Have you ever encountered a sleek, flat panel and pondered if its responsiveness stems from electrical charge detection rather than traditional mechanical action? Recognizing a capacitive switch involves discerning its smooth interface, non-contact sensing, and swift, durable performance, all while grasping how a simple touch alters capacitance to initiate a command. This comprehensive guide will illuminate the operational principles of capacitive switches, detail their distinctive design characteristics, provide practical testing methodologies, outline effective troubleshooting techniques, offer insightful technology comparisons, highlight crucial industrial advantages, and present Langir’s streamlined procurement and customization solutions.

Capacitive Switches: Defining the Technology and Its Operation

A capacitive switch represents an advanced electronic control mechanism engineered to detect conductive objects through variations in capacitance, ensuring rapid, dependable activation devoid of mechanical components, thereby significantly extending its operational lifespan. This sophisticated sensing technology functions by leveraging the presence or direct touch of a finger to modify the electric field surrounding a dedicated sensing electrode. A sophisticated control circuit then interprets this alteration as a precise on/off event. For industrial manufacturers, this innovation translates into robust, sealed push button switches perfectly suited for deployment in the most demanding and challenging environments.

Get a quote for custom capacitive switches from Langir

Understanding Capacitive Sensing Technology

Capacitive switches harness the principle of capacitance variation to accurately detect conductive objects, providing swift and highly reliable activation without the inherent limitations of moving parts. This technological advantage proves exceptionally valuable within industrial contexts, primarily owing to its unparalleled durability and consistent performance capabilities even when exposed to severe operational conditions.

Langir, “Unlocking the Secret: How to Identify a Capacitive Switch”

This reference offers essential foundational insights into the core operational principles of capacitive switches, forming a critical basis for the comprehensive explanation of their functionality presented within this article.

Capacitance Defined: Its Fundamental Role in Capacitive Switch Operation

Capacitance quantifies a system’s inherent capacity to accumulate and store electrical charge between two distinct conductors. Within the architecture of a capacitive switch, a dedicated sensing pad and the user’s finger collectively establish a minute capacitor, the value of which precisely alters upon the finger’s proximity. This minute yet significant shift in capacitance is meticulously detected by a sophisticated sensing circuit, which subsequently activates the switch, thereby ensuring touch detection that is both exceptionally precise and consistently repeatable.

Dissecting the Core: Essential Components of a Capacitive Switch

The reliable operation of a capacitive switch is predicated upon the seamless integration of several critical components, each meticulously engineered to collectively sense touch and accurately transmit signals:

- A precisely engineered sensing electrode, typically etched onto a PCB or flexible film layer, designed to generate a stable electric field.

- A robust insulating overlay, commonly fabricated from glass, high-grade plastic, or durable metal, providing superior protection for the internal circuitry.

- A sophisticated control circuit or Application-Specific Integrated Circuit (ASIC) dedicated to accurately measuring minute variations in capacitance.

- Optional integrated backlighting LEDs, offering clear visual indication of the switch’s operational status.

Each of these integral components plays a vital role in ensuring rapid response times, facilitating a fully sealed construction, and guaranteeing an extended electrical lifespan by completely eliminating the vulnerabilities associated with mechanical wear and traditional moving contacts.

The Activation Mechanism: How Touch or Proximity Engages a Capacitive Switch

Upon the approach of a finger to the sensing electrode, an additional charge is introduced into the electric field, resulting in a measurable increase in capacitance. The sophisticated control circuit diligently and continuously monitors this field; once the capacitance value surpasses a predetermined threshold, it precisely registers a “touch” event. Subsequently, it transmits either a switch closure signal or a digital signal to the host controller, thereby enabling seamless, contactless activation that maintains unwavering reliability, even when subjected to significant vibration or extreme temperature fluctuations.

Exploring Capacitive Sensing Modalities: Key Types Explained

Capacitive sensing technology is primarily categorized into two principal methodologies—self-capacitance and mutual-capacitance—each uniquely optimized for distinct application requirements.

Self-capacitance operates by measuring a single electrode in relation to a ground reference, whereas mutual-capacitance leverages intersecting transmit and receive electrodes to accurately discern precise multi-touch events. Crucially, both methodologies consistently provide a robust, sealed, and highly reliable interface, making them ideal for demanding industrial control applications.

Visual Cues: Distinguishing a Capacitive Switch by Sight

From a visual perspective, capacitive switches are distinctly differentiated from conventional mechanical push buttons by their inherently flat, seamless surface and the complete absence of any visible moving components. Observers will note a uniform, often elegant, glass or metal fascia, frequently enhanced with integrated LED backlighting in the form of a ring or illuminated icon. A key operational indicator is the absence of any audible click upon actuation. These deliberate design characteristics collectively ensure effortless cleaning and provide superior protection against the ingress of dust or liquids.

Get a quote for custom capacitive switches from Langir

Key Visual Attributes: Recognizing Capacitive Switch Design

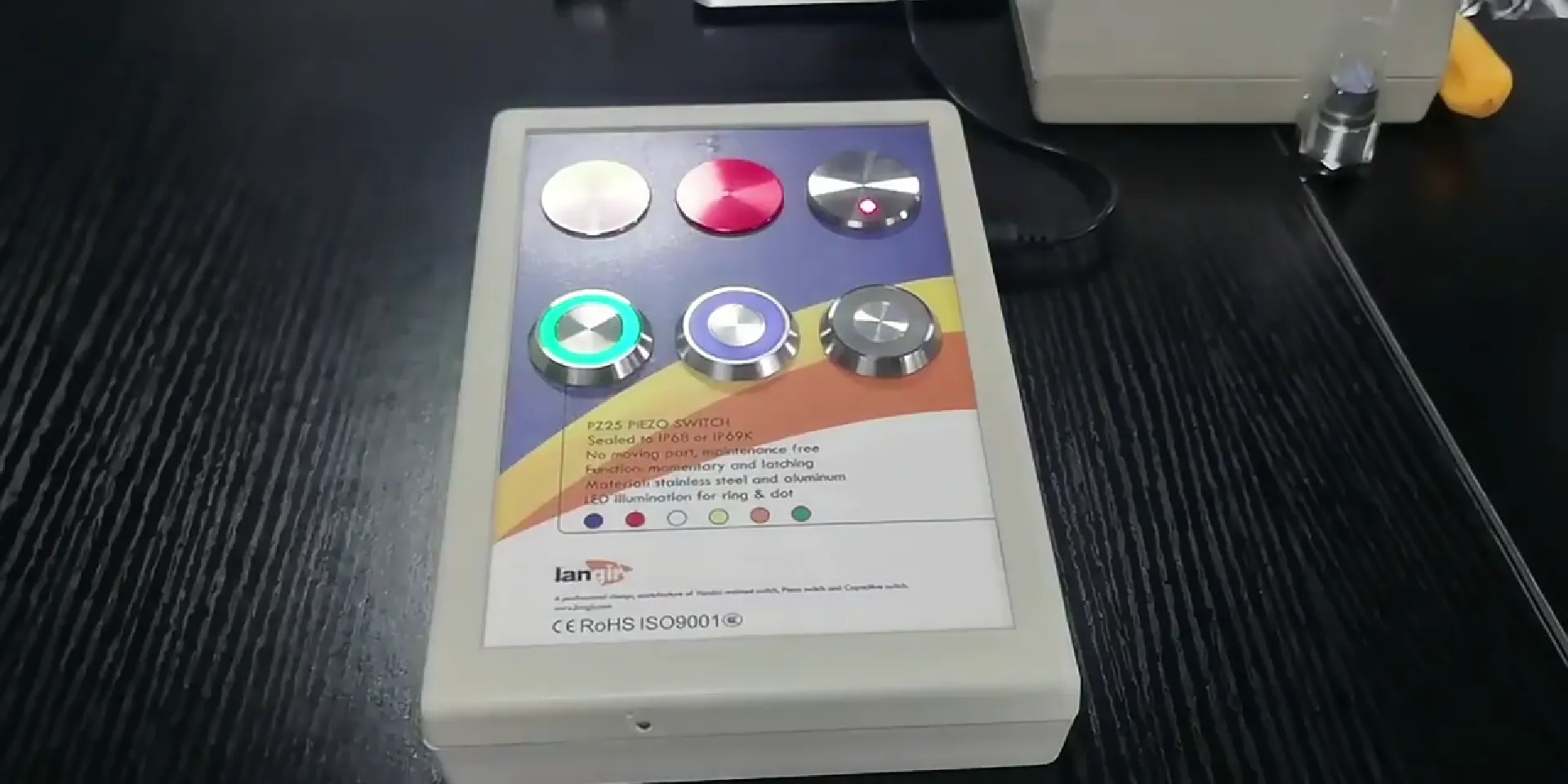

A representative capacitive push button switch consistently exhibits the following distinguishing attributes:

- A perfectly flush surface, meticulously crafted from high-grade stainless steel, durable glass, or engineered plastic.

- Seamlessly integrated LED or RGB backlighting positioned behind precisely rendered icons.

- A complete absence of visible gaps or any form of mechanical pivot mechanism.

- A uniformly smooth actuation area, often featuring clearly printed or precisely laser-etched symbols.

Visual Contrast: Capacitive vs. Mechanical Push Button Switches

In stark contrast, mechanical switches typically incorporate a raised or concave keycap, expose various moving components, and frequently provide an audible tactile click upon actuation. Conversely, capacitive buttons present as a single, uninterrupted panel entirely devoid of movable keys, a design characteristic that underscores their fully sealed, minimalist aesthetic, rendering them exceptionally well-suited for hygiene-critical or highly corrosive operational environments.

Material Science: Key Construction Materials for Capacitive Switches

Prior to specifying or evaluating control panels, it is crucial to consider the prevalent construction materials and their distinct industrial advantages:

Each of these meticulously selected materials achieves an optimal balance between robust durability, superior chemical resistance, and refined aesthetic appeal, collectively ensuring the highest standards for industry-grade touch controls.

Practical Verification: Methods for Testing Capacitive Switch Functionality

Accurately ascertaining the switch type on an installed panel frequently necessitates precise electrical measurement. The utilization of a dedicated capacitance meter or a multimeter configured in capacitance mode, coupled with careful observation of any integrated LED behavior, will definitively confirm whether the switch operates through capacitance variations as opposed to conventional mechanical closure.

Get a quote for custom capacitive switches from Langir

Precision Measurement: Utilizing a Multimeter for Capacitance Verification

- Ensure complete power disconnection and meticulously isolate the switch leads to prevent any electrical interference.

- Configure the multimeter to its dedicated capacitance measurement function.

- Carefully position the probes onto the designated electrode terminals of the switch.

- Record the initial, stable baseline capacitance value displayed on the meter.

- Gently touch the front panel of the switch with a finger and precisely observe the resulting alteration in the capacitance reading.

A distinct and measurable increase in capacitance upon tactile engagement unequivocally confirms the switch’s capacitive operational principle.

Advanced Diagnostics: Supplementary Tools for Capacitive Switch Testing

For more comprehensive and advanced diagnostic assessments, the following specialized tools may be employed:

- A high-precision oscilloscope, invaluable for visually analyzing capacitance-induced voltage shifts.

- Specialized, dedicated capacitance testers capable of logging real-time changes within the electric field.

- Controlled environmental test chambers, utilized to accurately simulate the effects of moisture or conductive contaminants on switch performance.

These sophisticated instruments provide critical insights into precise switching thresholds and operational sensitivity margins across a diverse range of environmental and operational conditions.

Interpreting Results: Confirming True Capacitive Operation

When the capacitance exhibits a distinct and measurable increase upon tactile engagement—typically a variation of a few picofarads—the switch’s integrated sensing circuit is designed to register a definitive activation. The presence of stable baseline capacitance values, coupled with consistently repeatable increases during testing, serves as unequivocal confirmation of genuine capacitive behavior, distinguishing it from mere contact closure.

Ensuring Reliability: Common Troubleshooting for Capacitive Switches

Even the most robust, sealed, and touch-activated switches can encounter environmental and integration-related challenges. Implementing a systematic diagnostic process is paramount to ensuring consistent and reliable performance throughout millions of operational cycles.

Get a quote for custom capacitive switches from Langir

Environmental Impact: Factors Influencing Capacitive Switch Performance

Potential environmental influences that can impact performance include:

- The presence of moisture or condensation, which can significantly alter the electric field’s behavior.

- Accumulation of dust or conductive debris, potentially creating unintended bridges across the switch surface.

- Interference from electrical noise, often originating from proximate high-voltage equipment.

Diagnosing Issues: Causes of Unresponsiveness or Sensitivity Problems

The most frequently encountered root causes typically involve:

- A compromised or delaminated overlay, leading to a reduction in the electric field’s strength.

- Degraded or corroded connections within the critical sensing circuit.

- Incorrectly configured calibration thresholds within the controller’s firmware.

Effective Solutions: Resolving Common Industrial Capacitive Switch Challenges

- Thoroughly clean the switch surface using appropriate alcohol wipes to meticulously remove any contaminants.

- Perform a recalibration or fine-tune the sensitivity settings directly through the switch’s integrated control module.

- Replace any worn overlays or compromised sealing gaskets to fully restore the integrity of the electric field.

Implementing these targeted measures effectively restores consistent and reliable touch detection, often precluding the necessity of replacing entire switch assemblies.

Comparative Analysis: Capacitive Switches Versus Other Switch Technologies

A thorough evaluation of switch technologies is essential for precisely aligning interface performance with specific application demands. Capacitive switches demonstrably excel in areas of durability and hygiene, whereas alternative solutions such as mechanical, resistive, and piezo switches typically provide tactile feedback or rely on pressure-based actuation.

Get a quote for custom capacitive switches from Langir

Key Distinctions: Capacitive Versus Mechanical Switch Attributes

Presented below is a comprehensive comparison of their core attributes:

Fundamentally, capacitive designs consistently provide a significantly extended operational lifespan and necessitate substantially simplified maintenance procedures within demanding industrial environments.

Comparative Performance: Capacitive Versus Resistive and Piezo Switches

Resistive switches operate by altering electrical resistance in response to applied pressure, whereas piezo elements generate a measurable voltage when subjected to mechanical force. While both technologies can facilitate sealed operation, they generally demand a higher actuation force. In contrast, capacitive switches offer a notably lighter, tool-free activation experience coupled with significantly lower power consumption, rendering them the optimal choice for applications requiring frequent and effortless interaction.

Industrial Preference: The Compelling Advantages of Capacitive Switches

Capacitive switches distinguish themselves prominently by consistently delivering:

- Exceptional water and dust resistance, fully compliant with stringent IP68 standards.

- Impeccably sanitary surfaces, making them indispensable for applications in food processing, pharmaceutical manufacturing, and medical instrumentation.

- Complete absence of mechanical wear, thereby guaranteeing consistently reliable and enduring performance.

- Highly customizable backlighting options and adjustable sensitivity levels, allowing for precise adaptation across diverse control panel requirements.

Collectively, these profound benefits significantly mitigate operational downtime and reduce maintenance expenditures, concurrently elevating the overall operator experience.

Industrial Integration: Applications and Advantages of Capacitive Switches

Get a quote for custom capacitive switches from Langir

Key Industrial Applications for Capacitive Switches

Capacitive switches are highly favored across a spectrum of industrial applications, primarily attributed to their exceptional resistance to water, dust, and extreme temperature fluctuations, consistently meeting rigorous IP68 standards. Furthermore, they provide impeccably sanitary surfaces, rendering them ideally suited for deployment in food processing, pharmaceutical, and medical environments. Their design also inherently eliminates mechanical wear, which in turn guarantees consistently reliable and enduring performance.

Langir, “Unlocking the Secret: How to Identify a Capacitive Switch”

This citation substantiates the assertions made within this article regarding the distinct advantages and specialized applications of capacitive switches, particularly within challenging industrial operational contexts.

Industry Adoption: Sectors Benefiting from Capacitive Switch Technology

- Advanced medical diagnostic devices, where impeccably cleanable and sterile surfaces are paramount.

- Sophisticated automotive dashboards and integrated infotainment control systems.

- Robust industrial machinery control panels, frequently exposed to abrasive dust and lubricating oils.

- Contemporary home automation systems, valued for their sleek, modern, and minimalist design integration.

Each of these diverse sectors derives significant advantages from the inherent benefits of sealed construction, extended operational longevity, and consistently reliable touch response provided by capacitive switches.

Performance Under Pressure: Key Benefits in Harsh Environments

Within the most demanding operational environments, capacitive switches consistently deliver:

- Superior IP67–IP68 ingress protection, safeguarding against both dust penetration and high-pressure water jets.

- Exceptional resistance to fluctuations in extreme temperatures and exposure to aggressive chemicals.

- Virtually maintenance-free operation, reliably sustained over millions of actuation cycles.

These inherent qualities collectively ensure uninterrupted operational uptime and sustained reliability across a wide array of industrial and outdoor installations.

Tailored Excellence: How Customization Elevates Capacitive Switch Performance

The process of tailoring a capacitive switch to precise specifications typically involves the meticulous selection of:

- Optimal overlay materials, including high-grade stainless steel, durable glass, or engineered plastics, chosen for their superior durability and aesthetic integration.

- Specific LED backlighting colors and illumination patterns, designed to optimize visibility and user interface clarity.

- Precise sensitivity thresholds and debounce settings, meticulously configured to align with specific operator preferences and application requirements.

This comprehensive customization capability ensures that the switch design is perfectly aligned with the most unique and demanding operational requirements of any given application.

Seamless Integration: Procuring and Customizing Capacitive Switches for Industrial Applications

Langir is dedicated to streamlining both bulk procurement and bespoke design services, meticulously tailored to fulfill the precise scale and specificity requirements of our esteemed manufacturing clientele.

Get a quote for custom capacitive switches from Langir

Streamlined Acquisition: The Process for Bulk Ordering Capacitive Switches

- Precisely define the required panel dimensions, actuation area, and specific material specifications.

- Carefully select the appropriate Ingress Protection (IP) rating, detailed electrical specifications, and desired backlighting configurations.

- Thoroughly review and formally approve all 2D/3D CAD drawings and physical prototypes.

- Confirm the projected lead time, rigorous quality control measures, and necessary certifications (including ISO 9001, RoHS compliance, and UL listings).

- Receive the final production units, complete with comprehensive batch traceability documentation and detailed testing reports.

This meticulously structured workflow is engineered to guarantee both punctual delivery and unwavering product quality.

Bespoke Engineering: Langir’s Custom Capacitive Switch Solutions

Langir’s comprehensive customization service encompasses:

- Expert material selection, offering options such as premium stainless steel, robust glass, or advanced high-grade plastics.

- Precision CNC cutting and sophisticated laser etching techniques applied to custom overlays.

- Advanced CAD-based prototyping and rapid tooling capabilities, facilitating agile and iterative design refinement.

- Meticulous firmware tuning to optimize sensitivity, response timing, and intricate backlighting patterns.

These unparalleled capabilities ensure the delivery of custom-engineered switches that integrate flawlessly and seamlessly into your existing control systems.

The Langir Advantage: Your Premier Partner for Industrial Capacitive Switches

Langir distinguishes itself by synergizing decades of unparalleled manufacturing expertise with cutting-edge, in-house capabilities, thereby offering:

- Demonstrated, robust durability, evidenced by stringent IP67–IP68 ratings and an operational lifespan exceeding 10 million cycles.

- Comprehensive, end-to-end customization services, spanning from initial conceptual design through final production.

- Rigorous quality control protocols, meticulously adhered to under the esteemed ISO 9001 international standards.

- Highly responsive and dedicated support—we invite you to request a personalized custom capacitive switch quotation to initiate your project with confidence.

In summary, capacitive switches provide an unparalleled combination of highly responsive, touch-sensitive, and virtually maintenance-free performance, achieved by precisely measuring minute shifts in capacitance without the inherent limitations of mechanical components. Their fully sealed design and exceptionally extended electrical lifespan render them the optimal solution for the most demanding industrial, medical, and automotive operational environments. Through the application of practical visual cues and straightforward electrical diagnostic methods—such as utilizing a multimeter or oscilloscope—one can definitively ascertain whether a control panel employs capacitive sensing technology. Should operational challenges emerge, routine cleaning, precise recalibration, or the strategic replacement of overlays can swiftly restore consistent and reliable functionality. By leveraging Langir’s comprehensive bulk procurement and bespoke customization services, manufacturers are empowered to acquire robust, precisely tailored touch controls, meticulously engineered for unparalleled longevity and uncompromising performance.

EN

EN