Ever wonder which switch fits your setup best? This post breaks down the differences between panel mount switches and surface mount switches. It outlines key installation tips and cost factors to help solve common headaches for folks in button switch manufacturing. Readers gain clear info and real advice to make smarter choices and ease maintenance worries.

What are Panel Mount Switches

Panel mount switches bring rugged, simple control to the table. They offer reliable signal handling and act as a solid actuator with built-in heat dissipation. This switch type shines in settings like wireless panels and industrial control. The insights below explain its functionality, key perks, and where these switches fit best.

Panel Mount Switches and Their Functionality

Panel mount switches pack a solid punch by controlling equipment in the electronics arena, keeping data and information flowing smoothly even when connected to bluetooth. Experts in manufacturing know these switches mean business, making it easy and reliable to handle control tasks in tough settings.

Key Benefits of Using Panel Mount Switches

Panel mount switches win on reliability, easily handling electric current while fitting in spots that demand a robust rotary switch or secure solder joints – they even work in setups that use a magnet to lock things in place. They keep electrical systems steady and hassle-free, making them a smart choice for anyone looking to avoid the usual technical headaches.

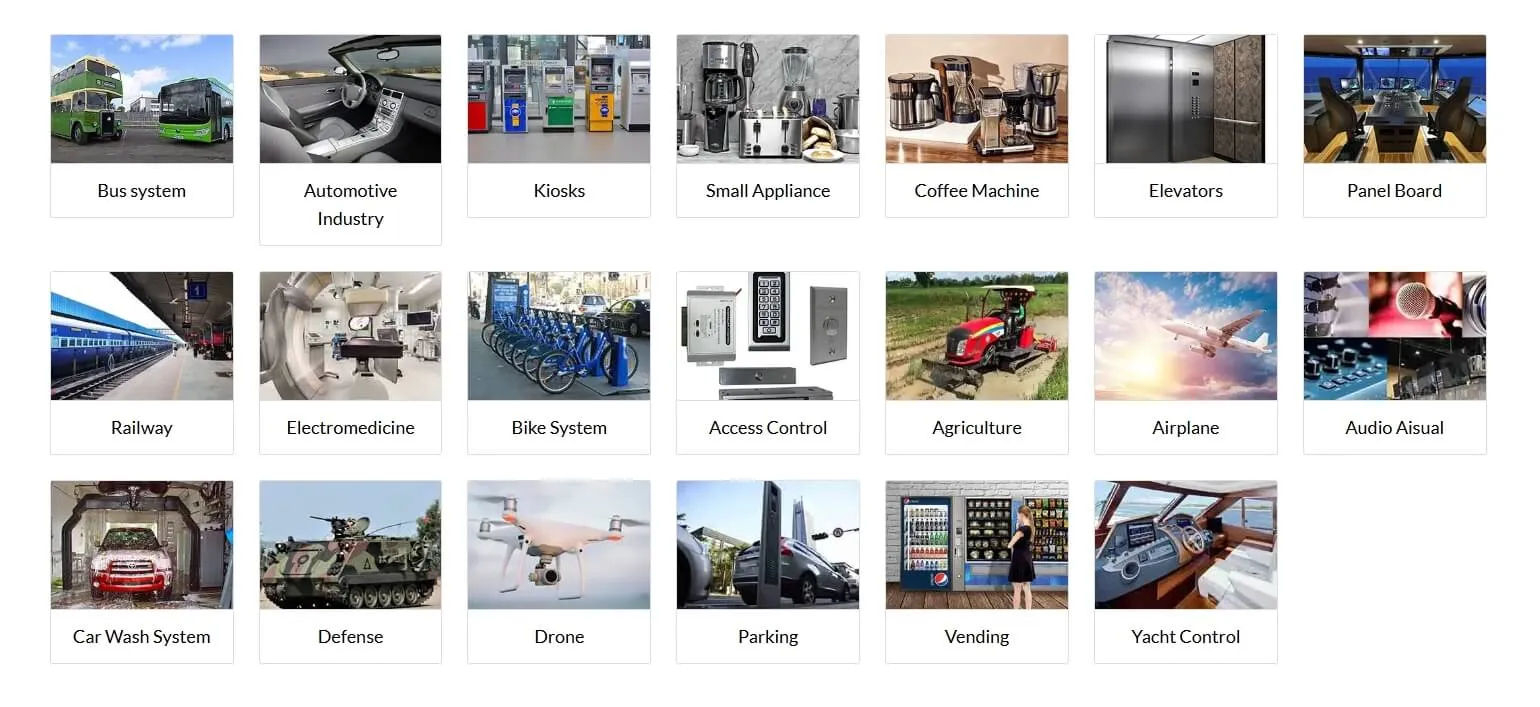

Common Applications for Panel Mount Switches

Panel mount switches are a staple in setups where durability matters, from wall-mounted panels in industrial settings to arduino projects in small labs battling constant dust. Experts note that a simple lever action meets national electrical manufacturers association standards, making these switches the go-to for reliable and straightforward control in tough environments.

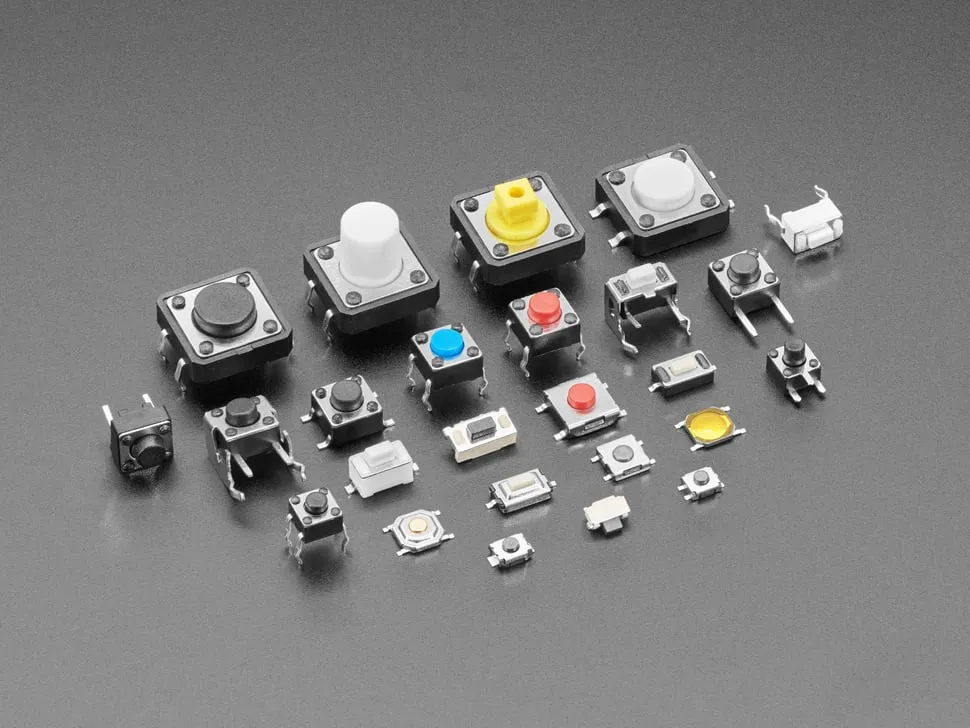

What are Surface Mount Switches

Surface mount switches offer smart, efficient work that fits in any system. They slide into setups with ease, serving in aruba panels, running smoother with a strong power supply, and boosting ethernet links. Their silver finish and robust power cord design add charm and ease. Next up, solid insights on their function, perks, and practical uses.

Surface Mount Switches and Their Mechanisms

Surface mount switches work with a simple yet solid design, featuring sturdy plastic parts that sit neatly on a switch mounting panel. They secure connections with a nut and well-organized wire, all built to meet the international electrotechnical commission’s standards for a hassle-free setup.

Advantages of Implementing Surface Mount Switches

Surface mount switches deliver smart design with top-notch power control on a printed circuit board. They run on stable voltage, use laser precision on metal components, and detail a neat alternative to panel mount switches for enhancing circuit setups:

- Sleek and compact design

- Precision assembly with laser cuts

- Reliable voltage control

- Robust construction using quality metal

Typical Applications for Surface Mount Switches

Surface mount switches are at home in setups that require a no-nonsense approach to control—think in-line with a circuit breaker, sensor setups, and even in projects fueled by a raspberry pi, all while backing gigabit ethernet connections that boost data security. They bring that reliable, straightforward performance you’d expect in industrial and DIY projects alike:

Panel Mount vs. Surface Mount Switches

Panel and surface mount switches show clear design shifts and performance traits. Panel switches often integrate a relay for robust tasks on a din rail, while surface types—like a 12v switch surface mount or smd switch—offer compact, efficient control with a trusted fuse system. The following sections detail their structure, metrics, and industry fit.

Structural Differences Between

Panel mount switches are built for tough environments and slot into an electrical enclosure with a robust design, while surface mount switches trim down the bulk for precise setups on a circuit board, meeting standards without fuss:

- Sturdy installation in heavy-duty settings

- Sleek design for space-saving projects

- Reliable connection using contact Langir guidelines

Performance Metrics

Panel mount switches hold their ground with solid metrics like consistent signal handling and stability under stress, making them fit for heavy-duty tasks. Surface mount switches, in contrast, deliver precise voltage control and compact reliability, proving they work well in tight spaces and modern industrial setups.

Suitability for Various Industries

Panel mount switches serve heavy industry and rugged setups, while surface mount switches thrive in compact, modern applications that call for easy integration; here’s a quick look at where each shines:

- Manufacturing equipment and industrial panels

- Consumer electronics and automation devices

- Laboratory testing and small-scale setups

Installation Considerations for Panel and Surface Mount Switches

Step-by-step guides for installing panel and surface mount switches help make setup a breeze. The content shares practical advice along with simple safety tips to keep everything secure. Each guide gives clear instructions so installation feels easy and no-nonsense.

Step-by-Step Installation Guide for Panel Mount Switches

The installation process kicks off with a thorough check of the mounting surface and electrical connections to ensure they match the panel mount switch’s specs. Experts secure the switch with sturdy fasteners, tighten the wiring neatly, and test the setup for reliable performance in industrial settings.

Step-by-Step Installation Guide for Surface Mount Switches

Surface mount switches are simple to set up when the steps are clear: clean the surface, line up the switch with the board, secure the wiring, and check that everything is just right:

This guide, based on hands-on know-how, helps ensure smooth installation and dependable operation for industrial projects seeking efficient control solutions.

Best Practices for Ensuring Safety During Installation

Experts stress a clear approach with proper wiring checks, secure fasteners, and routine voltage tests to make installation safe and smooth, ensuring that both panel mount and surface mount switches perform optimally. They recommend following a set of safety steps before finalizing a project setup to keep the process tight and error-free:

Maintenance and Longevity

Panel mount and surface mount switches need regular care. Next, the guide covers simple maintenance tips for front-panel models and for surface-mount types. It also flags clear signs that indicate when a switch should be replaced, so every setup keeps running smooth and worry-free.

Regular Maintenance Tips for Panel Mount Switches

Keeping panel mount switches in tip-top shape is all about a simple once-over—wipe away dust, check wiring and fasteners, and run a quick voltage test to catch any pesky issues early. Experts say a little routine maintenance can save a lot of downtime on the factory floor, making these rugged switches stick around longer.

Regular Maintenance Tips for Surface Mount Switches

Surface mount switches need a regular check, so scrubbing off dust, reviewing wiring, and running a quick voltage test keep them in peak form; these steps help avoid mishaps and save time:

Signs Indicating Replacement Needs for Each Switch Type

When a switch starts showing signs of wear, like a drop in voltage output or loose fittings, it might be time for a new one. A switch that falters or sparks unexpectedly stands out as a warning sign, urging a replacement to keep the setup sharp and reliable. Regular checks by seasoned technicians ensure these issues are caught early, saving both time and hassle in the long run.

Cost Analysis

Panel mount and surface mount switches vary in costs upfront and over time. This section breaks down purchase prices, long-term value retention, and budgeting for setup and upkeep. It offers a clear look at spending smartly while keeping control solutions both reliable and straightforward.

Initial Purchase Costs for Each Switch Type

Panel mount switches often come with a higher price tag due to their rugged build and extra parts, while surface mount switches usually cost less, making them a smart pick for tighter setups:

Long-Term Cost Considerations and Value Retention

When it comes to long-term value, panel mount and surface mount switches prove to be wise picks that hold steady over time. Experts remark that these switches maintain performance while cutting down on costly repairs and replacements, offering businesses reliable, low-maintenance solutions in the field.

Budgeting for Installation and Maintenance Expenses

Industry experts stress the need to plan every expense when setting up panel and surface mount switches, keeping budgets tight and predictable. They break down costs into installation and routine upkeep; here’s a breakdown:

Innovations and Future Trends in Switch Technologies

Panel mount and surface mount switches are shaking up control systems. Experts see emerging technologies impacting panel mount switches breathe new life into rugged setups, while future developments in surface mount switches lead to smarter designs. Industry trends affecting the choice of switch types push for better reliability and ease. Next up, clear insights on each topic reveal what’s coming next.

Emerging Technologies Impacting Panel Mount Switches

New tech is shaking things up for panel mount switches, pushing them to work smarter and last longer. Experts note that smart sensors, real-time diagnostics, and enhanced connectivity are streamlining control in tough industrial setups, offering clear benefits for maintenance and reliability:

Future Developments in Surface Mount Switches

Experts see surface mount switches getting a serious upgrade soon. New tech promises tighter precision, simpler wiring, and smarter design tweaks that cut installation hassles – paving the way for modern setups to run smoother and cost less:

Industry Trends Affecting the Choice of Switch Types

Industry trends have pushed manufacturing companies to rethink their switch choices, weighing rugged panel mount switches against sleek surface mount switches for precise control needs. Experts point out that input from real-world setups has steered this shift, offering hands-on insights into durability, compactness, and tech integration:

Effective Use of Switch Types

Real-world applications of panel mount switches play out in tough industrial settings, while successful surface mount switch setups prove they work in tight spots. Industry use cases offer clear lessons learned on keeping control systems reliable and effective. These case studies bring valuable insights from everyday manufacturing experts to light.

Real-World Applications of Panel Mount Switches

Industry experts note that panel mount switches hold up in gritty industrial setups, powering machine controls and automating heavy equipment with flawless consistency. These tough switches make maintenance look simple and stand out by cutting downtime:

Successful Implementations of Surface Mount Switches

Surface mount switches are making their mark in modern applications by offering easy setup and reliable control in tight spaces; industry experts emphasize the benefits of quick installation, steady power management, and compact design that cuts through the noise in production environments:

- Quick and simple installation

- Reliable voltage regulation

- Space-saving design perfect for modern setups

Lessons Learned From Industry Use Cases

Industry use cases show that panel mount switches and surface mount switches perform well in varied setups, easing control tasks in busy production lines and tight spaces alike. Experts point out that smart integration and consistent upkeep lower issues and boost reliability, making these switches a solid pick for everyday manufacturing work.

Panel Mount vs. Surface Mount Switches | FAQs

What are panel mount switches used for in industry?

Panel mount switches handle control tasks in industrial settings, powering circuit operations in equipment and systems to keep operations smooth and safe.

Can surface mount switches handle heavy usage?

Surface mount switches are built to handle heavy loads. Many customers trust them in industrial manufacturing because they work reliably over time, making them a strong choice for push button switch manufacturing setups under tough conditions.

What installation factors affect switch performance?

Correct mounting, proper electrical connections, ambient temperature, and moisture levels all impact push button switch performance. Secure alignment and minimized vibration boost durability and reliable operation in industrial setups.

How does maintenance impact switch longevity?

Regular maintenance preserves switch performance, preventing debris and internal wear. This routine care extends button longevity in push button switch manufacturing while reducing downtime and cost when sold in bulk.

Which costs matter for panel and surface switches?

Panel and surface switch pricing depends on raw materials, labor costs, and tooling expenses. Manufacturing scale and customization play big roles too—higher volumes lower costs, while custom orders mean extra setup and precise testing.

EN

EN