Curious how an LED push button switch delivers both clear illumination and dependable on-off control in demanding industrial environments? This comprehensive guide demystifies complex wiring and technical specifications, detailing precisely how these electromechanical devices function, the diverse varieties available, and their critical roles across manufacturing, automotive, and medical sectors. You will gain insight into:

- The core components and integrated circuitry enabling LED feedback and switching action.

- Key distinctions among momentary, latching, anti-vandal, waterproof, and tactile designs.

- Optimal practices for wiring 2- to 5-pin configurations across various voltage ratings.

- Material selections, IP/IK ratings, and mechanical life factors crucial for long-term durability.

- Real-world industrial applications, Langir’s customization services, and streamlined bulk ordering processes.

By the conclusion of this guide, you will possess a thorough understanding of LED push button switch operation and how Langir’s high-IP, customizable solutions support large-volume procurement for industrial OEMs.

Understanding the LED Push Button Switch: Function and Core Principles

An LED push button switch is a precision electromechanical control device designed to complete or interrupt an electrical circuit while simultaneously illuminating an integrated LED for immediate visual feedback. This dual functionality enhances operational clarity within control panels and machinery interfaces by seamlessly merging switching contacts with a low-power indicator light. In industrial automation, this mechanism ensures clear status signaling, allowing operators to quickly ascertain a machine’s state, even in challenging low-light conditions. Grasping its fundamental operation is essential for exploring component interactions and effective wiring strategies.

Get a quote for custom LED push button switches from Langir

Get a quote for custom LED push button switches from Langir

Key Components of an LED Push Button Switch

These integral parts collaborate to ensure that pressing the actuator closes the contacts, facilitating current flow through both the load circuit and the LED, with the spring promptly resetting the mechanism. Recognizing the purpose of each component reveals the seamless integration of illumination and switching.

Exploring LED Push Button Switch Components

LED push button switches integrate mechanical actuation with illumination through key components such as the actuator, contacts, LED, spring, and housing. When the actuator is pressed, the contacts close, allowing current to flow through both the load circuit and the LED, thereby providing clear visual feedback of the switch’s operational state.

Langir, “How Do LED Push Button Switches Work: Mechanism, Types, and Industrial Applications”

This citation supports the detailed description of the components and their functional roles within an LED push button switch, as presented in this article.

Electrical Circuitry: Enabling LED Illumination and Switching

The sophisticated integrated circuit within an LED push button switch establishes two distinct electrical paths—one dedicated to the load and another for the LED indicator. When the actuator is engaged:

- The switch contacts close, completing the primary load circuit to power the machinery or signal.

- Concurrently, a resistor-protected branch allows current to flow through the LED, initiating illumination.

- Upon release, the spring mechanism forces the contacts open, simultaneously interrupting both circuits.

This intelligent dual-circuit design ensures that the LED illuminates only when the switch is actively engaged, providing immediate and unambiguous feedback. Precise resistor sizing and voltage matching are critical to guarantee stable illumination without compromising the main load circuit.

Momentary vs. Latching Switch Mechanisms: Key Distinctions

A momentary LED push button switch completes its circuit solely while actively pressed, instantly reverting to an open state upon release. In contrast, a latching switch toggles its internal contacts with the initial press and maintains that state until pressed again, effectively locking its position.

- Momentary switches are ideal for applications requiring transient control, such as doorbells or emergency stop functions.

- Latching switches are suited for persistent on/off functions where the switch must remain in a set position, like powering a conveyor belt system.

A clear understanding of these operational styles is crucial for selecting the appropriate mechanism to meet specific control requirements and user interaction needs.

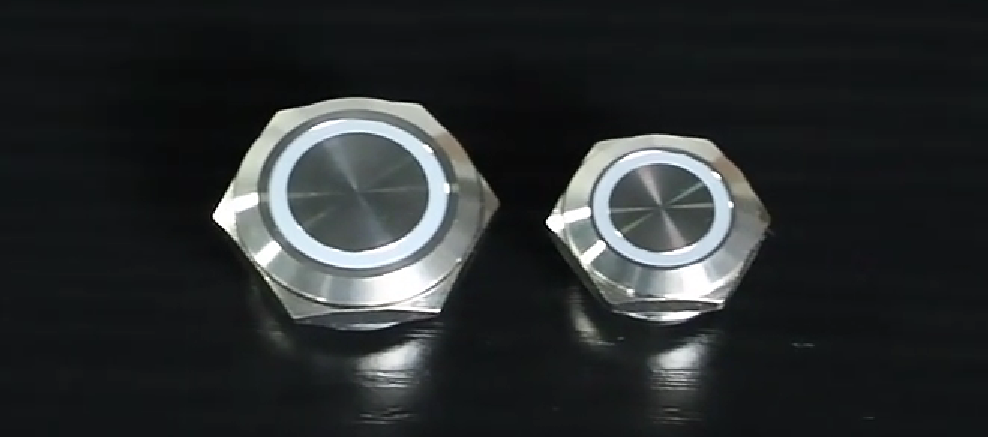

Common Types of LED Push Button Switches and Their Variations

LED push button switches are available in diverse designs, each meticulously engineered for distinct industrial conditions. From robust anti-vandal models to compact tactile versions, these variants expertly balance durability, feedback style, and installation form factor. Recognizing their functional differences is key to making optimal choices for your application’s specific environment and performance demands.

Operation of Momentary, Latching, and Anti-Vandal Switches

Each type’s unique mechanical design and sealing level dictate its suitability for environments ranging from sterile cleanrooms to high-impact public installations.

Features of Waterproof and Tactile LED Push Button Switches

Waterproof switches achieve superior protection, often up to IP67/IP68 ratings, through meticulously sealed housing, contacts, and LED components, effectively preventing the ingress of dust and water. Tactile switches deliver a distinct “click” feedback via a metal dome or snap-action mechanism, providing users with tangible confirmation of activation. Together, these features ensure reliable operation and enhance user confidence, particularly in harsh or wet industrial conditions.

Impact of Illumination Type on Switch Function and Application

Selecting the appropriate illumination style significantly enhances both readability and diagnostic clarity within any industrial interface.

Wiring and Installation of LED Push Button Switches

Correct wiring is paramount for ensuring stable LED performance and the safe switching of electrical loads. Whether utilizing a straightforward 2-pin design or a more versatile 5-pin configuration, adhering to precise diagrams and respecting all voltage/current ratings is essential for error-free installation and long-term reliability.

Get a quote for custom LED push button switches from Langir

Common Wiring Configurations for LED Push Button Switches

LED push button switches typically employ the following terminal setups:

- 2-Pin: Dedicated solely to LED illumination, without switching contacts.

- 3-Pin: Integrates an LED with a single-pole single-throw (SPST) switch.

- 4-Pin: Features an LED and SPDT contacts for comprehensive on/off control and indication.

- 5-Pin: Provides dual circuits with SPDT contacts plus an independent LED circuit.

Wiring Configurations and Voltage Considerations

LED push button switches are available in various wiring configurations, including 2-pin, 3-pin, 4-pin, and 5-pin setups, which directly influence how the LED and the primary load circuit are powered. Adhering to specified voltage and current ratings is critical, as these dictate the appropriate LED voltage branches, necessary resistors, and contact sizes required to prevent damage and ensure safe, reliable operation.

Langir, “How Do LED Push Button Switches Work: Mechanism, Types, and Industrial Applications”

This citation supports the discussion on various wiring configurations and underscores the critical importance of voltage and current ratings for the safe and effective deployment of LED push button switches, as detailed in this article.

Influence of Voltage and Current Ratings on Wiring Choices

Switches rated for 12 V or 24 V DC necessitate matching LED voltage branches and appropriate resistors. Industrial variants designed for up to 110 V AC or 220 V AC require higher-voltage LEDs or external resistors for safe operation. Current ratings (e.g., 5 A, 10 A, 21 A) directly determine the required contact size and wiring gauge. Always verify that your supply voltage precisely aligns with the switch’s voltageRequirement to prevent LED burnout or contact welding, ensuring optimal performance and longevity.

Step-by-Step Wiring Instructions for Illuminated Push Button Switches

Follow these precise steps for wiring a typical 4-pin SPDT plus LED switch:

- Disconnect all power to the circuit and confirm zero voltage using a multimeter.

- Accurately identify pins: common (COM), normally open (NO), normally closed (NC), LED positive (+), and LED negative (–).

- Connect the load wire to the COM terminal and the device wire to the NO terminal.

- Attach the LED + terminal to the positive power supply, ensuring it passes through a properly sized resistor.

- Connect the LED – terminal to the circuit ground.

- Secure all terminals firmly using a torque screwdriver to prevent loose connections.

- Restore power to the circuit and press the button to verify correct load activation and LED illumination.

Adhering to these steps minimizes wiring errors and ensures the LED indicator precisely synchronizes with the switch’s operational state.

Materials and Durability Features of Industrial LED Push Button Switches

Industrial-grade switches must exhibit exceptional resistance to corrosion, impact, and environmental ingress to withstand harsh operating conditions. The selection of housing materials and adherence to protective ratings are fundamental to achieving long-term reliability under frequent cycling and extreme environments.

Impact of Stainless Steel, Brass, and Plastic Materials on Switch Longevity

Strategic material selection ensures the switch’s endurance precisely aligns with anticipated environmental stresses and critical compliance requirements.

IP and IK Ratings: Importance for Industrial Switches

An IP rating (Ingress Protection) precisely quantifies a switch’s sealing effectiveness against dust and water (e.g., IP65, IP67, IP68). An IK rating measures its resistance to mechanical impact (e.g., IK09, IK10). High IP/IK ratings are crucial as they guarantee a switch will continue to function reliably even after exposure to water jets or significant mechanical shocks—a critical requirement for outdoor machinery and public-facing installations.

Mechanical Life and Switch Reliability in Industrial Settings

Mechanical life specifies the total number of actuations a switch can endure before potential failure—typically ranging from 1 million to 5 million cycles for industrial-grade switches. A longer cycle life directly translates to reduced maintenance downtime and lower replacement costs in high-usage applications, such as assembly-line controls, significantly enhancing operational efficiency.

Industrial Applications of LED Push Button Switches

LED push button switches are instrumental in enhancing operational clarity and safety across a diverse range of industrial sectors. Their integrated illumination and robust design make them indispensable wherever machine status must be monitored at a glance, ensuring efficient and secure operations.

Get a quote for custom LED push button switches from Langir

Enhancing Industrial Control Panels with LED Push Button Switches

By providing clear, immediate visual cues, these advanced switches significantly reduce operator error and accelerate fault diagnosis. Illuminated legends and intuitive color-coded indications streamline process monitoring and empower maintenance teams to swiftly identify issues without the need to consult separate indicator lights, thereby boosting productivity.

Typical Applications in Automotive, Medical, and Machinery Industries

Common and critical use cases include:

- Automotive assembly lines: Precision process start/stop controls featuring clear ring illumination.

- Medical devices: Highly reliable tactile switches for user interfaces in sterile and sensitive environments.

- Heavy machinery: Robust anti-vandal, sealed switches deployed on outdoor and high-impact equipment.

These examples powerfully illustrate the switches’ exceptional versatility across both high-precision and high-impact industrial settings.

Case Studies: Demonstrating Efficiency and Safety Benefits

In a notable manufacturing plant case study, the integration of bi-color LED push button switches resulted in a remarkable 30 percent reduction in troubleshooting time. Similarly, a leading medical equipment supplier reported zero switch-related failures over 18 months of continuous operation—unequivocally proving that robust illumination and superior sealing directly translate into measurable productivity gains and enhanced safety.

Customization and Bulk Ordering of LED Push Button Switches

Industrial clients frequently require tailored solutions, including custom actuator shapes, specific illumination colors, precise engravings, and optimized minimum quantities for cost efficiency. Langir’s streamlined bulk-order process addresses these needs comprehensively, supported by expert engineering assistance and rapid prototyping capabilities.

Available Customization Options for LED Push Button Switches

Clients can precisely specify the following parameters:

- Actuator color, shape, and custom engraving for brand consistency and functional clarity.

- LED wavelength or bi-color combinations to convey specific operational states.

- Housing material and finish to match environmental demands and aesthetic requirements.

- Contact configuration and precise voltage ratings to integrate seamlessly with existing systems.

These extensive choices ensure that switches align perfectly with branding guidelines, stringent safety standards, and specific functional requirements.

Langir’s Facilitation of Bulk Orders and Industrial Client Needs

Langir provides a clear and efficient procurement path: beginning with expert engineering consultation to define precise specifications, followed by sample approval, and culminating in production runs starting from modest minimum order quantities. For bespoke designs or high-volume requirements, we encourage you to contact us directly to request a detailed quote and receive technical guidance perfectly aligned with your project timeline.

Essential Design Considerations for Industrial Clients

When conceptualizing your custom switch assembly, it is crucial to account for the following critical factors:

- Electrical load and duty cycle to ensure optimal performance and longevity.

- Environmental sealing (IP/IK ratings) for protection against dust, water, and impact.

- Mounting panel thickness and precise cut-out dimensions for seamless integration.

- Required regulatory certifications (CE, RoHS, TUV) to ensure compliance.

Proactively balancing these factors during the early design phase ensures a seamless transition from prototype to full-scale production.

Common Troubleshooting Tips for LED Push Button Switch Issues

Even the most rugged industrial switches can occasionally encounter issues such as LED burnout, miswiring, or contact wear. A systematic diagnostic approach is essential to quickly reduce downtime and prevent recurring failures, ensuring continuous operational reliability.

Diagnosing and Fixing LED Failures in Push Button Switches

Begin by verifying the supply voltage at the LED terminals. Next, meticulously inspect the resistor path for any open circuits. If voltage is present but illumination fails, proceed to replace the LED module. Ensuring correct polarity and appropriate resistor sizing will restore reliable indicator performance.

Typical Wiring Errors and Their Correction

Common wiring mistakes include reversed LED polarity, loose terminal connections, and inadvertently mixing up Normally Open (NO) and Normally Closed (NC) contacts. Correct these errors by clearly labeling all wires, utilizing torque-controlled screwdrivers for secure connections, and diligently referencing the switch wiring diagram prior to applying power.

Using Continuity Testers to Check Switch Circuit Integrity

With all power disconnected, place the probes of a continuity tester on the Common (COM) and either the Normally Open (NO) or Normally Closed (NC) terminals. Actuate the switch: continuity should be observed between COM and NO when pressed, and between COM and NC when released. This straightforward test effectively confirms contact functionality before re-energizing the circuit, ensuring safety and proper operation.

LED push button switches seamlessly merge efficient illumination with dependable mechanical control, significantly boosting safety, clarity, and uptime in demanding industrial environments. By thoroughly understanding their components, diverse types, precise wiring methods, and extensive customization possibilities, you can confidently specify the exact solution your project requires. Ready to streamline your next control panel or machinery interface with high-quality, bulk-order LED switches? Reach out to Langir’s expert engineering team today to explore your options and request tailored quotes designed to meet your specific needs.

EN

EN