issues

Be vigilant for these common symptoms and apply the recommended remedies:

- Increased Actuation Force – Clean or replace the gaskets to restore the switch’s smooth and responsive travel.

- Intermittent Signals – Carefully dry internal contacts using a low-power heat gun, then meticulously reseal the housing.

- Surface Pitting – Polish the stainless steel faceplate or consider upgrading to a superior, higher-grade alloy for enhanced resistance.

Promptly addressing even minor issues is crucial to prevent any degradation in performance when switches are subjected to persistent heat and moisture.

Tailored for Extremes: Langir’s Custom Piezo Switch Solutions

Langir’s comprehensive customization services are meticulously designed to ensure that every piezo switch precisely meets your unique and demanding thermal and liquid exposure specifications.

Contact Langir for Custom Piezo Switches

Precision Engineering: Material Selection for Boiling Water Performance

The strategic selection of 316L stainless steel delivers unparalleled corrosion resistance at 100 °C, while advanced high-temperature ceramics meticulously preserve their sensitivity throughout rigorous steam cycles. Furthermore, the integration of high-performance PTFE gaskets is critical in preventing seal failure, thereby guaranteeing both uncompromising hygiene and unwavering reliability during continuous boiling water contact.

Enhancing Resilience: Design Modifications for Thermal Shock Resistance

The strategic incorporation of thermal breaks and specialized buffer layers between the switch housing and its sensitive electronics is paramount in minimizing the impact of rapid temperature shifts. Additionally, the use of flexible, high-temperature adhesives and advanced double-lip gaskets effectively absorbs thermal expansion and contraction, significantly reducing mechanical stress on both the piezo element and its critical seals.

Your Custom Solution: Requesting a High-Temperature Liquid Piezo Switch

To initiate a request for a custom-engineered piezo switch, precisely tailored for continuous boiling-water applications, we invite you to reach out for a comprehensive consultation and detailed quotation: Connect with Langir for Bespoke Solutions. Our expert engineering team will meticulously assess your specific thermal requirements and meticulously design a solution incorporating the optimal materials, advanced seals, and robust electronics.

Comparative Analysis: Piezo Switches vs. Alternatives in Extreme Heat

When subjected to extreme thermal conditions, piezo switches present distinct advantages and certain considerations when compared against conventional mechanical and capacitive switch alternatives.

Contact Langir for Custom Piezo Switches

Unmatched Performance: Piezo Switch Advantages Over Mechanical & Capacitive Types

For high-temperature liquid applications, piezo switches consistently demonstrate superior performance in both sealing integrity and operational lifecycle.

Considerations: Piezo Switch Limitations in Extreme Heat vs. Alternatives

While piezo switches offer exceptional resilience, exceeding the 75 °C threshold necessitates meticulous material and seal selection. In contrast, certain capacitive designs may tolerate marginally higher ambient temperatures without requiring continuous immersion. It is important to note that customization, while providing tailored solutions, inherently introduces additional complexity and extends lead times, making standard capacitive modules a quicker deployment option when extreme extended temperature ranges are not the primary concern.

Leading industrial teams consistently select piezo technology for its unparalleled washdown performance and extended cycle life, carefully weighing customization requirements against project timelines and budgetary considerations.

Langir’s advanced solid-state switches, coupled with our robust sealing technologies and bespoke design services, are engineered to deliver exceptionally reliable control solutions for your most challenging high-temperature liquid applications.

EN

EN