Capacitive switches seldom need lubrication. They are solid‑state sensors that detect changes in capacitance instead of relying on mechanical contacts, so oils and greases add no operational benefit and can even harm performance. This guide explains how capacitive sensing works, why lubrication is unnecessary (and sometimes detrimental), and how maintenance for industrial installations focuses on sealing, cleaning, and calibration rather than mechanical servicing. You’ll find a clear comparison with mechanical switches, practical cleaning and inspection recommendations, and notes on customization and bulk procurement to help engineers and maintenance managers specify or replace capacitive switch technology with confidence. Throughout, we emphasize durability, IP ratings, cleaning protocols, and supplier capabilities relevant to large or custom orders.

How Do Capacitive Switches Work Without Moving Parts?

Capacitive switches register touch or proximity by measuring tiny changes in capacitance at a sensor electrode when a conductive object—like a finger—disturbs the local electric field. The controller keeps a baseline reading and interprets significant deviations as an actuation, producing a digital signal for the host system without any mechanical movement. Because there are no springs, stems, or metal-to-metal contacts, there’s no friction or wear to manage, which improves reliability and reduces maintenance. Capacitive sensing also works through thin non‑metallic surfaces and can be fully sealed, making it ideal for industrial and hygienic environments where ingress protection is essential.

Get a quote for custom capacitive switches from Langir

What Is the Capacitive Switch Technology Behind Touch Sensing?

A typical capacitive switch uses a sensor electrode, a dielectric surface, and a controller that detects minute capacitance shifts and filters electrical noise. The electrode acts as one plate of a virtual capacitor; when a finger or conductive tool approaches, the effective capacitance rises and the controller’s ADC or dedicated sensing ASIC registers the change. Onboard signal processing separates deliberate touches from background variation, delivering stable performance even in electrically noisy industrial settings. Common use cases include sealed control-panel buttons behind glass or plastic, where the switch provides a reliable, protected operator interface.

How Does Non-Mechanical Design Eliminate the Need for Lubrication?

Lubricants address friction and wear between moving parts—an issue capacitive switches don’t have because they lack mechanical actuation. With no sliding stems, springs, or exposed contacts, there are no surfaces that benefit from oil or grease. Applying lubricants to a capacitive surface can reduce sensitivity, contaminate seals, and attract debris, which undermines long‑term reliability. Maintenance therefore shifts from greasing and mechanical adjustment to straightforward cleaning, gasket inspection, and occasional firmware or threshold tuning to keep sensing consistent.

Why Is Lubrication Unnecessary for Industrial Capacitive Switches?

No—capacitive switches do not require lubrication. Their sensing relies on electric fields rather than moving parts, and industrial units are built with solid‑state sensors and rugged housings that remove classic mechanical maintenance needs. Introducing lubricants risks changing the dielectric properties of the sensing surface, degrading sensitivity, and compromising seals. Maintenance teams should replace routine lubrication tasks with targeted inspection and cleaning that preserve both performance and hygienic standards.

Get a quote for custom capacitive switches from Langir

How Do Capacitive Switches Differ from Mechanical Switches Regarding Maintenance?

Mechanical switches depend on physical contacts and moving elements that wear, so they need lubrication, contact replacement, and frequent adjustments. Capacitive switches have no sliding mechanisms or exposed contacts; their primary failure modes involve electronic component stress, surface contamination, or seal failure rather than mechanical wear. For procurement and uptime planning, this means more predictable lifecycles, fewer field interventions, and reduced mean time to repair for operator interfaces. Buyers should prioritize sealed housings and robust controllers to mitigate environmental risks instead of budgeting for lubrication-related upkeep.

What Are the Common Misconceptions About Lubing Capacitive Switches?

Many habits formed around mechanical switches carry over incorrectly to capacitive designs—like assuming every button needs lubrication to “feel” smooth or last longer. Capacitive switches don’t rely on friction for feel; any tactile feedback is typically provided by haptics. Another misconception is that lubricants protect against corrosion: while oils can help metal parts, they offer no benefit for sealed, non‑mechanical sensors and often attract contaminants. In practice, proper sealing, cleaning routines, and controller calibration are the maintenance priorities—not lubricant application.

What Are the Advantages of Maintenance-Free Capacitive Switches?

Maintenance‑free capacitive switches deliver clear operational advantages in industrial settings: longer service life because there are no moving parts to wear, better hygiene from sealed surfaces that tolerate cleaning, and less unplanned downtime thanks to fewer maintenance tasks. These benefits lower total cost of ownership and make production schedules more predictable—especially where frequent cleaning or harsh environments would shorten the life of mechanical interfaces. Capacitive switches also integrate smoothly with modern HMIs, allowing touch-through glass or plastic bezels and minimizing ingress points for liquids and particulates. The result is a reliable operator interface that aligns with automation and hygienic design needs.

This comparison section highlights procurement considerations engineers should weigh when choosing between capacitive and mechanical switch approaches.

This side‑by‑side illustrates why capacitive switches typically deliver lower long‑term maintenance costs and improved suitability for harsh or sanitary environments compared with mechanical alternatives.

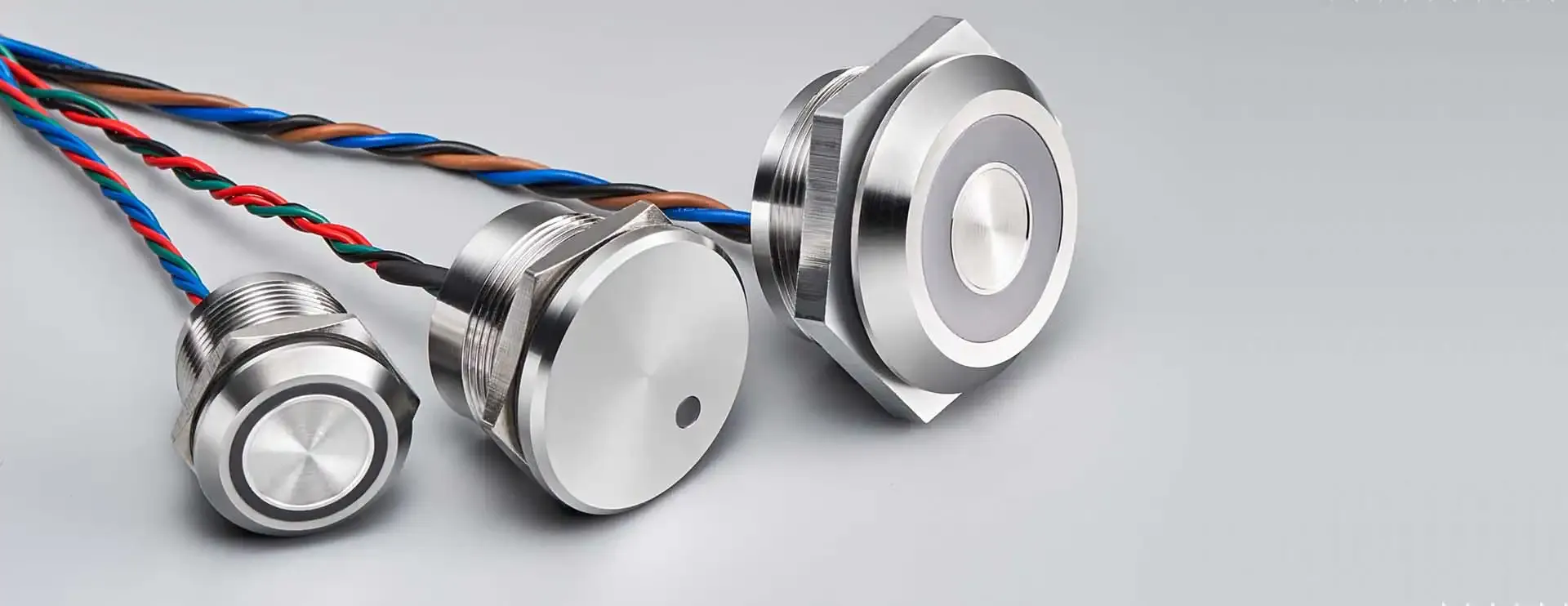

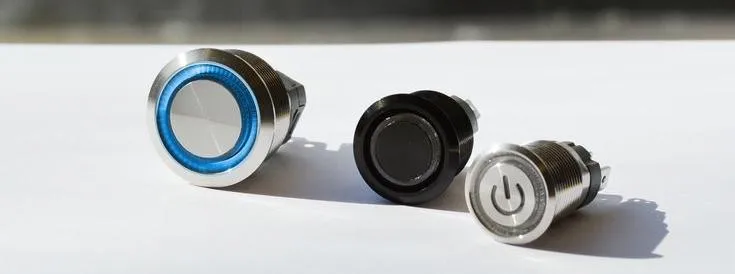

Langir positions its capacitive switches as rugged, low‑maintenance options for harsh and hygienic applications. Our sealed panel switch designs support these operational benefits, and we can handle bulk orders and customization to meet industrial deployment requirements. This supplier note points buyers toward where to source production‑ready capacitive switches.

How Does Durability and Longevity Benefit Industrial Applications?

Durable capacitive switches translate into higher uptime and lower service costs because control panels stay reliable over long production runs without routine mechanical servicing. Longer lifespans simplify spare‑part planning and reduce replacement cycles compared with mechanical buttons that need contact or spring changes. For procurement teams, specifying capacitive switches reduces planned maintenance windows and makes mean time between failures easier to predict—driven mainly by electronics and environmental exposure. In practice, this yields less downtime and a clearer replacement schedule for continuous manufacturing and processing operations.

Why Are Capacitive Switches Ideal for Harsh and Hygienic Environments?

Sealed capacitive switch assemblies can achieve IP ratings that protect against dust and water ingress, making them well suited to food processing, medical devices, and outdoor kiosks where cleaning and exposure are routine. Because capacitive sensing works through non‑metallic materials such as glass or plastic, the user surface can remain fully sealed while still detecting touch reliably. That combination supports aggressive cleaning regimens without exposing electronics to contaminants. Industries that require frequent sanitization or operate in corrosive atmospheres benefit from the reduced ingress risk and simpler cleaning procedures offered by capacitive designs.

How Can Custom Capacitive Switch Solutions Enhance Industrial Performance?

Custom capacitive switch solutions let you adapt bezel size, sealing, labeling, and electrical interfaces to fit specific application constraints—improving integration, ergonomics, and reliability. Choosing the right actuation area, IP rating, and interface protocol helps designers match switches to control‑panel layouts and environmental demands. Customization reduces retrofit complexity, ensures consistent behavior across production units, and supports volume deployments with repeatable specs. We also support bulk supply of push‑button switches and tailored services to meet customer needs.

Before the customization options table, consider how product features translate into operational benefits for industrial users and procurement teams evaluating bulk or tailored supplies.

This mapping helps buyers link technical choices to operational advantages, enabling clearer specifications for custom orders and consistent field performance.

What Customization Options Does Langir Offer for Capacitive Switches?

Langir provides customization for our standard capacitive switch range, including adjustments to form factor, sealing, and labeling to meet customer specifications. We supply push‑button switches in bulk and offer customization services such as modified bezel shapes, enhanced IP ratings for wet environments, custom legends or colors for operator guidance, and tailored electrical interfaces for specific control systems. Specifying these options during quotes helps align samples, lead times, and production schedules.

Outlining these common choices clarifies how specification decisions affect installation and maintenance. For volume purchases, defining attributes up front speeds sample approval and production.

How Do Bulk Capacitive Switch Orders Support Industrial Needs?

Bulk orders deliver cost savings, parts consistency, and simplified logistics for manufacturers deploying many operator interfaces across machines or sites. Volume purchasing lowers unit cost, ensures identical specifications across batches, and lets suppliers manage lead times to match production. Quality controls—sample runs, incoming inspection, and agreed test plans—keep assemblies consistent. For OEMs, request datasheets, sample approvals, and documented MOQ and lead‑time commitments early when planning to scale with capacitive switch suppliers.

- Bulk procurement offers predictable unit pricing and simplified inventory management.

- Volume orders enforce consistent part specifications and reduce variation across production units.

- Early agreement on samples, testing, and lead times avoids delays during ramp-up.

These advantages make bulk purchasing an efficient path for companies standardizing on capacitive technology across product lines or facilities.

What Are the Best Practices for Maintaining Capacitive Switches Without Lubrication?

Maintenance for capacitive switches centers on cleaning, seal inspection, firmware/calibration checks, and environmental monitoring—rather than lubrication or mechanical servicing. A routine checklist preserves sensitivity and service life: use approved cleaners, inspect gaskets and bezel seals, verify controller firmware and thresholds, and check the sensor surface for damage. Regular cleaning and inspections maintain hygiene and prevent contaminants from altering dielectric properties. Integrating these steps into existing maintenance schedules reduces unexpected failures and keeps operator interfaces reliable in demanding industrial contexts.

Get a quote for custom capacitive switches from Langir

Before the cleaning checklist below: use approved methods to protect sensor coatings and seals—avoid solvents and abrasives that can cause damage.

- Clean with mild, non-abrasive detergents: Use neutral pH cleaners and soft cloths to remove residue without damaging surfaces.

- Inspect seals and gaskets regularly: Check for compression set, cracks, or displacement that could allow ingress.

- Verify controller calibration: Run calibration routines after cleaning or environmental changes to ensure consistent sensitivity.

- Avoid oils, solvents, and abrasive pads: These substances can alter dielectric properties and attract contaminants.

Following this checklist keeps capacitive interfaces hygienic and reliable while avoiding actions that would degrade sensing performance or compromise seals. The next step is matching waterproof and seal ratings to real‑world cleaning and exposure conditions.

How Should You Clean and Care for Capacitive Touch Switches?

Clean capacitive touch switches with mild, non‑abrasive detergents and soft microfiber cloths. Avoid solvents, oils, and abrasive pads that can damage coatings or change the sensor’s dielectric behavior. Cleaning frequency depends on the environment: high‑hygiene areas such as food or medical facilities may need daily cleaning, while industrial control rooms may follow weekly or monthly cycles. After cleaning, inspect bezels and gaskets visually and test actuation to confirm sensitivity remains correct. Use manufacturer‑recommended cleaners where available and log cleaning cycles to correlate maintenance with long‑term performance.

Are Capacitive Switches Waterproof and Sealed for Industrial Use?

Yes—capacitive switches can be designed to meet IP65, IP67, or IP69 through gasketed housings and sealed interfaces, providing protection against dust and varying levels of water ingress. IP65 resists water jets and dust; IP67 tolerates temporary immersion; IP69 withstands high‑pressure, high‑temperature washdowns. Choose the rating that matches your cleaning procedures and exposure. Higher IP ratings reduce ingress‑related inspections but require correct gasket selection and precise panel cutouts during installation. Match environmental exposure and cleaning practices to the appropriate IP level for reliable, long‑term operation.

Do Capacitive Switches Need Lubrication | FAQs

What are the key benefits of using capacitive switches in industrial applications?

Capacitive switches deliver longer service life because they have no moving parts, which reduces mechanical wear. Their sealed designs improve hygiene and allow thorough cleaning without exposing internal components. They also cut downtime by lowering maintenance needs and enable flexible design because they can sense through glass or plastic surfaces—useful where cleanliness and durability are priorities.

How do environmental factors affect the performance of capacitive switches?

Temperature, humidity, and contaminants can affect capacitive switch performance. High humidity may change the dielectric properties of the sensing surface and affect sensitivity, while dust and debris can disturb the electric field and cause false activations or reduced responsiveness. Selecting the right IP rating and keeping a consistent cleaning and inspection routine are key to reliable operation in challenging environments.

Can capacitive switches be used in outdoor applications?

Yes. When specified with appropriate sealing and IP ratings, capacitive switches work well outdoors. Ratings such as IP65, IP67, or IP69 protect against dust and water ingress, making these switches suitable for kiosks, outdoor control panels, and equipment exposed to the elements. Always match the switch’s sealing level to the actual environmental stresses it will face.

What maintenance practices should be followed for capacitive switches?

Focus on regular cleaning, seal inspections, and firmware or calibration checks rather than lubrication. Use mild, non‑abrasive cleaners, inspect seals for wear, and verify controller calibration periodically. A routine maintenance schedule helps prevent contamination and keeps switches operating reliably over time.

How do capacitive switches compare to mechanical switches in terms of cost-effectiveness?

Capacitive switches often provide better long‑term cost-effectiveness because they require less maintenance and last longer. Although their initial price can be higher, the lack of mechanical wear points reduces replacement and servicing costs, lowering total cost of ownership—especially where downtime and maintenance are expensive.

What customization options are available for capacitive switches?

Capacitive switches can be customized in form factor, sealing level, labeling, and electrical interface. Typical options include different bezel sizes, higher IP ratings for wet environments, custom legends or backlighting, and specific output protocols to simplify PLC integration. These choices improve fit and usability for the intended application.

Are there any specific industries that benefit most from capacitive switch technology?

Yes—industries that demand hygiene and durability benefit most, including food processing, pharmaceuticals, medical devices, and outdoor equipment. Capacitive switches’ sealed designs and touch‑through capabilities help maintain cleanliness and resist contaminants, supporting strict hygiene and safety standards.

Do Capacitive Switches Require Any Lubrication at All?

No—capacitive switches do not require lubrication. They rely on electric‑field sensing, not moving contacts that create friction; lubricants won’t improve operation and can interfere with sensor performance. Instead, use approved cleaning agents and inspect seals periodically to maintain reliable actuation. For procurement, specify sealed, maintenance‑free designs to avoid lubrication‑based maintenance cycles and to support hygienic cleaning procedures.

How Long Is the Lifespan of a Capacitive Switch Compared to Mechanical Switches?

Capacitive switches typically offer longer service life for user interfaces because they remove mechanical wear points; electronics and the environment become the main life drivers instead. Lifespan depends on exposure to contaminants, sealing effectiveness, and electrical stress rather than actuation cycles. Buyers should request lifecycle or MTBF data from suppliers and run representative sample tests to validate expected service life and replacement timing.

We supply push‑button switches in bulk and provide customization services to help teams transition from mechanical to capacitive solutions. This supplier‑focused approach aligns procurement with production schedules, reduces field maintenance burdens, and ensures tailored specifications meet operational needs. If you need scalable, sealed capacitive panel switches for industrial deployment, consider discussing bulk and customization options with manufacturers experienced in panel switch production and supply.

Conclusion

Capacitive switches offer meaningful advantages in industrial settings: extended service life, improved hygiene, and reduced maintenance. Recognizing their maintenance‑free nature lets engineers and procurement teams make informed choices that boost operational efficiency. By prioritizing sealed designs, appropriate IP ratings, and correct cleaning protocols, organizations can ensure reliable performance in demanding environments. For tailored solutions and volume supply, contact experienced manufacturers to align specifications, samples, and lead times with your production needs.

EN

EN