Ever wondered what goes on when you press your car horn? This post explains how a car horn switch works in simple, clear terms. It breaks down the basic circuit, explores the button mechanism, and follows the electrical journey during activation. Readers will learn key wiring steps and how to diagnose horn issues. This guide aims to help you troubleshoot or upgrade your automotive horn switch quickly and effectively.

The Basic Circuit of a Car Horn System

This section breaks down a car horn circuit. It shows how the battery acts as the power supply, the relay handles heavy current loads like an airbag switch in a steering column, and the horn switch completes the circuit. Plus, a fuse and electrical tape keep things safe. Each part works in sync for a reliable signal.

Contact Langir for Custom Car Horn Switches

The Role of the Battery as the Power Source

The battery stands as the heartbeat of the horn circuit, quietly powering up what gets everyone’s attention when pressed. It’s like using a trusty screwdriver to tighten up loose ends, ensuring the horn sends a clear signal without fuss—just like a reliable golf cart cruising in compressed air mode, backed by a warranty that keeps consumers confident about how does a car horn work.

How the Horn Relay Manages High Current

The horn relay acts as the muscle for a motor vehicle’s horn system by handling heavy current like a seasoned pro, pushing through high loads so the horn can work flawlessly—think of it as a trusty component in a jeep that keeps transport secure even when a stubborn stripper component might otherwise falter:

Completing the Circuit Through the Horn Switch

The horn switch completes the circuit by connecting the battery to the engine of the horn system, triggering the fuel of electrical energy to sound the signal. It uses a quick solder connection that echoes the precision of a tire’s balance and the responsiveness of a diaphragm, ensuring every push delivers a clear honk:

- Battery powers the circuit

- Solder secures the connection

- Horn switch routes the current

- Diaphragm creates the sound

- Engine-like reliability drives performance

This setup gives industrial clients a simple, robust solution that speaks to efficiency and safety.

The Function of the Fuse in Protecting the Horn Circuit

The fuse acts like a guardian in this setup, snapping into action to protect the circuit when things heat up unexpectedly. It ensures that custom car horn switches keep working, even when the stainless steel components of the horn system experience bursts of onomatopoeia-like signals, prompting engineers to explore safer, more reliable designs.

Inside the Car Horn Button Switch Mechanism

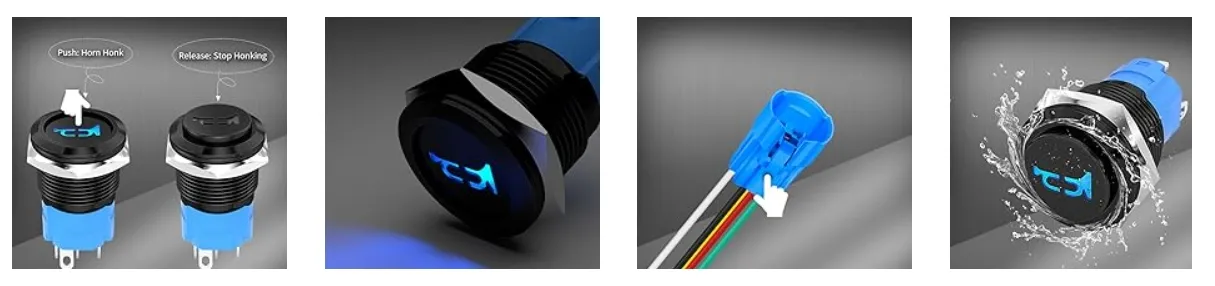

Inside this section, engineers pinpoint the horn switch assembly within the network of components. Pressing the button closes electrical contacts built from durable metal, while a spring mechanism quickly resets the switch. The setup uses quality materials like a precise solenoid and reliable compressor-grade voltage control to ensure every press counts.

Contact Langir for Custom Car Horn Switches

Locating the Horn Switch Assembly

The assembly sits in a tight spot that even a seasoned auto mechanic finds interesting—almost like a well-used wire stripper in a toolbox. Every electron flows in sync, almost like a wave hitting a shore, to trigger the train horn with precision. Locating the horn switch assembly tells the story of careful design and efficient power management, ensuring that each press is perfectly aligned for performance.

How Pressing the Button Closes Electrical Contacts

When the button is pressed, it forces two metal connectors together, closing the electrical circuit and powering the horn, much like a remote control sending a clear signal to grab attention. With every press, precise wires align and shift the pitch of the sound, ensuring it works as reliably as a spare tire in a pinch.

Materials Used for Switch Contacts

The switch contacts use tough metals that act like a screw tightening up the safety and performance of the switch mechanism, ensuring every press works reliably on the road. The materials are chosen to work smoothly with the integrated valve system and support the electromagnet’s power as it drives each signal safely and consistently:

Spring Mechanism for Button Return

The spring mechanism in the car horn switch offers a quick, efficient return for the button after it’s pressed, ensuring that signals from the horn are crisp and clear. This clever design works like a brake system to stop over-extension, much like a boat correcting its course against the current, and keeps the panel’s operation smooth and reliable for every honk.

The Electrical Journey When Activating the Horn

The journey starts when the car horn button on the steering wheel sends a clear signal. This kicks off the horn relay coil, boosting the electric current that sends power to the horn unit. Next, a solid grounding path completes the flow of electricity. This process works smoothly, whether you’re in green South Africa or anywhere else.

Contact Langir for Custom Car Horn Switches

Initial Signal From the Car Horn Button Switch

The first signal from the car horn button switch sends a clear command through the vehicle’s wiring, letting the system know to drill into action and continue powering the horn. The process, initiated right from the dashboard, shows expertise in every circuit and makes troubleshooting a breeze even on the busiest workday.

Activating the Horn Relay Coil

The horn relay coil fires up when the ignition system cranks the volt, sending a surge through the coil. It handles tiny vibrations like a tonneau rolling over a bump, while a sturdy plastic casing keeps everything secure and focused on triggering the horn’s signal with precision.

Relay Switching Power to the Horn Unit

The relay switches power to the horn unit with the efficiency of a well-oiled gear, smoothly channeling energy like a pump following a clear wiring diagram for a headlamp upgrade. This switch action clears the way for consistent honk performance that meets practical needs without any extra fuss.

Grounding Path Completion for Horn Operation

The grounding path completes the horn operation by connecting the circuit with precision, ensuring that every crimp, frequency check, and steering input aligns for a sharp sound effect when activated. This secure setup, verified by expert tool usage and careful installation, keeps the system reliable and responsive:

Common Types of Automotive Horn Switches

Steering wheel horn buttons, clock spring connections, aftermarket push button installs, and stalk-mounted switches each play a key role in noise control and communication. This diagram-like overview offers practical insights into how lighting cues and bell-like signals operate, setting the stage for a closer look at each unique design and its function.

Contact Langir for Custom Car Horn Switches

Steering Wheel Mounted Horn Buttons

Steering wheel mounted horn buttons offer a neat design that keeps control close at hand, and they’re built around a solid factory-grade understanding of automotive systems, similar to setting up a cart with smooth wheels. These components are designed to handle precise amounts of ampere, ensuring that the signal works like a lightweight javascript function running error-free. They also consider the impact of automotive lighting and other systems to deliver reliable performance on every press.

Clock Spring Connection for Steering Wheel Switches

The clock spring connection keeps the horn switch moving smoothly on the steering wheel by letting the wire run through tight threads without breaking contact Langir, ensuring every thread of electricity flows correctly; this design lets manufacturers share robust performance across models and maintain a solid thread of connectivity during every press:

- Wire management for consistency

- Smooth rotation with durable threads

- Reliable contact Langir performance

- Effective sharing of power flow

Aftermarket Push Button Horn Installations

Aftermarket push button horn installations offer a straightforward solution for upgrading a vehicle horn. The design follows a clear schematic, making wiring as simple as aligning a wheel, while steel components provide the durability needed for long-term reliability. This system, trusted by experts, ensures that each press triggers a precise train of electrical signals for a crisp, dependable honk.

Stalk-Mounted Horn Activation Switches

Stalk-mounted horn activation switches offer a direct way to operate the horn—keeping the signal immediate and reliable, much like a musical instrument that perfectly emulates the sound of a trumpet; this mount is often found in trucks where quick, efficient response is key. When the switch is pressed, a clear signal moves through the circuit, triggering the horn with precision and power:

- Streamlined design for ease of use

- Robust performance under heavy-duty conditions

- Quick activation to match fast-paced driving

Steps for Wiring a Car Horn to a Switch

Engineers set up a car horn switch by choosing a solid push button horn switch for that air horn power feel, pinpointing power and ground points like a motorcycle account on decibel levels, and slotting a horn relay into the mix for reliable performance. They connect the switch to the relay control circuit and route wires safely, as seen on the internet.

Contact Langir for Custom Car Horn Switches

Selecting an Appropriate Push Button Horn Switch

Engineers choose the right push button horn switch by checking the transfer case connection and ensuring firm terminal attachments to avoid issues during troubleshooting while achieving an ideal sound; they inspect each component carefully for a reliable installation:

- Evaluate the transfer case connection

- Check terminal integrity

- Conduct troubleshooting tests

- Verify sound quality

Identifying Power Source and Ground Points

Engineers pinpoint the battery as the heart of the circuit while tracking down a solid ground connection to complete the horn setup. They quickly locate these points to ensure a seamless and reliable wiring job that makes every honk count.

Integrating a Horn Relay Into the Wiring

Engineers integrate a horn relay into the wiring to ensure the horn receives the right current without risking overheating. They methodically connect the relay with secure solder joints so each signal translates into a clear, audible honk—a setup that works reliably even in tough industrial applications. This precise approach gives users reassurance that every press of the horn button kicks in flawlessly.

Connecting the Switch to the Relay Control Circuit

The connection from the switch to the relay control circuit is made with precise soldering and secure wiring, ensuring every signal flows clearly. Skilled engineers apply a straightforward method that guarantees a reliable trigger for the horn every time. This setup offers a practical solution that meets rigorous industrial needs with a simple, down-to-earth approach.

Routing Wires Safely and Securely

Engineers route wires with care to avoid accidental shorts and damaged circuits. They gently secure each connection so that every push button horn reaps solid, reliable performance in the field.

Diagnosing Problems With Your Car Horn Switch

Engineers check the horn fuse, test the relay, inspect switch contacts, verify wiring, and note any clock spring issues. Each step helps pinpoint why the car horn might misfire. This troubleshooting guides like a friendly manual, offering simple steps to follow for clear, reliable results.

Contact Langir for Custom Car Horn Switches

Checking the Horn Fuse First

Engineers know that checking the horn fuse first is a smart move when the car horn isn’t sounding like it should. They find that a simple look at the fuse can save time and stress by pinpointing a common failure, giving confidence to anyone troubleshooting a faulty horn switch. This practical step is essential for maintaining reliable performance in push button switch systems.

Testing the Horn Relay Operation

Engineers check the horn relay by applying a voltage test to see if it promptly channels power to the horn unit, and they often use a multimeter to verify the switch’s action, ensuring that every tick of the circuit meets performance standards.

Inspecting Horn Switch Contacts for Wear or Damage

Inspecting horn switch contacts is a straightforward process that can pinpoint wear or damage causing your car horn to misfire. Engineers recommend a close look at the contacts using a multimeter, ensuring that every connection is clean and secure for reliable performance. This practical check helps detect issues early, saving time and avoiding larger electrical troubles down the road.

Verifying Wiring Continuity to and From the Switch

Engineers verify the wiring continuity to pinpoint any breaks or loose connections that might be interrupting the car horn’s signal. They use simple multimeter tests to quickly check each connection point:

- Test switch terminals

- Inspect solder joints

- Confirm ground stability

Symptoms of a Failing Clock Spring Affecting the Horn

Engineers note that a failing clock spring can cause inconsistent horn responses and noticeable delays, making the honk sound weak or intermittent. This issue often appears after prolonged use, and a quick test with a multimeter usually reveals erratic wiring and poor contact in the clock spring assembly. The practical fix involves inspecting and replacing the clock spring to restore clear, reliable horn performance.

How Does a Car Horn Switch Work | FAQs

What makes the basic car horn circuit work?

A basic car horn circuit sends electrical energy from the battery through a relay that triggers the horn, which converts energy into sound using an electromagnet setup.

How does the horn button mechanism function?

The horn button mechanism uses a tiny switch that, when pressed, sends an electric signal for a clear alert. Langir’s reliable push buttons ensure fast, dependable performance for all applications.

What happens electrically when the horn activates?

When the horn activates, an electric signal flows through the circuit, triggering a rapid power surge that opens the switch, which in turn sends energy to produce sound through the horn.

Which types of automotive horn switches are common?

Common automotive horn switches include momentary pressure-contact, push button, toggle, and multi-function versions integrating extra controls; Langir offers reliable, bulk orders with low MOQs and fast turnaround for these key automotive components.

How can wiring issues with a horn switch be solved?

Inspect the wiring at connection points, ensure tight, secure stops, and test continuity. Replace any frayed cords with quality materials for a trusted fix. If issues persist, consult the manufacturer expert for reliable support.

EN

EN