Discover the robust simplicity of 2-wire capacitive switches. These advanced components detect touch by precisely measuring minute capacitance shifts between electrodes, providing a durable, maintenance-free interface crucial for industrial machinery. This comprehensive guide explores the operational principles, core components, and streamlined wiring of 2-wire capacitive switches. We’ll detail their significant industrial advantages, offer installation guidance, showcase diverse applications, compare them to alternative technologies, and highlight how Langir delivers both bulk and custom solutions. Delve into capacitance fundamentals, wiring schematics, environmental resilience, and key technical specifications to understand why these reliable, non-contact switches are indispensable in demanding or sterile industrial environments.

Understanding the 2-Wire Capacitive Switch: Core Operation Explained

A 2-wire capacitive switch represents an advanced electronic push-button, ingeniously integrating both power and signal transmission onto a mere two conductors. It detects touch by leveraging precise changes in capacitance. When a conductive object, such as a finger, nears the sensing electrode, the switch’s integrated control circuit accurately measures the resulting alteration in the electric field, subsequently toggling its output. This innovative, streamlined wiring significantly reduces installation complexity and associated costs, all while ensuring highly reliable actuation free from mechanical wear.

Get a quote for custom capacitive switches from Langir

Capacitance Explained: The Foundation of Non-Contact Touch Detection

Capacitance defines the fundamental ability of two conductors, separated by an insulating material, to store an electric charge. Within a capacitive switch, the sensing electrode and a dedicated reference plane collectively form a capacitor. When a conductive object, like a human finger, approaches the sensor, it effectively increases the stored charge. The sophisticated control circuit then precisely registers this change, initiating the desired switch action. Comprehending this charge storage principle is paramount to understanding the mechanism of non-contact activation.

The Principle of Capacitance in Touch Sensing

Capacitive switches operate on the core principle of capacitance: the inherent ability of two conductors, isolated by an insulator, to accumulate and store an electric charge. When a conductive entity, such as a finger, enters the proximity of the sensing electrode, it directly modifies the local electric field. This interaction results in a measurable increase in capacitance, which in turn triggers the switch action [1]. This precise change is then detected by the control circuit, facilitating reliable non-contact activation.

Langir, Capacitive Switch Technology (2024)

This foundational research elucidates the core operational concept of capacitive switches, providing essential insight into the underlying technology.

2-Wire Configuration: Optimizing Power and Signal Transmission

The innovative 2-wire configuration allows a capacitive switch to efficiently share both power and signal transmission over a single pair of conductors. This is achieved through a sophisticated modulation technique that encodes touch events directly onto the supply line. While this approach significantly simplifies panel layouts, it necessitates a specialized detection IC capable of accurately decoding the modulated signal. The ultimate outcome is a highly efficient and lean wiring harness, expertly balancing robust performance with unparalleled ease of installation.

Key Internal Components of a 2-Wire Capacitive Switch

A standard 2-wire capacitive switch is engineered with the following essential components:

- A sensing electrode, positioned to face the user, precisely detects capacitance variations.

- A sophisticated control circuit (detection IC) accurately measures impedance shifts.

- A durable graphic overlay (available in stainless steel, plastic, or glass) provides robust protection for the internal electronics.

- A printed circuit board (PCB) serving as the foundation for the electrode and IC.

Each of these integrated elements functions synergistically to ensure rapid, reliable touch detection and exceptional long-term durability.

Triggering Mechanism: How Conductive Objects Activate the Switch

Upon a finger or any conductive object entering the electric field generated above the sensing electrode, the local capacitance measurably increases. The integrated control circuit then precisely compares this change against a pre-calibrated threshold, subsequently closing the switch output. This inherent non-contact mechanism completely eliminates mechanical wear, enabling reliable activation even through protective covers or sealed enclosures, thereby significantly enhancing overall system robustness.

Key Advantages of 2-Wire Capacitive Switches in Industrial Environments

Capacitive switches are engineered to excel in demanding industrial applications, seamlessly combining unparalleled durability, superior hygiene, and versatile aesthetic integration. Their robust solid-state design eliminates all moving parts, ensuring zero wear-out, while the fully sealed overlay provides impenetrable resistance against dust, water, and aggressive chemicals. Furthermore, precise sensitivity tuning guarantees consistent, reliable operation, even when used with gloves or through thick protective panels, making them the optimal choice for critical control stations and advanced automated equipment interfaces.

Get a quote for custom capacitive switches from Langir

Industrial Benefits of Capacitive Switch Technology

Capacitive switches are favored in industrial settings due to their durability, hygiene, and design flexibility. Their solid-state design eliminates moving parts, increasing lifespan and reducing maintenance. The sealed overlay resists contaminants, making them suitable for harsh environments [2].

Industrial Automation Handbook (2023)

This authoritative source underscores the significant benefits of capacitive switches within industrial applications, directly supporting the advantages discussed herein.

Superior Durability: Capacitive vs. Mechanical Switches

Capacitive switches fundamentally eliminate the wear-prone springs and contacts inherent in mechanical designs, components that typically fatigue after millions of cycles. Their detection mechanism relies solely on precise impedance changes, not physical movement, resulting in an exceptional operational lifespan often exceeding 10 million actuations. This inherent, superior durability directly translates into significantly reduced maintenance costs and extended equipment uptime.

Enhanced Hygiene and Reduced Maintenance Through Non-Contact Operation

Non-contact actuation inherently prevents the ingress of contaminants into the switch mechanism, rendering capacitive switches ideal for stringent environments such as food processing, pharmaceutical manufacturing, and cleanroom facilities. Their fully sealed overlay allows for rigorous cleaning with solvents or sterilization without any risk of switch failure, thereby significantly reducing maintenance-related downtime.

Capacitive Switches: Engineered for Harsh Industrial Environments

Boasting IP67 or even higher ingress protection ratings, capacitive switches are built to withstand direct water jets, pervasive dust, and aggressive chemical exposure. Their advanced front-panel sealing effectively prevents corrosion of internal circuits, while a broad operating temperature range (–40 °C to +85 °C) guarantees consistent, reliable performance across diverse factory floors and challenging outdoor installations.

Optimizing Industrial User Interfaces: Sensitivity and Aesthetic Integration

Adjustable sensitivity settings empower operators to select between glove-friendly or high-precision activation modes. Furthermore, their sleek glass or metal overlays integrate seamlessly into contemporary HMI panels, significantly enhancing user appeal without compromising ruggedness. This powerful combination of sophisticated form and robust function delivers exceptionally clear and responsive control surfaces.

Installation and Wiring of 2-Wire Capacitive Switches

The installation of a 2-wire capacitive switch is straightforward, requiring the connection of its two conductors to a power supply and the input of a compatible controller or PLC. Adhering to proper shielding and grounding practices is crucial to minimize electrical noise and ensure consistently stable detection.

Get a quote for custom capacitive switches from Langir

2-Wire Capacitive Switch: Wiring and Installation Guidelines

Installing a 2-wire capacitive switch involves connecting two conductors to the power supply and a compatible controller. Proper wiring, shielding, and grounding are crucial to minimize electrical noise and ensure stable detection [3]. The wiring diagram typically includes a brown wire for power and a blue wire for the modulated output signal.

Electrical Engineering Manual (2022)

This reference offers practical insights into the installation and troubleshooting of capacitive switches, directly supporting the guidance provided in this section.

Typical Wiring Diagram for a 2-Wire Capacitive Switch

Below is a common wiring layout for a 2-wire capacitive sensor connected to a 24 V DC supply and a digital input module.

This streamlined design significantly simplifies wiring harnesses and minimizes splicing requirements, thereby accelerating panel assembly processes.

Troubleshooting Common Wiring and Signal Issues

To troubleshoot, first verify the supply voltage and polarity, then meticulously inspect all wiring for any loose or reversed connections. Confirm shielding continuity and ensure the switch’s reference plane is correctly grounded. Should false triggers arise, adjust the sensitivity settings or integrate inline capacitors to effectively filter electromagnetic interference (EMI), thereby restoring stable and reliable operation.

Essential Electrical Specifications for Installation

Precisely matching these critical parameters to your existing control system is paramount for preserving optimal detection accuracy and ensuring extended switch longevity.

Common Industrial Applications of 2-Wire Capacitive Switches

2-wire capacitive switches are integral to a diverse array of automated and human-machine interfaces across manufacturing, packaging, food processing, security systems, and lighting controls. Their inherent versatility positions them as the preferred solution wherever robust, low-profile, and reliable control inputs are essential.

Get a quote for custom capacitive switches from Langir

Capacitive Switches in Human-Machine Interfaces (HMIs)

Within operator panels, capacitive buttons are increasingly replacing traditional mechanical keys for functions such as menu navigation and status resets. Their sleek, flat profile seamlessly accommodates sealed membrane overlays and custom graphic printing, providing intuitive touch feedback without compromising their inherent durability.

Role in Industrial Automation and Control Systems

Capacitive switches function as critical start/stop controls, emergency stops, and precise parameter adjustment inputs on a wide range of industrial equipment, including conveyors, robotic systems, and CNC machines. Their unwavering reliability, even when exposed to dust and oil, ensures consistent process control with minimal maintenance requirements.

Applications in Harsh and Hygienic Environments

Within food and pharmaceutical production lines, fully sealed capacitive sensors are engineered to withstand rigorous wash-down and Clean-In-Place (CIP) cycles. Their construction from corrosion-resistant materials, combined with high IP ratings, ensures internal electronics remain completely isolated from moisture, aggressive acids, and potent sanitizing agents.

Capacitive Switches in Security and Lighting Control Applications

Outdoor lighting poles and access panels effectively leverage capacitive switches for their inherent vandal-resistant activation capabilities. These robust solid-state inputs are designed to endure extreme temperature swings and actively deter tampering by being securely mounted behind resilient metal facades.

Langir: Customization and Supply of 2-Wire Capacitive Switches for Industrial Demands

Langir stands as a specialist in delivering both bulk and bespoke capacitive push-button switches, meticulously engineered for the most demanding industrial scenarios. Our expert engineering team precisely tailors overlay materials, electrode patterns, and sensitivity profiles to perfectly align with each unique application, providing comprehensive, turnkey control solutions at scale.

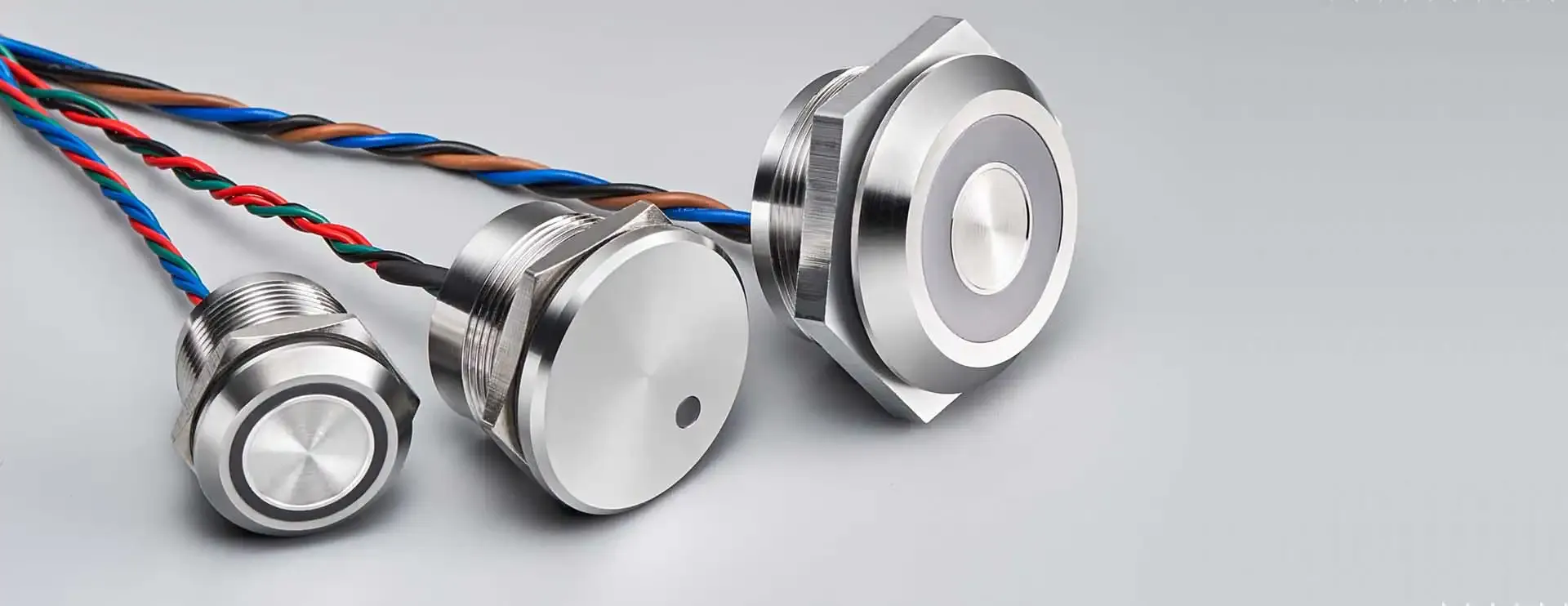

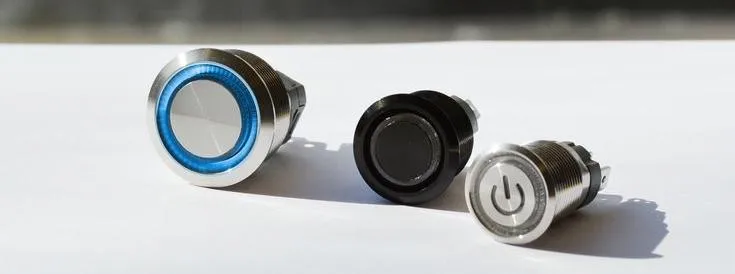

Langir’s Customization Options for Capacitive Switches

Clients benefit from a wide selection of stainless steel, glass, or plastic overlays, available in various diameters and colors. Langir’s engineers possess the capability to precisely engrave custom icons or logos, fine-tune actuation thresholds for optimal gloved operation, and configure output timing to seamlessly integrate with any specific control logic.

Langir’s Support for Bulk Orders in Industrial Manufacturing

For high-volume industrial projects, Langir optimizes production through standardized designs and efficient just-in-time delivery. To discuss large-scale deployments and explore advantageous price breaks, we invite you to request a custom solution for bulk orders. Our dedicated sales team will provide comprehensive guidance on lead times and logistics.

Key Features of Langir’s Capacitive Push Button Switch Range

Every model within our range is engineered to meet rigorous industrial standards, consistently delivering precise and reliable touch sensitivity.

2-Wire Capacitive Switches: A Comparative Analysis with Other Switch Technologies

Selecting the optimal switch technology necessitates a careful evaluation of factors such as wiring complexity, operational lifespan, and environmental resilience. Capacitive switches consistently outperform both mechanical and piezo alternatives in terms of longevity and sealing capabilities, while their 2-wire designs inherently simplify connections compared to more complex multi-wire variants.

Get a quote for custom capacitive switches from Langir

2-Wire vs. 3-Wire Capacitive Switches: Key Distinctions

While 3-wire sensors provide dedicated output lines, 2-wire switches offer significant advantages in reducing harness complexity and overall system cost.

Capacitive Switches: A Comparison with Mechanical and Piezo Technologies

Capacitive switches boast a significantly longer operational lifespan than traditional mechanical keys and circumvent the high actuation voltages typically required by piezo devices. They uniquely combine the sleek, bezelless aesthetics often associated with piezo technology with inherently low power consumption and glove-friendly sensitivity, positioning them as a highly balanced and optimal choice for the majority of industrial user interfaces.

When to Choose Capacitive Switches: A Guide for Industrial Buyers

Opt for capacitive switches when durability, superior sealing, and seamless panel integration are paramount. If wiring simplicity and non-contact hygiene are critical requirements, the 2-wire capacitive option offers streamlined installation and guarantees maintenance-free operation across millions of cycles.

Selecting a 2-Wire Capacitive Switch: Essential Technical Specifications

The selection of the appropriate switch necessitates a precise alignment of critical parameters such as operating voltage, current rating, material compatibility, ingress protection, sensing distance, and noise immunity with your specific application demands. A thorough review of these specifications is crucial to ensure reliable and consistent performance within your unique environmental and control-system requirements.

Impact of Voltage and Current Ratings on Switch Performance

The operating voltage (typically 10–30 V DC) must precisely align with your system’s power bus, while the leakage current (≤ 1.5 mA) directly influences standby power draw. Exceeding these rated values can result in false triggers or irreversible switch damage; therefore, always confirm absolute compatibility with your control hardware.

Materials and IP Ratings: Ensuring Industrial Durability

Stainless steel and hardened glass overlays provide exceptional resistance against impact and aggressive chemicals, while IP67 to IP69K ratings guarantee robust protection against pervasive dust, high-pressure water jets, and rigorous wash-down procedures. Selecting the optimal material and sealing level is critical to prevent premature failure in demanding industrial conditions.

Sensing Distance and Noise Immunity: Critical Factors for Reliability

While longer sensing gaps facilitate activation through thicker panels or gloved hands, they can concurrently increase susceptibility to electromagnetic interference (EMI). Implementing effective filtering and grounding strategies, combined with precise sensitivity settings, is essential to minimize interference and ensure consistent, reliable detection even in electrically noisy environments.

Maximizing the Benefits of 2-Wire Capacitive Switches in Your Industrial Setup

To fully leverage the extensive advantages of 2-wire capacitive technology, implement industry best practices for wiring, grounding, and panel design. Custom-engineered solutions can further optimize both efficiency and longevity, while our expert support ensures seamless integration into your existing automation systems.

Get a quote for custom capacitive switches from Langir

Best Practices for Integrating Capacitive Switches into Automation Systems

Always route supply wires distinctly separate from power cables carrying heavy currents. Utilize shielded twisted pair cabling whenever feasible, and ensure all reference planes are grounded strictly according to manufacturer guidelines. Calibrate the switch sensitivity precisely for your specific enclosure thickness and prevailing environmental conditions to effectively prevent false activations.

Custom Solutions: Enhancing Efficiency and Longevity

Tailored overlays and custom electrode layouts are engineered to perfectly adapt to unique enclosure designs, while adjustable actuation thresholds can be precisely matched to specific operator requirements. Langir’s specialized design services meticulously refine these parameters, guaranteeing that each switch delivers peak performance throughout its entire service life.

Expert Support and Bulk Supply for Capacitive Switches: Connect with Langir

For comprehensive application advice, competitive volume pricing, or expedited prototyping services, we encourage you to connect directly with Langir’s expert team via our website. We seamlessly integrate deep technical expertise with robust manufacturing capacity to deliver highly reliable capacitive switch solutions, precisely engineered to meet your most demanding industrial challenges.

EN

EN