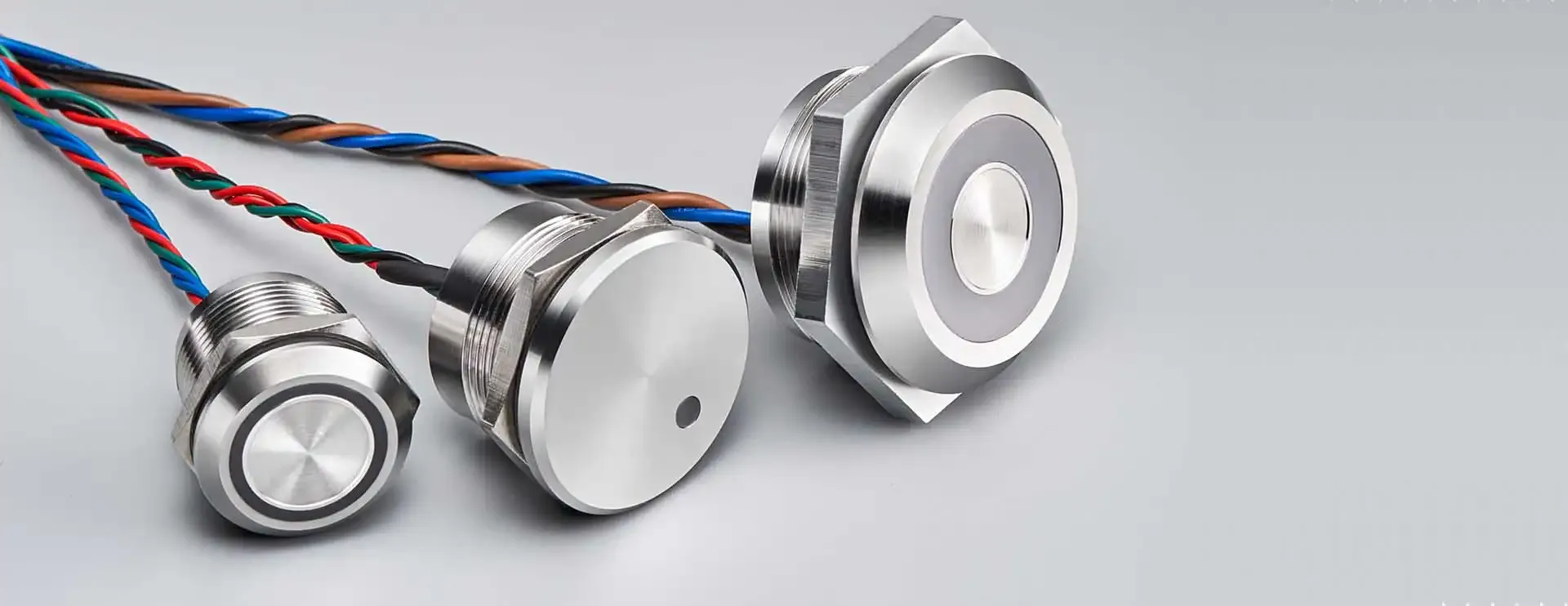

Capacitive switch technology fundamentally redefines industrial durability, eliminating the wear-prone moving parts inherent in mechanical switches. This comprehensive guide explores how superior cycle ratings, robust failure resistance, unparalleled environmental resilience, strategic cost advantages, and tailored customization options position Langir’s capacitive push button switches as the definitive choice for demanding industrial manufacturing. We’ll delve into lifespan metrics, common mechanical vulnerabilities, the exceptional performance of sealed capacitive designs in challenging conditions (dust, moisture, vibration), and how Langir’s standard and bespoke solutions deliver enduring value. Join us as we outline critical durability factors, performance enhancements, maintenance efficiencies, and core technical principles to empower your selection of the optimal switch for your control panels and automation systems.

Capacitive vs. Mechanical Switches: Unmatched Lifespan for Industrial Operations

Capacitive switches consistently surpass mechanical counterparts by tens of millions of actuations, a direct result of their static electrode design that eliminates friction points and contact bounce. While a typical mechanical push button delivers 1–5 million cycles, a capacitive touch switch routinely achieves over 50 million cycles in industrial applications, ensuring years of uninterrupted service. This significant lifespan advantage directly translates to reduced downtime and substantial cost savings in mission-critical industrial settings.

Get a quote for custom capacitive switches from Langir

Switch Lifespan: A Direct Durability Comparison

Capacitive switches consistently deliver a significantly extended operational lifespan compared to mechanical switches, frequently surpassing 50 million cycles in demanding industrial environments. This superior durability directly translates into minimized downtime and substantial reductions in replacement costs for critical applications.

Langir, Do Capacitive Switches Last Longer Than Mechanical Switches? Ultimate Durability Guide for Industrial Applications (2024)

This citation directly supports the core premise of this guide, offering a clear comparison of the superior cycle ratings and lifespan advantages inherent to capacitive switch technology over traditional mechanical designs.

No Moving Parts: The Core of Extended Capacitive Switch Lifespan

A capacitive switch detects touch through an electrostatic field, entirely bypassing the need for mechanical springs and physical contacts. This innovative design eliminates sliding contacts, pivot joints, and the associated physical abrasion, metal fatigue, or spring deformation. This inherently static construction prevents common failure modes like electrical arcing and corrosion, which severely curtail mechanical switch longevity, thereby ensuring consistent, reliable actuation performance across tens of millions of operations.

Defining Durability: Typical Cycle Ratings for Capacitive vs. Mechanical Switches

The following durability comparison clearly illustrates the average industrial cycle ratings and their corresponding performance thresholds for various switch types.

Capacitive sensors consistently deliver 10–20 times more operational cycles than even the most robust hardened mechanical designs, firmly establishing them as the premier choice for high-duty industrial applications.

Optimizing Longevity: Factors Affecting Capacitive Switch Service Life in Industrial Use

Several operational and environmental factors determine a capacitive switch’s effective service life:

- Extreme temperatures exceeding specified operational limits can accelerate electronic drift.

- Sustained high humidity or condensation may gradually alter dielectric layers.

- Persistent vibration, if mounting hardware is not adequately secured, can lead to loosening.

- Direct chemical exposure (e.g., acids, solvents) has the potential to degrade protective coatings.

Precise specification of operational temperature ranges, appropriate IP ratings, and robust enclosure materials is crucial to ensure capacitive switches maintain peak durability and performance even under the most challenging industrial conditions.

Maintenance Impact: Maximizing Lifespan for Capacitive and Mechanical Switches

While routine inspection and cleaning can extend mechanical switch life by mitigating debris and corrosion, these activities inherently necessitate periodic downtime. In stark contrast, capacitive switches require minimal maintenance—typically limited to occasional surface wipe-downs and, rarely, firmware recalibration—thereby virtually eliminating service interruptions. Proactive, scheduled checks for enclosure seal integrity and connector stability are generally sufficient to ensure consistent capacitive performance over extended operational periods.

Common Failure Modes: Mechanical Switches in Industrial Environments

Mechanical push button switches are inherently susceptible to failure primarily due to wear, contact degradation, spring fatigue, and electrical arcing—all exacerbated by repeated operational cycles and challenging industrial environments.

Get a quote for custom capacitive switches from Langir

Mechanical Switch Performance: The Impact of Wear and Tear

Wear manifests as increased actuation force, diminished tactile feedback, and problematic contact bounce. The metal-to-metal interfaces within mechanical switches inevitably develop pitting and surface roughness, leading to intermittent conductivity or complete operational failure. As wear progresses, switch actuation becomes increasingly unreliable, potentially triggering false starts or unregistered presses, thereby severely undermining critical process control.

Corrosion and Contact Degradation: A Major Factor in Mechanical Switch Failure

The ingress of moisture, dust, and aggressive chemicals initiates detrimental electrochemical reactions on mechanical contact surfaces. Resulting corrosion films significantly increase contact resistance, leading to undesirable voltage drops and erratic switching behavior. Degraded contacts can unpredictably stick closed or open, causing unplanned equipment shutdowns and introducing significant safety hazards.

Spring Fatigue and Arcing: Key Contributors to Mechanical Switch Failure

Repeated compression cycles inevitably weaken spring steel, diminishing return force and resulting in ‘sticky’ or sluggish actuation. Concurrently, electrical arcing that occurs each time contacts separate erodes contact plating, significantly accelerating wear. Over prolonged use, the combined effect of weakened springs and eroded contacts renders the mechanical switch inoperable.

Operational Consequences: The Impact of Mechanical Switch Failures

Industrial lines experience:

- Unplanned Downtime – Unexpected switch failures directly halt production.

- Increased Maintenance Burden – Reactive repairs divert critical resources.

- Compromised Quality – Missed or duplicated commands degrade product consistency.

Mitigating these detrimental outcomes necessitates either frequent, costly switch replacements or a strategic transition to inherently longer-lasting, more reliable alternatives.

Capacitive Switches: Engineered for Durability in Harsh Industrial Environments

Capacitive technology demonstrates exceptional performance in outdoor and wash-down environments, primarily due to its combination of robust sealed enclosures and inert sensing layers that inherently resist contamination and mechanical shock.

Get a quote for custom capacitive switches from Langir

Sealed Designs: Protecting Capacitive Switches from Dust, Moisture, and Chemicals

Capacitive push buttons frequently carry IP67 or IP69K ratings, signifying that their touch surface and housing effectively prevent the ingress of particulates and high-pressure water jet spray. Fully potted electronics and precisely gasketed front panels create an impenetrable barrier against corrosive agents, ensuring reliable and consistent operation in demanding applications such as food processing, chemical plants, and outdoor installations.

Environmental Resilience: The Capacitive Switch Advantage

Capacitive switches, by virtue of their sealed designs and the complete absence of moving parts, demonstrate superior resistance to the most challenging industrial environments. They are frequently rated IP67 or IP69K, providing robust protection against dust, moisture, and chemical exposure, making them ideally suited for the most demanding applications.

Langir, Do Capacitive Switches Last Longer Than Mechanical Switches? Ultimate Durability Guide for Industrial Applications (2024)

This citation reinforces the article’s assertions regarding the significant environmental advantages of capacitive switches, particularly their proven ability to withstand the challenging conditions prevalent in sectors such as food processing and chemical manufacturing.

What Materials Enhance Capacitive Switch Durability?

The strategic utilization of premium alloys and advanced ceramics ensures Langir’s capacitive switches maintain unparalleled structural and electrical integrity even under prolonged and intense operational stress.

Capacitive Technology: Resisting Vibration and Temperature Extremes

The inherent absence of moving components allows capacitive switches to flawlessly tolerate high-frequency vibration and rapid temperature fluctuations without succumbing to mechanical loosening or metal fatigue. Advanced electronic calibration algorithms actively compensate for temperature-induced capacitance drift, ensuring consistently reliable touch detection across an expansive range from –40 °C to +85 °C.

Key Industrial Applications Benefiting from Capacitive Switch Durability

Industries that demand sealed, maintenance-free interfaces include:

- Food and beverage processing

- Pharmaceutical manufacturing

- Outdoor signage and kiosks

- Heavy machinery controls

- Cleanroom operations

Across these diverse sectors, capacitive switches consistently deliver reduced downtime, simplified sanitation protocols, and robust resistance to rigorous chemical wash-downs.

Capacitive Switches: Advantages Beyond Exceptional Longevity

Capacitive switches offer a comprehensive suite of performance and ergonomic benefits that extend far beyond mere cycle life metrics, enhancing overall operational efficiency.

Get a quote for custom capacitive switches from Langir

High Sensitivity: Improving User Experience and Reducing Operator Fatigue

The inherently low actuation force and complete absence of a tactile click significantly reduce finger strain during repetitive operations. Consistent, precise touch thresholds minimize user error, leading to faster operator response times and substantially less fatigue in high-volume control panel environments.

The Importance of Sleek, Flat Design for Industrial Control Panels

Modern industrial control panels increasingly prioritize optimal hygiene and simplified cleaning procedures.

- Flat, seamless surfaces eliminate crevices that can trap contaminants.

- Uniform front panels significantly streamline and simplify wipe-down procedures.

- Integrated backlit capacitive faces enhance visibility and usability in low-light environments.

This combination of aesthetic appeal and functional simplicity directly accelerates maintenance workflows and improves operational efficiency.

Capacitive Switches: Driving Down Downtime and Maintenance Costs

Sealed capacitive units eliminate the need for frequent mechanical switch replacements and the associated lubrication requirements. This reduction in service calls and optimized parts inventory directly translates to a significantly lower total cost of ownership, faster line changeovers, and fewer disruptive production interruptions.

Cost Considerations for Bulk Industrial Capacitive Switch Purchases

When procuring capacitive switches in volume, consider the following strategic cost implications:

Higher order volumes unlock significant price breaks that compound with the inherent reduction in operational expenses, delivering substantial long-term value over the entire equipment lifespan.

Langir Customization: Tailoring Capacitive Push Button Switches for Industrial Needs

Langir seamlessly integrates our renowned standard durability with extensive tailored options, precisely meeting unique automation specifications and ensuring flawless integration with optimal performance.

Get a quote for custom capacitive switches from Langir

Customization Options: Size, Material, and Backlighting for Langir Capacitive Switches

Langir’s capacitive switches can be specified with:

- Diameter ranges from 16 mm to 30 mm for precise panel fit-out.

- Front-plate materials available in robust stainless steel, durable glass, or inert ceramic.

- Customizable backlighting colors and intensities, compatible with 24V, 12V, or 5V systems.

These extensive options ensure optimal touch performance perfectly aligns with both aesthetic preferences and stringent environmental requirements.

Langir Integration: Seamlessly Incorporating Capacitive Switches into Existing Industrial Systems

Our expert engineering team provides comprehensive PCB footprints, detailed wiring diagrams, and optimized firmware profiles, ensuring seamless compatibility with common PLCs, HMIs, and custom controllers. Pre-configured ESD protection and advanced signal conditioning modules further simplify field installation and significantly reduce commissioning time.

Industrial Sectors Benefiting from Langir’s Customized Switches

Clients in these verticals leverage our solutions:

- Automotive assembly lines, for robust, glove-friendly cabin controls.

- Food processing plants, requiring CIP-rated wash-down stations.

- Medical device manufacturers, for sterile, sealed operator panels.

- Outdoor vending and kiosk operators, demanding weatherproof and vandal-resistant interfaces.

Across each of these critical sectors, clients consistently experience enhanced uptime and assured compliance with rigorous industry standards.

How to Request Quotes or Custom Solutions from Langir

To explore competitive bulk pricing or discuss bespoke switch designs tailored to your precise requirements, please request a quote for bulk capacitive switches. Our dedicated team will expertly guide you through detailed specifications, lead times, and sample evaluations.

The Science Behind Capacitive Touch Technology and Its Durability Impact

Capacitive sensing fundamentally leverages minute changes in an electrostatic field to detect touch, thereby entirely eliminating mechanical wear and inherently maximizing service life.

Get a quote for custom capacitive switches from Langir

Capacitance Change Detection: How Capacitive Switches Operate

A capacitive sensing element precisely registers a change in its electrical field when a finger or conductive object approaches, subtly altering the measured capacitance. The integrated onboard controller then accurately translates this minute shift into a distinct actuation event, requiring absolutely no physical movement.

Anatomy of Durability: Key Components of a Capacitive Switch

Key parts include:

This meticulously engineered assembly consistently delivers unparalleled reliable operation, particularly in challenging environments where traditional mechanical components are prone to failure.

Capacitive Sensing: The Mechanism for Eliminating Mechanical Wear

By fundamentally replacing wear-prone springs and contacts with advanced solid-state detection, capacitive switches entirely circumvent friction, metal fatigue, and arcing erosion. This inherent absence of moving parts guarantees consistent, reliable performance across hundreds of millions of actuations.

Recent Advances: Elevating Capacitive Switch Performance

Modern enhancements include:

- Active Drift Compensation – Dynamically maintains sensitivity across wide temperature swings (e.g., ±40 °C).

- Multi-Touch Detection – Accurately distinguishes simultaneous touches, enabling advanced interface capabilities.

- Integrated Self-Test Routines – Continuously monitors electrode health and provides proactive alerts on potential degradation.

FAQs: Capacitive vs. Mechanical Switch Durability

Engineers and plant managers frequently seek concise, authoritative answers regarding core durability concerns. Below, we address the most common queries directly and without unnecessary jargon, empowering you to make informed decisions.

Are Capacitive Switches More Durable Than Mechanical Switches?

Unequivocally, yes. Capacitive switches significantly outlast mechanical switches due to their fundamental operation without moving contacts, thereby eliminating the friction, spring fatigue, and electrical arcing that inherently limit mechanical lifespans.

Do Capacitive Sensors Experience Wear Over Time?

Capacitive sensors themselves do not experience mechanical wear. However, their external protective coatings and sealing gaskets may require periodic inspection after prolonged exposure to harsh chemicals or intense UV radiation to ensure the continued integrity of their IP ratings.

What Are the Primary Disadvantages of Capacitive Switches Compared to Mechanical?

Common trade-offs include:

- Higher initial unit cost.

- Potential sensitivity to extreme EMI/RFI without adequate shielding.

- Typically fingertip-only actuation, which may require specialized tuning for gloved operators.

Crucially, these factors can be effectively mitigated through strategic design choices and precise calibration.

How Long Do Mechanical Switches Typically Last in Industrial Use?

Standard industrial mechanical switches typically endure between 1 and 5 million cycles, with their lifespan heavily dependent on environmental severity and contact materials. This often necessitates replacement every 6–24 months in demanding, heavy-use applications.

Can Capacitive Switches Endure Extreme Industrial Conditions?

Properly specified and IP-rated capacitive switches are engineered to thrive in dusty, wet, high-vibration, and chemical-exposed industrial settings, consistently maintaining reliable actuation even where conventional mechanical devices inevitably fail.

Capacitive technology unequivocally establishes a new benchmark in operational life and environmental resistance, fundamentally redefining durability for the most demanding industrial applications. Carefully consider your specific use case, maintenance protocols, and total cost of ownership to select the optimal solution that maximizes both uptime and return on investment. Ready to elevate your control panels with Langir’s industry-leading capacitive push button switches? Contact us today to discuss your precise requirements and secure a durable, high-performance interface engineered for your production environment.

EN

EN