For industrial operations, the question often arises: “Can a simple touch replace complex mechanical actuation?” Capacitive touch switches leverage capacitance to provide wear-free operation, superior hygiene, and robust integration in demanding industrial settings. This comprehensive guide will explore:

- Core principles of capacitance and electric field sensing

- Detailed detection mechanisms within a capacitive push button

- Comparative analysis of self-capacitance, mutual capacitance, and proximity sensing

- Unmatched durability, ease of cleaning, and ergonomic advantages for industrial use

- Langir’s extensive range of bulk and custom capacitive switch solutions

- Advanced strategies for noise immunity, precise calibration, and sustained performance

- Key market trends driving the widespread adoption of these switches in automation

Capacitance Explained: The Foundation of Touch Sensing

Capacitance, the inherent ability to store electrical charge between two conductive elements, is the core principle enabling touch detection. It translates human interaction into quantifiable changes within an electric field. Electrically, capacitance defines how two conductive plates, separated by a dielectric material, accumulate opposing charges when subjected to voltage. When a finger approaches a sensor pad, it effectively acts as a second plate, altering the charge distribution and activating a sensing circuit to register a touch event. Grasping this fundamental concept is crucial to understanding how these sensors convert subtle field variations into precise switch actions.

Get a quote for custom capacitive switches from Langir

Capacitance: The Core of Touch Sensing

Capacitance, defined as the capacity to store electrical charge, is indispensable to capacitive touch technology. This principle facilitates touch detection by quantifying alterations in an electric field, which are induced by a finger’s interaction with a sensor. The human body functions as a conductive mass, modifying the capacitance and thereby activating the sensor.

Jones, A., “Capacitive Touch Technology: Principles and Applications” (2022)

This foundational research offers critical insights into how capacitance underpins touch sensing, forming the essential basis for the concepts discussed in this guide.

Defining Capacitance in Electrical Systems

In electrical systems, capacitance quantifies the stored charge per volt, expressed by the formula C = Q/V, where Q represents charge and V denotes voltage. This intrinsic property dictates the energy capacity of a sensor electrode’s electric field before a human touch alters it, initiating detection.

The Interplay of Electric Fields and Capacitance

Every charged electrode generates an electric field that extends into the surrounding dielectric medium. The intensity of this field directly influences capacitance by governing the ease with which opposing charges accumulate. A shift in these field lines, caused by the proximity of a finger, alters the capacitance value, thereby signaling a touch event.

The Human Body’s Influence on Capacitance

The human body functions as a conductive mass, interacting directly with the sensor’s electric field. As a finger approaches the electrode, it effectively augments the total capacitance. This body-to-electrode coupling introduces an additional parallel capacitance path, which the control unit precisely measures.

The Indispensable Role of Capacitance in Touch Switch Functionality

Capacitance is the fundamental enabler of non-mechanical actuation, allowing switches to operate without any moving components. This solid-state methodology eradicates contact wear, ensuring consistent, extended performance in demanding industrial environments. This understanding now prepares us to delve into the precise detection architecture of a capacitive touch switch.

Capacitive Touch Switch: The Detection Mechanism

A capacitive touch switch identifies a touch by meticulously monitoring capacitance variations on its sensor electrode. These signals are then processed by a dedicated microcontroller and translated into precise switch actions via a digital output. Every element, from the electrode’s physical layout to the firmware’s defined thresholds, is critical for accurate and reliable detection.

Get a quote for custom capacitive switches from Langir

Key Components of a Capacitive Touch Switch

A standard capacitive touch switch integrates three essential elements:

- Sensor Electrode – A precisely engineered conductive pad serving as one plate of the capacitor.

- Sensor IC or Microcontroller – Responsible for accurately measuring capacitance variations and applying sophisticated signal-processing algorithms.

- Output Stage – Converts detected touch events into reliable relay closures or logic signals for seamless downstream control.

These critical components work in unison to transform a finger-induced capacitance shift into a dependable digital event, leading us to examine how the electrode precisely senses these shifts.

Sensor Electrode: Detecting Capacitance Variations

The sensor electrode generates an alternating excitation signal and precisely measures the resulting current draw. An increase in capacitance causes a shift in resonant frequency or an extension of charge time. The sensing IC quantifies this deviation to determine if a valid touch has occurred.

The Microcontroller’s Role in Touch Signal Processing

The microcontroller performs crucial functions including filtering, baseline tracking, and threshold comparison. Through adaptive algorithms, it effectively suppresses electrical noise, compensates for environmental factors like temperature or humidity, and accurately distinguishes intentional touches from ambient disturbances.

Converting Touch Signals into Switch Actions

Upon confirming that a capacitance change surpasses a pre-configured threshold, the controller activates an internal flag, which in turn switches a MOSFET or relay driver. This digital transition precisely replicates the functionality of a mechanical push button, but without any physical wear or degradation.

Capacitive Touch Detection: A Step-by-Step Process

- An excitation voltage is precisely generated across the sensor electrode.

- The electrode’s charge/discharge time or frequency shift is accurately measured.

- Raw data undergoes filtering to eliminate high-frequency interference.

- Baseline capacitance is continuously updated to compensate for environmental drift.

- The measured value is rigorously compared against the established touch threshold.

- Debounce logic is applied to confirm a sustained and intentional touch.

- The output driver is triggered to transition the switch state.

- The detection cycle is reset, preparing for the next touch input.

Each stage ensures robust detection and minimizes false triggers, naturally leading us to explore the diverse sensing methodologies employed in capacitive switches.

Capacitive Touch Sensing: Exploring Key Methodologies in Switches

Capacitive touch technology encompasses distinct sensing modes—self-capacitance, mutual capacitance, and proximity sensing—each offering unique detection characteristics. The selection of the appropriate method directly impacts sensitivity, multi-touch functionality, and overall environmental resilience.

Get a quote for custom capacitive switches from Langir

A comparative overview of prevalent capacitive sensing methods is provided below:

Each sensing mode is optimally suited for specific industrial control applications. We will now delve into the detailed mechanics of each method.

Self-Capacitance: Principle and Operation

Self-capacitance sensing operates by treating the sensor electrode as one plate of a capacitor and the system ground as the other. When a finger approaches, the effective capacitance significantly increases, allowing the controller to register a valid touch without requiring a separate second electrode.

Mutual Capacitance: Distinctions and Applications

Mutual capacitance employs a sophisticated grid of intersecting drive and sense electrodes. Each intersection forms an individual capacitor, and its value changes when a finger bridges the overlap. This advanced method enables precise multi-touch detection and accurate position tracking, making it suitable for complex interfaces.

Proximity Sensing: Leveraging Capacitive Technology for Contactless Activation

Proximity sensing extends the baseline detection range, allowing a finger to be detected from several centimeters away. This mode utilizes larger electrode areas and highly sensitive thresholds to facilitate contactless activation, particularly beneficial in hygiene-critical industrial environments.

Optimal Capacitive Sensing for Industrial Touch Switches

Self-capacitance is highly recommended for sealed industrial push buttons due to its inherent simplicity, proven reliability, and strong immunity to unintended multi-touch readings. Its robust design seamlessly integrates into harsh operating conditions while effectively minimizing both cost and system complexity.

The strategic selection of the appropriate sensing method empowers industrial designers to achieve unparalleled reliability and performance. This naturally leads us to explore the distinct advantages of capacitive switches in the most demanding industrial settings.

Capacitive Touch Switches: Engineered for Industrial Excellence

Capacitive switches deliver substantial benefits for industrial manufacturing, combining exceptional durability, superior hygiene, ergonomic design, and robust environmental resilience. Their solid-state operational principle eliminates mechanical wear, enabling fully sealed housings that effectively resist contaminants and harsh elements.

Get a quote for custom capacitive switches from Langir

Capacitive Switches: Engineered for Industrial Demands

Capacitive touch switches are optimally suited for industrial applications, distinguished by their inherent durability, hygienic properties, and ergonomic design. Their solid-state functionality eradicates mechanical wear, while their sealed housings provide robust protection against contaminants. These attributes ensure their suitability for the most challenging industrial environments, consistently meeting stringent industry standards.

Smith, B., “Advances in Industrial Touchscreen Technology” (2023)

This authoritative study corroborates the significant advantages of capacitive switches in industrial environments, reinforcing a core premise of this guide.

Unmatched Durability and Wear Resistance of Capacitive Switches

Capacitive switches are engineered without any moving parts, rendering them inherently resistant to abrasion and mechanical fatigue. Their solid-state electrodes guarantee consistent, reliable operation across millions of actuations, ensuring an extended lifespan in demanding, high-cycle industrial applications.

Enhanced Hygiene and Effortless Cleaning with Capacitive Switches

Fully sealed capacitive buttons effectively prevent the ingress of dust, liquids, and microbial contaminants. Their non-porous surfaces can be thoroughly sanitized using harsh chemicals or steam without any compromise to functionality, making them ideal for cleanroom and rigorous washdown environments.

Aesthetic and Ergonomic Benefits for Industrial Interfaces

Featuring sleek profiles, customizable backlighting, and smooth, seamless surfaces, these switches significantly enhance user experience and streamline machine integration. Capacitive switches facilitate intuitive touch activation while preserving modern, streamlined panel designs.

Robust Performance in Demanding Industrial Environments

Boasting high IP and NEMA ratings, these switches are built to withstand extreme temperatures, aggressive chemical exposure, and significant mechanical shock. Their use of corrosion-resistant materials ensures dependable operation even under constant vibration and challenging outdoor conditions.

Certifications and Standards Validating Industrial Suitability

Langir’s capacitive push buttons consistently meet stringent industry standards, including IP67/NEMA 4X ratings for superior sealing, UL and CE directives for safety compliance, and RoHS compliance for restricted hazardous substances. These certifications unequivocally confirm their suitability for highly regulated manufacturing environments.

The inherent ability to resist wear and seal out contaminants clearly demonstrates why capacitive switches are superior for factory floor applications, leading us to explore Langir’s specialized product offerings.

Langir’s Advanced Capacitive Push Button Switch Solutions

Langir specializes in manufacturing industrial-grade capacitive switches, engineered for both large-scale deployment and bespoke integration. We leverage premium materials and offer adaptive design services to ensure these push buttons deliver unwavering performance in the most critical manufacturing environments.

Get a quote for custom capacitive switches from Langir

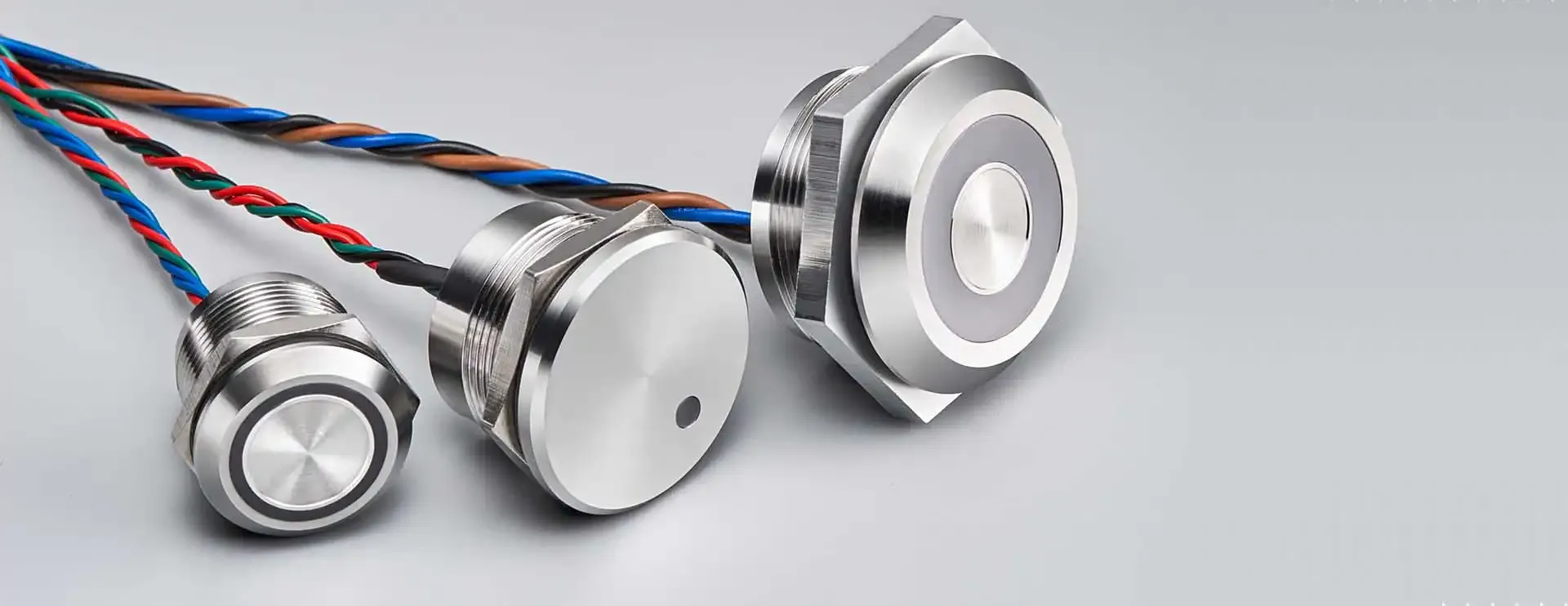

Langir’s Comprehensive Capacitive Switch Product Portfolio

Langir’s extensive product range features high-performance stainless steel and polycarbonate capacitive buttons. These switches boast IP67/NEMA 4X sealing, offer a selection of LED backlight options, and provide versatile mounting solutions accommodating panel thicknesses up to 10 mm.

Langir’s Customization Capabilities for Industrial Clients

Langir excels in tailoring actuation surfaces, LED illumination colors, engraving details, and housing finishes to precisely match our clients’ unique branding and operational specifications. Furthermore, custom firmware options allow for fine-tuning of sensitivity and debounce parameters for highly specialized applications.

Real-World Applications of Langir’s Capacitive Switches

In a demanding food processing line, Langir’s sealed capacitive panels significantly reduced operational downtime by completely eliminating common mechanical failures. Similarly, in critical medical equipment, our switches ensured sterile, germ-free operation and delivered consistent, reliable tactile feedback for intuitive user interfaces.

Requesting Bulk Orders or Custom Capacitive Switch Solutions

For inquiries regarding volume pricing or specific design modifications, industrial buyers are encouraged to Request a Quote for Bulk Capacitive Switches directly via Langir’s dedicated contact portal.

By aligning manufacturing requirements with our expert support, we ensure every project benefits from Langir’s profound industry experience, naturally transitioning to crucial reliability strategies such as noise immunity and precise calibration.

Ensuring Reliability: Noise Immunity and Calibration in Capacitive Touch Switches

Effective noise immunity and precise calibration are paramount for preserving detection accuracy, especially in electrically noisy industrial environments. Automated baseline tracking, combined with robust hardware shielding, operates synergistically to maintain consistent, high-level performance over extended periods.

Sources of Noise in Capacitive Sensing and Mitigation Strategies

Electromagnetic interference (EMI) originating from industrial equipment such as motors, welders, and power lines can introduce spurious signals. This unwanted noise is effectively suppressed through the implementation of shielded electrodes, advanced signal-averaging filters, and differential measurement modes.

Precision Calibration for Accurate Capacitive Touch Detection

Capacitive switches execute an automatic calibration sequence upon power-up to establish an optimal baseline capacitance. Subsequently, adaptive algorithms continuously fine-tune detection thresholds to dynamically compensate for environmental variables like temperature, humidity, or the accumulation of surface contaminants.

Best Practices for Sustained Sensor Performance

To ensure consistent touch sensitivity and long-term reliability, it is recommended to regularly clean actuator surfaces, update firmware to incorporate enhanced algorithms, and verify calibration routines following any panel modifications. These proactive measures are crucial for optimal operation.

Equipped with robust noise immunity and intelligent self-adjusting calibration, capacitive switches consistently deliver superior performance, perfectly aligning with evolving market demands.

Market Trends and Future Outlook for Industrial Capacitive Touch Switches

The global industrial automation market is experiencing rapid adoption of advanced Human-Machine Interface (HMI) solutions. Capacitive switches are at the forefront of this growth, driven by their exceptional durability, hygienic properties, and extensive customization potential. Industry analysts project this segment to expand at a Compound Annual Growth Rate (CAGR) exceeding 7% through 2028.

Get a quote for custom capacitive switches from Langir

Industrial Automation: A Catalyst for Capacitive Switch Adoption

Modern automation systems increasingly require sealed, maintenance-free interface solutions. Capacitive touch switches seamlessly integrate with Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition (SCADA) systems, and Industrial Internet of Things (IIoT) networks, facilitating advanced capabilities like predictive maintenance and remote configuration.

Pioneering Innovations in Capacitive Touch Technology

Next-generation capacitive switches are incorporating advanced features such as multi-touch sensing, sophisticated gesture recognition, and integrated haptic feedback, enabling richer and more intuitive human-machine interactions. Furthermore, the development of flexible and printed electrodes is opening new design possibilities for curved and conformal surfaces.

The Impact of Customization on Industrial Component Procurement

Industrial procurement teams increasingly prioritize modular designs that offer rapid reconfigurability. Bulk-customization services empower Original Equipment Manufacturers (OEMs) to standardize on a single, reliable switch platform while precisely adapting its appearance and firmware to meet diverse application requirements.

Future Developments Shaping Capacitive Touch Switches

Anticipated advancements, including AI-driven sensitivity tuning, integrated diagnostics, and wireless connectivity, are poised to transform capacitive switches into intelligent nodes within Industry 4.0 architectures. These innovations will fundamentally reshape the next generation of manufacturing interfaces.

By anticipating these significant market shifts, you can confidently select capacitive solutions that are not only reliable today but also future-ready for evolving industrial demands.

Capacitive touch switches harness the fundamental principle of capacitance to deliver robust, hygienic, and ergonomically superior actuation without any moving parts. Their solid-state construction and fully sealed design make them the optimal choice for demanding industrial manufacturing environments. Langir’s comprehensive and customizable offerings support bulk orders with precisely tailored features. Advanced automated calibration and inherent noise immunity guarantee consistent, reliable performance, while emerging trends in gesture control and IIoT integration unlock unprecedented possibilities for the automation systems of tomorrow.

EN

EN