In the whimsical world of small engines, the stop start switch often goes unnoticed yet plays a critical role in their operation. This simple component serves as a bridge between the user and the engine itself, allowing for a seamless start and stop experience. Essentially, when an individual flips the switch to “start,” it completes an electrical circuit that ignites the fuel-air mixture, setting the engine into motion. Conversely, when the switch is flipped to “stop,” it interrupts that circuit, effectively shutting down the engine with a satisfying finality. Understanding this balance is key for any small engine enthusiast, as it demystifies a seemingly mundane switch that wields significant power.

For the uninitiated, the stop start switch can appear as an unassuming button or lever, but its design ensures it is both intuitive and dependable. In many small engines, especially those found in lawn mowers or chainsaws, this switch is engineered for safety; it prevents accidental starts that could lead to mishaps. The clarity of its operation allows users to manage their machines easily, especially in high-stakes scenarios. Whether it’s a leisurely afternoon lawn care session or a more intensive project, knowing how the stop start switch functions empowers users, giving them confidence as they engage with their small engines. It’s not just a function; it’s part of the intimate relationship between a person and their trusty machine.

Fundamental Operation of a Small Engine Stop Start Switch

Understanding the fundamental operation of a stop start switch on small engines is key for anyone who deals with engine control. At its core, this switch directs power flow in small engine systems, controlling when the engine stops or starts. For cost-effective replacements, many operators opt for a stop start switch wholesale option available through specialized distributors. Basic operational mechanics include the conversion of electrical signals into actions that either cut off or initiate fuel and spark. When power interruption is needed, the switch disconnects the circuit, preventing engine rotation. Overall, the system ensures that engines like a tractor or lawn mower operate efficiently while also supporting diagnostics and safety protocols. For further assistance, you can always contact Langir for expert guidance.

Contact Langir for Custom Engine Stop Start Switch

Basic Operational Mechanics in Small Engine Systems

Small engines rely heavily on simple, yet reliable controls. The basic mechanism involves a push button that, when pressed, opens or closes the electrical circuit. This control integrates with components such as the alternator, starter, and ignition coil to manage the engine cycle. In everyday applications—from compressors to chainsaws—the mechanism ensures that power delivery is stable and that the engine starts or stops as needed. Its design minimizes wear and tear on the engine by preventing abrupt startups, thereby enhancing overall durability and fuel efficiency.

The Stop Start Switch Function in Power Interruption

The stop start switch plays a critical role when the system needs to halt power delivery. It quickly cuts off fuel, ignites signals, and interrupts the electrical circuit. This rapid power interruption is useful in emergency stops or when performing routine maintenance. In fields like diesel engine operation, the switch prevents unnecessary engine overrun, reducing stress on components like the crankcase and ignition system. By managing power flow smartly, the switch improves safety and protects vital engine parts from damage caused by sudden power surges.

Distinctions Between Various Switch Types in Small Engines

Not all stop start switches are created equal. Mechanical switches, for instance, have a simple on/off design, while electronic switches rely on digital signals for more accurate control. Some high-end systems integrate programmable logic controllers (PLCs) for automatic operation, improving overall responsiveness and efficiency. These distinctions affect how engines, such as those in snow blowers or motorcycles, manage start and stop phases. In many cases, opting for an electronic system can lead to better fuel consumption and fewer maintenance issues. Choosing the right type depends on the specific engine application and user needs.

Manual Operation Versus Auto Start Stop Features

Manual switches require an operator to physically press the button, making them well-suited for applications where human oversight is preferred. In contrast, auto start stop configurations use sensors to detect operating conditions such as idling or low voltage, and they automatically engage the switch. Both methods have their merits. Manual operation offers simplicity and clear user intent, while auto systems reduce operator workload and can enhance fuel efficiency by managing repetitive tasks. For versatile equipment like lawn mowers or small trucks, the choice between manual and auto operation can significantly impact performance.

Key Elements in a Small Engine Auto Start Stop Arrangement

A small engine’s auto start stop arrangement comprises several components working in concert. The primary stop start switch is the central element, usually rooted in digital or analog signal processing. Relays and solenoids work hand in hand with the switch to control large currents using small input signals. Various sensors provide information about engine temperature, voltage levels, and mechanical rotation, which are crucial in triggering the auto start stop function. For example, an alternator may signal the switch to disconnect when high electrical loads are present, thereby protecting the engine and increasing its longevity.

Contact Langir for Custom Engine Stop Start Switch

Locating the Primary Stop Start Switch Component

Locating the primary switch within the engine’s wiring harness is the first step in troubleshooting. Usually mounted on the control panel or near the engine block, this component is critical in sending the right signals to power the engine on or off. Its placement is designed for easy access during maintenance.

Understanding Relays and Solenoids Within Auto Start Stop Designs

Relays and solenoids act as intermediaries; they use small electrical currents to trigger larger switches. These components ensure that the engine’s auto start stop feature works correctly by protecting the circuitry and managing current flow.

How Sensors Activate Auto Start Stop Operations

Sensors feed real-time data into the system. For instance, low voltage or overheating conditions automatically trigger the switch, ensuring that proper engine parameters are maintained and damage is prevented.

Power Source Requirements for Auto Start Stop Functionality

Reliable power inputs from sources like batteries and alternators are essential. Without stable power, the switch might not function accurately—leading to unwanted engine shutdowns or starting issues.

Control Diagram for Small Engine Applications

A detailed control diagram shows how electrical paths are configured from the stop start switch through all engine parts. These diagrams use standard symbols to denote components like fuses, relays, and sensors. Engineers rely on these schematics for troubleshooting and ensuring correct wiring. By following the electrical paths laid out in a diagram, technicians can pinpoint faults and rectify issues without dismantling the engine extensively.

Contact Langir for Custom Engine Stop Start Switch

Standard Symbols Found in a Start Stop Motor Control Diagram

Symbols represent relays, push buttons, and even ground points. Familiarity with these helps diagnose problems quickly.

Following Electrical Paths From Switch to Engine Parts

Technicians trace the circuit from the switch to the ignition system and starter motor, ensuring every connection is sound.

Pinpointing the Stop Start Switch in a Schematic

Identifying the switch on the diagram is crucial. This element is typically marked by a simple “ON/OFF” symbol and is central to the entire system.

Utilizing a Diagram for Auto Start Stop System Checks

A control diagram is an indispensable tool during inspections. It offers a clear visual of wiring and components, enabling swift identification of malfunctions in the system.

How to Wire a Start Stop Switch on Your Small Engine

Wiring a start stop switch involves several safety measures. Always disconnect the battery before beginning any work on the electrical system. With the right tools and supplies—like wire strippers, soldering irons, and appropriate connectors—the process becomes straightforward.

Contact Langir for Custom Engine Stop Start Switch

Essential Safety Measures Before Wiring Work

Safety is paramount. Disconnect power sources, secure all cables, and wear protective gear to reduce the risk of shock or short circuits.

Necessary Tools and Supplies for Small Engine Switch Installation

The basic kit should include screwdrivers, pliers, electrical tape, and a multimeter to test voltage levels during installation.

Connecting a Standard Stop Start Switch Step by Step

- Disconnect the battery.

- Locate and remove the old switch if present.

- Connect the wiring harness to the new switch ensuring correct polarity. Each step requires careful verification to prevent miswiring.

Wiring Specifics for Auto Start Stop Configurations

When dealing with auto systems, ensure sensor wires are integrated. Such systems use additional connectors that require exact placement to communicate with the engine control unit.

Verifying Correct Stop Start Switch Setup

Once wired, test the circuit with a multimeter. This step confirms that the switch properly interrupts and restores power to engine components.

Common Faults With a Small Engine Stop Start Switch

Faults in the switch can lead to inconsistent engine performance. Common issues include loss of power, improper signal transmission, and physical wear signs. Troubleshooting involves checking the wiring diagram, testing the switch using a multimeter, and confirming that sensors are correctly aligned.

Contact Langir for Custom Engine Stop Start Switch

Indicators of a Malfunctioning Stop Start Switch

Signs include the engine not starting, unexpected shutdowns, or erratic behavior during normal operations.

Methods for Testing Switch Performance

Technicians often use digital multimeters and diagnostic tools. These methods verify if the switch is registering the correct voltage and if its response times are within acceptable ranges.

Resolving Problems in Auto Start Stop Mechanisms

Solutions range from repairing loose connections to completely replacing the switch if wear is extensive. Regular maintenance can prevent many common faults.

Deciding Between Repair or Replacement of a Small Engine Switch

A cost-benefit analysis can help here: minor faults may be repaired, whereas serious damage usually calls for a replacement to ensure reliability.

Selecting a Suitable Stop Start Switch for a Small Engine

Choosing the right push button switch depends on engine demands and usage conditions. There are various types available, each with unique advantages that can improve efficiency and durability. The decision may come down to whether the application requires a manual or automatic configuration.

Contact Langir for Custom Engine Stop Start Switch

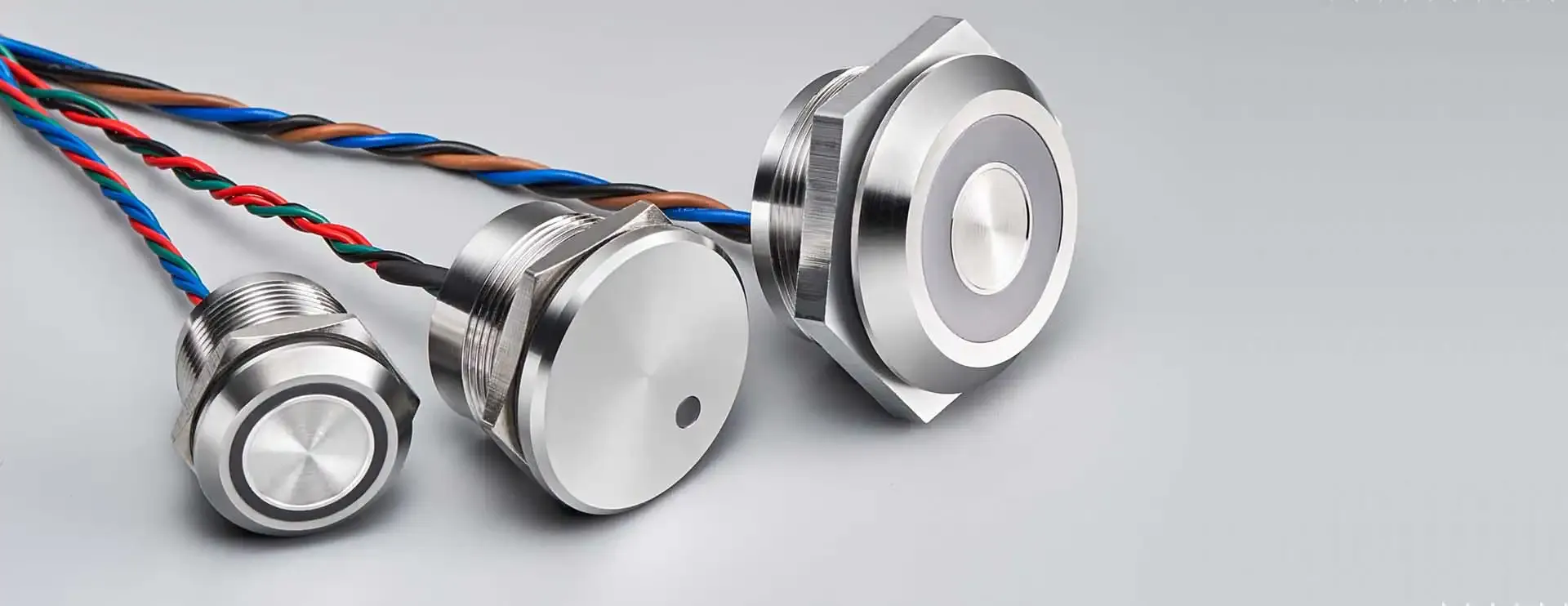

Available Varieties of Stop Start Switches for Small Engines

Consider options like mechanical, electronic, or hybrid switches. Each type offers unique durability and response characteristics suitable for different engines—from gasoline to diesel.

Aligning Switch Features With Small Engine Demands

Match the voltage, current rating, and operating temperature range to your engine’s specific needs. Properly rated components ensure long-term performance and safety.

Factors for Considering an Auto Start Stop System Upgrade

Upgrades may include advanced sensor integration and digital control, which can significantly enhance reliability and fuel efficiency.

Finding Reliable Suppliers for Small Engine Stop Start Switches

Working with trusted manufacturers—like Langir—ensures low MOQs, fast turnaround times, and high-quality products that meet industrial standards. Quality suppliers will offer comprehensive support for troubleshooting and repair.

How the Stop Start Switch Works on Small Engines | FAQs

How does a stop start switch affect engine performance?

It ensures that the engine stops and starts efficiently, reducing wear and enhancing fuel efficiency by controlling power interruption precisely.

Can I upgrade from a manual to an auto start stop system?

Yes, upgrading can improve performance by integrating sensors and digital controls, though it may require additional wiring and component compatibility checks.

What common issues arise with small engine stop start switches?

Common problems include wiring faults, sensor misalignments, and general wear, all of which can typically be troubleshooted with a multimeter and proper circuit diagrams.

EN

EN