Piezoelectric switches convert mechanical force into precise, instantaneous electrical signals, offering unparalleled wear-free reliability in demanding industrial settings. While many manufacturers contend with switches prone to corrosion, jamming, or frequent replacement, piezoelectric push buttons deliver up to 50 million actuations, robust IP68 sealing, and ultra-low power consumption by eliminating traditional mechanical contacts. This comprehensive guide delves into the operational principles of piezoelectric switching, highlights its distinct advantages over mechanical and capacitive alternatives, outlines diverse real-world applications, and showcases how Langir Electric’s customizable solutions address both large-scale and specialized industrial requirements. Inside, you will explore:

- Defining the Piezoelectric Switch: The Science of Solid-State Operation

- Step-by-Step: Converting Mechanical Stress into Electrical Pulses

- Unmatched Durability, Environmental Resilience, and Hygienic Advantages

- Essential Applications: From Industrial Automation to Medical Interfaces and Wearables

- Langir Electric’s Solutions: Product Features, Customization, and Ordering Information

- Piezoelectric vs. Other Technologies: A Comparative Analysis and Market Outlook

- Optimizing Performance: Installation Best Practices and Maintenance for Longevity

Understanding Piezoelectric Switches: Core Functionality Explained

A piezoelectric switch operates as a solid-state push button, generating an electrical signal via the piezoelectric effect when mechanical pressure deforms its ceramic or crystal element. This direct conversion of mechanical energy into a voltage pulse delivers a highly reliable digital or analog output, entirely free of metal contacts. This design ensures flawless switching performance, even in the presence of moisture, dust, or significant vibration. Consider, for instance, a stainless-steel piezo button on an assembly line control panel: a simple press instantly generates a contact-free signal to activate conveyor motors.

Contact Langir for Custom Piezo Switches

The Piezoelectric Effect: The Science Powering Piezo Switches

The piezoelectric effect describes the inherent ability of specific crystals and ceramics to generate an electric charge when subjected to mechanical stress. First identified by Pierre and Jacques Curie in 1880, this fundamental phenomenon forms the operational basis of piezo switches: the application of force causes electric dipoles within the material to align, thereby generating a measurable voltage across its surfaces. This voltage is then efficiently collected by electrodes and directed to a control circuit.

Piezoelectric Effect: Material Properties and Principles

The piezoelectric effect, a discovery attributed to Pierre and Jacques Curie in 1880, defines how specific materials produce an electric charge when subjected to mechanical stress. This principle is foundational to the functionality of piezoelectric switches, where the deformation of a crystal or ceramic element under pressure directly generates an electrical voltage.

Curie, P. & Curie, J., Comptes Rendus de l’Académie des Sciences (1880)

This seminal research provides the scientific bedrock for comprehending the precise functionality of piezoelectric switches, as detailed throughout this article.

From Mechanical Stress to Electrical Signal: The Piezo Switch Trigger Mechanism

Upon actuation, the user’s press deforms the piezoelectric element, initiating the separation of internal electrical charges. Electrodes meticulously bonded to the element then capture this charge imbalance, manifesting as a distinct voltage spike. This voltage is subsequently routed through sophisticated signal conditioning electronics—typically incorporating a field-effect transistor (FET) and a resistor network—to precisely activate or deactivate the designated target circuit.

The Solid-State Advantage: How the Absence of Moving Parts Enhances Piezo Switch Performance

Unlike conventional switches, piezo switches are engineered with solid-state ceramic or crystalline elements, completely eliminating metal springs or contacts. This innovative design, devoid of mechanical wear points, eradicates issues such as contact bounce, oxidation, corrosion, and material fatigue. The result is an exceptional operational lifespan exceeding 50 million cycles, coupled with consistently reliable actuation force throughout its service life.

The Mechanics of Piezoelectric Switching

Piezoelectric switching meticulously transforms applied pressure into a precise electrical pulse via a sophisticated multi-stage process, engineered for both accuracy and enduring reliability. Each phase of this operation executes within microseconds, consistently delivering repeatable signals essential for robust industrial control systems.

Contact Langir for Custom Piezo Switches

Essential Components: The Core Elements of Piezoelectric Switching

Prior to detailing the operational sequence, let’s examine the fundamental components integral to piezoelectric switching:

These meticulously engineered components collaborate to deliver a precise solid-state “click”—devoid of tactile contacts—effectively preparing the generated charge for accurate electronic interpretation.

The Conversion Process: Transforming Mechanical Energy into Electrical Signals in Piezo Switches

- Force Application: User-applied pressure precisely deforms the piezoelectric element.

- Charge Generation: This deformation causes internal electric dipoles to align, generating opposing electrical charges on the element’s surfaces.

- Voltage Capture: Integrated electrodes efficiently capture this transient voltage.

- Pulse Conditioning: A Field-Effect Transistor (FET) and Resistor-Capacitor (RC) network then filter and precisely shape the signal to meet required logic-level thresholds.

- Circuit Activation: The conditioned electrical pulse subsequently activates a relay, logic input, or microcontroller pin, initiating the desired action.

This meticulously engineered sequence guarantees that every actuation consistently produces a precise electrical event, maintaining reliability irrespective of ambient temperature fluctuations or environmental contaminants.

Voltage and Circuit Activation: Critical Roles in Piezoelectric Switching

The magnitude of the generated voltage directly correlates with the applied force; typical raw outputs can range from 5 V up to 100 V prior to conditioning. Sophisticated electronics then precisely clamp, regulate, and translate this pulse into a safe, standardized logic-level signal (e.g., 3.3 V or 5 V) suitable for driving downstream relays or digital inputs. Rapid rise times and precisely controlled pulse widths are engineered to guarantee reliable activation of industrial PLCs, contactors, or embedded controllers.

Optimizing Performance: The Impact of Signal Duration and Pulse Shape on Piezo Switches

Signal duration and precise pulse shape are critical in determining the energized period of the target circuit and how it interprets the actuation type (e.g., momentary versus latching). Adjustable RC time constants empower designers to generate pulses ranging from a swift 10 milliseconds to several seconds. This meticulous pulse control effectively mitigates signal chatter, prevents unintended double-triggers, and optimizes power consumption, particularly crucial for low-voltage systems.

Key Advantages: Piezoelectric Switches vs. Traditional Mechanical Switches

Piezoelectric switches consistently surpass mechanical alternatives, offering superior reliability, exceptional environmental resistance, and unparalleled design flexibility. These attributes make them the optimal choice for the most demanding industrial applications.

Contact Langir for Custom Piezo Switches

Enhanced Durability and Lifespan: The Benefit of No Moving Parts

By eliminating metal springs or sliding contacts, solid-state piezo switches inherently bypass common wear-out mechanisms such as contact erosion and spring fatigue. This robust design delivers an extraordinary operational lifespan exceeding 50 million actuations—a remarkable 10 times the lifespan of most conventional mechanical push buttons—all while maintaining consistent actuation force throughout its service life.

Superior Environmental Resistance: Why Piezo Switches Excel in Harsh Conditions

Engineered with robust stainless steel or aluminum housings and certified with IP68/IP69K ratings, piezo switches provide an impenetrable barrier against water, dust, and corrosive agents. Furthermore, they are designed to flawlessly withstand extreme temperatures (from –40 °C to +75 °C) and high-vibration environments without any compromise in performance or degradation.

Vandal-Resistant Design: Ensuring Reliable Switching in Challenging Environments

Featuring robust faceplates crafted from stainless steel or heavy-duty alloys, these switches are inherently resistant to impact and tampering. The flush, tamper-proof actuator design effectively prevents leverage for prying tools and deters unauthorized disassembly—a critical advantage for public access kiosks and exposed outdoor control panels.

Energy Efficiency and High Sensitivity: Hallmarks of Piezoelectric Switching

The internal charge generation mechanism of piezo switches requires no holding current; power consumption by the electronics occurs only during the brief pulse shaping phase (mere microamps in standby). Their exceptional sensitivity allows actuation forces as low as 1 Newton to reliably trigger a switch, significantly reducing user fatigue and enabling highly responsive, touch-sensitive interface designs.

Hygienic and Easy-to-Clean: The Advantage of Sealed Piezo Switch Designs

The smooth, uninterrupted front surface of piezo switches facilitates rapid and thorough sanitization using standard cleaning agents. This critical benefit directly addresses the stringent hygiene requirements prevalent in medical and food-processing facilities, where switch assemblies are frequently exposed to harsh disinfectants.

Applications Where Piezoelectric Switching Delivers Superior Performance

Piezo switches demonstrate exceptional performance in environments where durability, robust sealing, and precise control are paramount. Their versatility spans critical sectors including industrial, medical, access control, transportation, and consumer markets.

Contact Langir for Custom Piezo Switches

Industrial Automation and Control Panels: Integrating Piezo Switches for Enhanced Performance

Within automated production lines, piezo buttons are instrumental in managing conveyors, robotic systems, and critical safety interlocks. Their extended cycle life and inherent immunity to dust and coolant sprays ensure continuous, uninterrupted operation and significantly minimize downtime.

Medical Devices and Hygienic Environments: The Indispensable Benefits of Piezo Switches

Medical imaging consoles, surgical tables, and sterilization chambers critically depend on piezo switches for their smooth, flat surfaces, which readily withstand frequent cleaning without developing micro-crevices. Their hermetic sealing effectively prevents pathogen ingress, consistently meeting rigorous IP69K hygiene standards.

Access Control and Public Systems: Why Piezo Switches Are the Ideal Choice

Vandal-resistant designs, featuring robust vandal-proof housings, provide unparalleled protection for kiosks, parking gates, and ticket dispensers. The complete absence of mechanical contacts eliminates false triggers, ensuring reliable operation even under heavy use or in challenging rainy and dusty conditions.

Automotive and Transportation: Piezo Switch Performance in Demanding Environments

Piezo buttons are engineered to withstand extreme temperature fluctuations within engine compartments and endure constant vibration in rail and marine vehicles. Their corrosion-proof housings and expansive operating temperature range (–40 °C to +85 °C) ensure the unwavering reliability of dashboards and control panels in these demanding applications.

Consumer Electronics and Wearables: The Evolving Role of Piezo Switches

Ultra-thin piezoelectric elements facilitate the integration of sleek, touchscreen-style buttons into compact devices like fitness trackers and smartwatches. Their rapid response times and minimal power consumption significantly extend battery life, all while delivering precise and satisfying haptic feedback.

Langir Electric: Excellence in Piezoelectric Switch Solutions

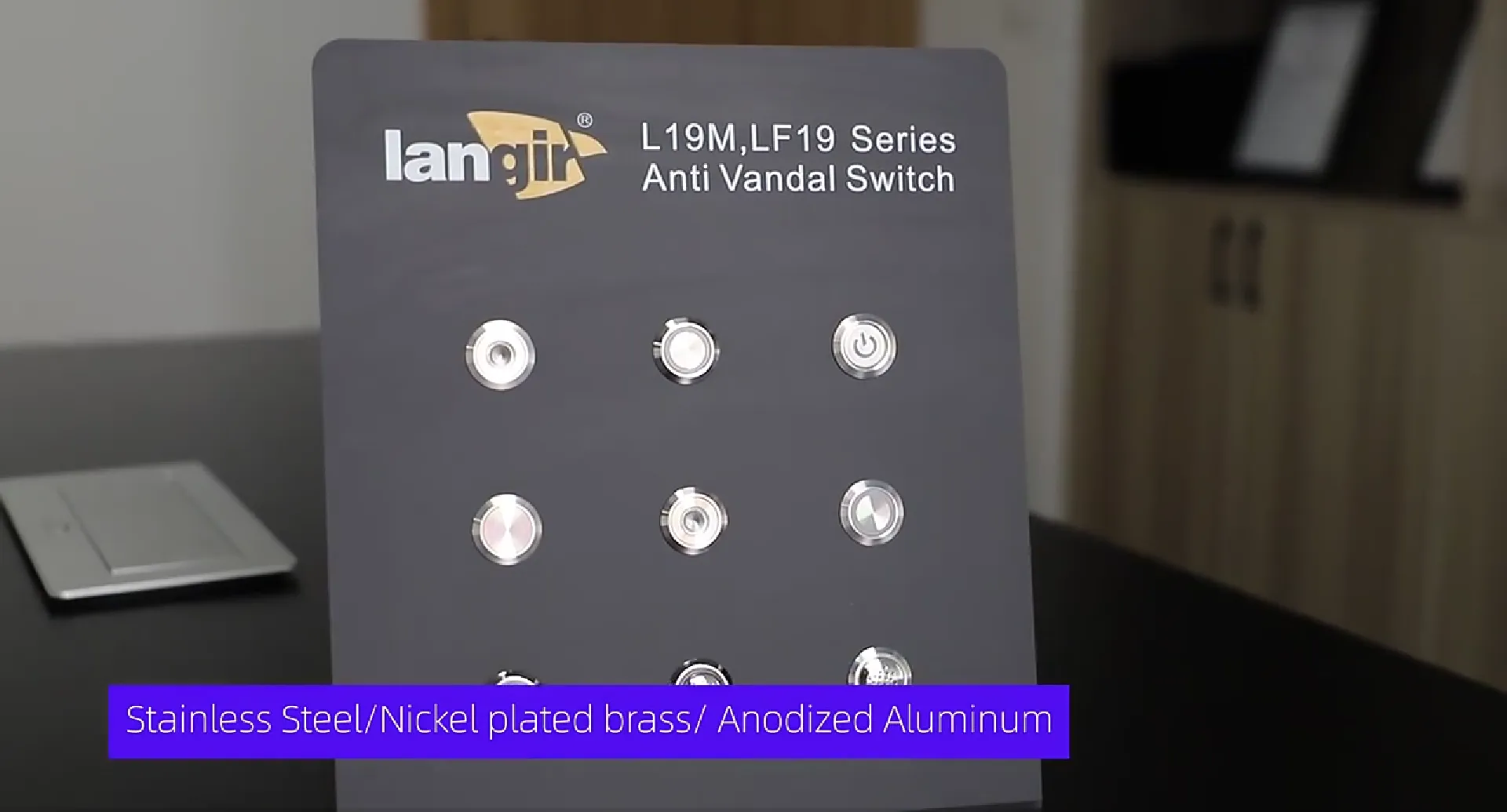

Langir Electric proudly leverages its ISO 9001-certified manufacturing processes to deliver robust, highly customizable piezoelectric switches, available in 16 mm, 19 mm, and 22 mm sizes. These solutions are meticulously engineered to meet the demands of both large-volume orders and highly specialized applications.

Contact Langir for Custom Piezo Switches

Key Features: Langir’s Advanced Piezoelectric Push Button Switches

- Sizes & Materials: Available in 16–22 mm diameters, crafted from premium stainless steel, brass, or anodized aluminum.

- Sealing & Durability: Boasting IP68/IP69K ratings, IK10 vandal resistance, and an exceptional 50 million cycle lifespan.

- Illumination Options: Customizable with ring, dot, or bespoke RGB backlighting.

- Electrical Specifications: Operates within 5–24 V DC/AC, supporting up to 1 Amp switching current.

Tailored Solutions: Langir’s Customization Capabilities for Piezo Switches

Langir’s dedicated in-house design team possesses the expertise to precisely adapt actuator shapes, finishes, illumination colors, and pulse timing. Our engineers meticulously prototype and rigorously test force thresholds and pulse widths, ensuring a perfect match for each client’s specific control logic and ergonomic requirements.

Certifications and Quality: Ensuring Langir’s Unwavering Switching Reliability

Every Langir piezoelectric switch undergoes stringent ISO 9001 quality audits and rigorous environmental testing, adhering to demanding IP68/IP69K standards. Comprehensive electrical life, salt-spray, and vibration tests are conducted to unequivocally validate their superior performance in the most challenging operational conditions.

Ordering Solutions: Requesting Bulk Orders or Custom Switch Designs

To discuss competitive volume pricing or to initiate the design of bespoke piezoelectric switches, we invite you to contact our sales team for bulk or custom solutions. Our dedicated specialists are prepared to guide you seamlessly from initial specification through to final delivery.

Piezoelectric Switching Vs Alternative Technologies

Piezoelectric switches stand out against mechanical, capacitive and Hall-effect types in lifespan, sealing and response consistency.

Contact Langir for Custom Piezo Switches

Piezoelectric vs. Mechanical Switches

Distinguishing Piezo Switches from Capacitive and Hall Effect Technologies

Capacitive buttons, which rely on finger proximity, can be prone to misfires when users wear gloves or in the presence of moisture. Hall-effect switches necessitate the integration of magnets and typically exhibit higher standby power consumption. In contrast, piezoelectric switches consistently deliver reliable actuation even with gloved hands or in liquid-present environments, all while consuming virtually zero standby current.

Strategic Selection: When Industrial Buyers Should Opt for Piezo Switches

Industrial buyers should strategically choose piezoelectric switching when extended operational life, superior environmental sealing, minimal maintenance, and robust vandal resistance are paramount. This is particularly true for demanding applications in outdoor settings, food-processing facilities, medical equipment, or high-cycle automation systems.

Emerging Trends and Outlook for Piezoelectric Switching

The piezoelectric switch market is experiencing significant expansion, driven by advancements in novel materials, innovative interface designs, and the integration of energy-harvesting functionalities.

Contact Langir for Custom Piezo Switches

Market Growth Drivers: Understanding the Expansion of the Piezo Switch Sector

Global revenues for piezo switches are projected to achieve USD 4.16 billion by 2032, demonstrating a robust 4.6 percent Compound Annual Growth Rate (CAGR). This growth is primarily propelled by the accelerating adoption of automation, increasingly stringent hygiene regulations, and a growing demand for highly tamper-proof interfaces across public and industrial sectors.

Piezoelectric Switches: Market Growth and Key Trends

The market for piezoelectric switches is currently undergoing substantial growth, primarily fueled by the increasing prevalence of automation, evolving hygiene requirements, and the critical demand for tamper-proof interface solutions. Global revenue projections indicate a significant valuation by 2032, supported by a consistent compound annual growth rate (CAGR).

Market Research Report, Piezoelectric Switch Market Analysis (2024)

This comprehensive market analysis substantiates the assertions within this article regarding the expanding market and the pivotal factors driving its sustained growth.

Technological Innovations: Advancing Piezoelectric Switching Capabilities

Emerging technological advancements include the integration of energy harvesting capabilities—allowing repeated button presses to charge supercapacitors—and the development of sophisticated hybrid sensor-switch modules capable of detecting both force and temperature for advanced smart control systems.

Miniaturization and Touchless Interfaces: Shaping Piezo Switch Adoption

Breakthroughs in micro-fabrication are yielding sub-5 mm piezoelectric elements, enabling the creation of ultra-compact controls for wearables and handheld devices. Furthermore, the development of touchless actuation modes, utilizing proximity-tuned piezo arrays, is supporting the implementation of hygiene-first designs in critical medical and automotive environments.

Global Leadership: Key Regions in Piezo Switch Manufacturing and Application

The Asia-Pacific region maintains a dominant position in production, characterized by extensive electronics manufacturing clusters in China, Japan, and South Korea. Concurrently, Europe and North America are at the forefront of innovation, particularly driving advancements in the automotive and medical sectors.

Maximizing Piezoelectric Switch Performance for Industrial Users

Proper installation and upkeep maximize switch lifespan and signal integrity in demanding industrial setups.

Contact Langir for Custom Piezo Switches

Best Practices: Wiring and Mounting Piezoelectric Switches

For panel-mount switches, precise front-to-back tightening to the specified torque (0.8–1.2 N·m) is essential, along with the use of sealed gaskets to ensure IP68 integrity. Surface-mount variants necessitate thread-lock compounds and O-ring seals for secure installation. Crucially, always route wiring meticulously away from high-voltage cables to prevent electromagnetic interference.

Electrical Connections: Ensuring Unwavering Switching Reliability

Utilize shielded, twisted-pair cables for all signal lines and ensure the metal housing is properly grounded. Implement surge-suppression diodes if the switch is driving inductive loads, and consistently verify the stability of the supply voltage to prevent any potential mis-triggers.

Maintenance Protocols: Prolonging Piezo Switch Performance and Longevity

Conduct annual inspections of all seals, clean switch surfaces exclusively with non-abrasive agents, and regularly test actuation thresholds in alignment with control logic diagnostics. Promptly replace O-rings or gaskets if any signs of wear are observed, thereby preserving the critical IP-rated integrity of the switch.

Piezoelectric switches provide unparalleled durability, robust sealing, and exceptional precision by directly converting mechanical stress into electrical signals, entirely without moving parts. Their inherent solid-state design ensures extended operational lifespans, complete immunity to harsh environmental conditions, and zero contact bounce—positioning them as the definitive switch solution across industrial automation, medical applications, public access systems, and consumer electronics. Backed by advanced customization capabilities, ISO 9001 certification, and efficient global delivery, Langir Electric is fully equipped to support both large-volume orders and highly specialized designs for any industrial challenge. Elevate the performance and reliability of your control systems with Langir’s maintenance-free piezoelectric switching solutions today.

EN

EN