Ever wonder why your push button starter switch sometimes fails to work? This guide shows how to test a push button starter switch quickly and effectively. It covers simple checks, common issues, and repair techniques you can use right away. The reader will learn practical steps to spot problems early and save time on costly fixes. Get ready to solve your starter switch issues with clear, hands-on advice.

Common Issues With Push Button Starter Switches

Loose wiring connections in the starter circuit, a damaged button mechanism, battery issues, a faulty starter relay, and ignition system condition all add up to potential trouble. Each factor plays a key role—whether it’s a bad electrical connector or unwanted noise from electricity transitions. Even hybrid systems can be thrown off track. This gives practical insight into common pain points.

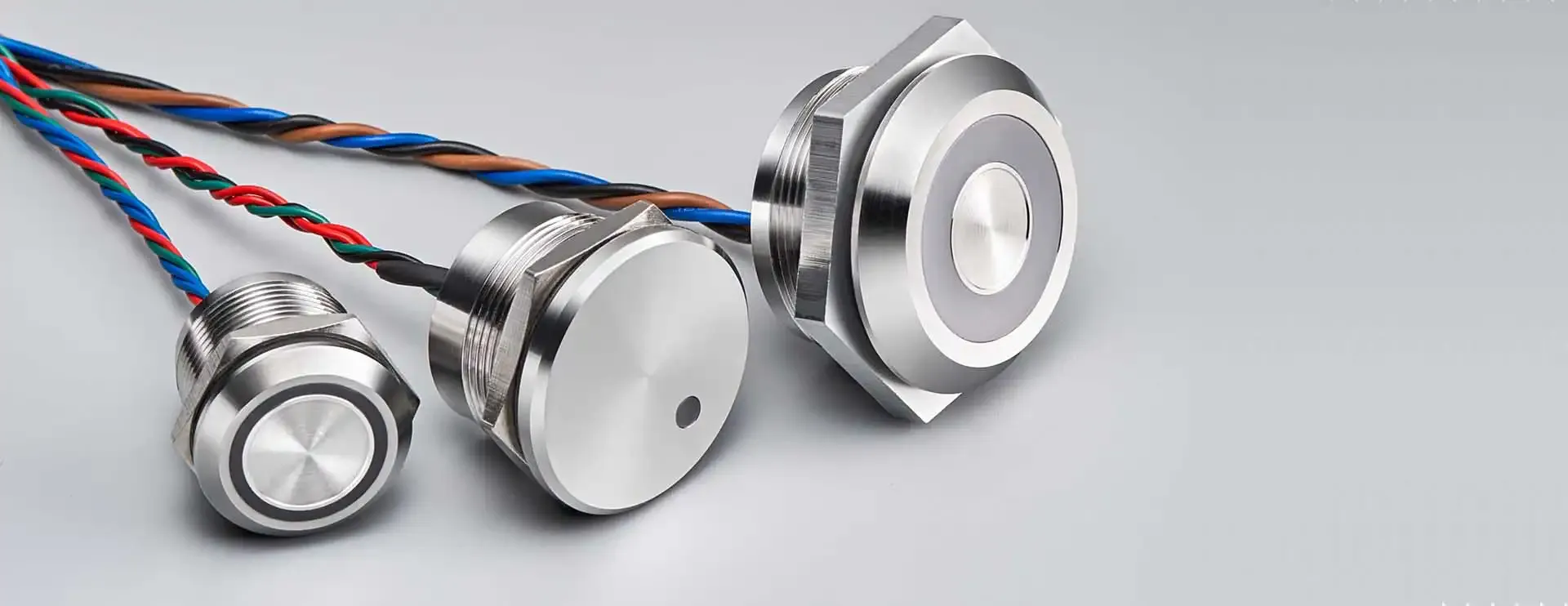

Contact Langir for Custom Push Button Starter Switches

Loose Wiring Connections in the Starter Circuit

Loose wiring can be a major offender when a push start car not starting happens, as a shaky connection can interfere with the starter solenoid and confuse ignition systems, sometimes even triggering a theft alert that leaves one needing a jump start:

The Push Button Mechanism for Damage

The push button mechanism can become a weak point if it gets hit wrong—maybe a jolt at the wheel or even around the steering wheel sends a shock through the system that makes it hard to crank the engine. Experts suggest that when odd behavior shows up, it’s smart to contact Langir for a check, especially if your cart setup feels off or misfires during use.

Battery Health and Voltage Levels

Battery health can make or break the push button starter switch test. Low voltage can mess up the whole gear of system checks and affect the transmission of power across circuits, a challenge not unknown in the automotive industry where even fuel delivery issues and concerns from a ford motor company perspective come into play:

- Examine voltage levels carefully

- Check for proper battery connections

- Assess if voltage influences component performance

The Starter Relay Isn’t Functioning Properly

The starter relay not functioning properly can throw a wrench in the whole push button starter setup, leaving users scratching their head and checking the box for spare parts. Experts recommend using a multimeter to test ignition switch with multimeter, ensuring every signal is on point, and even suggest trying a foot tap to see if a loose connection might be playing tricks. For hands-on fixes, it’s smart to share any odd behavior through your email address to reliable service providers that specialize in keyless entry systems.

The Condition of Your Ignition System

The state of the ignition system matters big time when testing a push button starter switch, as even a dodgy resistor or static radio interference can mess with your startup. Most experts say a quick inspection, backed by recent guidelines from the national highway traffic safety administration, ensures no hissing hint of carbon monoxide leaks signal any underlying issues.

Simple Checks to Diagnose Issues Efficiently

Test the push button starter switch quickly. Check it with a multimeter, clean corroded contacts, and use a jump start to bypass power issues. Keep an eye on any electrical shorts and inspect ground connections. Experts also suggest comparing spark plug performance and fuel injection signals. This advice could save a lot of roadside assistance needs and lead your troubleshooting right.

Contact Langir for Custom Push Button Starter Switches

Test the Push Button Switch With a Multimeter

A technician gives the push button switch a spin with a multimeter, ensuring that the push start system runs smooth and secure. He checks every connection so that the communication between components stays solid, protecting the warranty and keeping the power window in sync with the rest of the setup.

Clean Corroded Contacts on the Starter Switch

The technician wipes away corrosion from the starter switch contacts with a damp cloth, keeping the system running smooth like a well-tuned Ford Mustang. This simple step can also keep the alternator in check and enable a power delivery that even a luxury car might envy. The hands-on approach ensures the starter switch is pristine and reliable, cutting down chances of unexpected glitches.

Use a Jump Start to Bypass Power Issues

When a push button starter switch shows signs of power issues, using a jump start can clear out temporary glitches that affect the solenoid and brake signals, ensuring the technology and wiring are on track—much like double-checking the JavaScript in a web app or making sure a tire is properly inflated:

- Test connections with a multimeter

- Clean contacts to remove corrosion

- Confirm voltage levels are stable

Monitor for Electrical Shorts in the Wiring

When testing a push button starter switch, a technician keeps an eye out for electrical shorts in the wiring by checking each connection carefully, ensuring that the jun system and clutch components sync perfectly with the computer controls in the electronics setup, just like in a chevrolet silverado. The process includes a thorough visual inspection and a quick multimeter test to spot any irregular signals:

- Check wiring integrity and secure all connections

- Use a multimeter to confirm stable voltage readings

- Inspect key components for any signs of shorts

Examine the Ground Connections for Integrity

The technician checks the ground connections with a multimeter to avoid any loose links that can mess up the whole push button starter switch. This quick check is like keeping a secure pocket of well-organized articles that ensure every ship sets sail correctly, meeting the same standard as a well-calibrated air conditioning unit:

- Inspect all ground wires for secure fits

- Verify solid metal contacts with a multimeter test

- Ensure no corrosion holds back performance

Repair Techniques for Push Button Starter Failures

Replace damaged push button parts, secure loose wiring with proper connectors, apply electrical grease for corrosion resistance, and fix or replace the relay. This guide works for any suv, ford fusion, or car key system with a smart key, offering clear, practical repair steps that everyone can test and trust.

Contact Langir for Custom Push Button Starter Switches

Replace Damaged Push Button Components Easily

When push button systems start showing signs of wear, experts suggest replacing starter buttons and other damaged components promptly—this not only fixes the starter but also helps maintain the parking brake’s reliability and meets insurance standards for vehicle safety:

- Identify faulty starter components and confirm the issue with a multimeter.

- Remove damaged parts and secure tight wiring connections.

- Install new starter buttons and test the complete system.

Secure Loose Wiring With Proper Connectors

Loose wiring at the steering column can wreak havoc on a push button system, whether it’s in a Honda Accord or another model; using proper connectors not only secures these wires but also prevents issues with the ignition coil and other key parts. The technician advises that checking and tightening connectors early on can save time and effort while testing a push button starter switch:

- Inspect wiring near the steering column

- Secure connections with the right connectors

- Ensure compatibility with parts in a Honda Accord

- Test the ignition coil and overall push button system performance

Apply Electrical Grease for Corrosion Resistance

Experts recommend applying electrical grease to push button starter switches as a smart fix for corrosion issues; this step uses solid information to improve the ohm resistance in the wiring, ensuring smoother connections for the engine and even steady feedback from the steering and manual transmission systems. The move also prevents further damage that might disrupt key components, keeping the system reliable and efficient.

Fix or Replace the Starter Relay When Needed

When the push button starter switch acts up, a smart auto mechanic checks the fuse and inspects the starter relay for any signs of corrosion that might interrupt flow in the vehicle’s system. A prompt repair or replacement can get things humming again, saving time and avoiding bigger headaches down the road.

Reinstall and Test All Connections Thoroughly

The technician carefully reinstalls every connection, ensuring that no signal is lost along the way and that the ignition system runs smoothly, just like checking a keychain for its burst of energy before heading out in a Mazda. By methodically testing each link, this hands-on approach guarantees a robust repair that not only meets quality standards but could also bump up the sale price of the starter switch setup, making it a win for both safety and value.

Maintenance Tips for Long-Lasting Starter Performance

Regularly inspect wiring and connections, keep the push button switch free of carbon buildup and debris, and test battery voltage as seen in a ford explorer. Lubricate moving parts to avoid sticking and document any repairs for troubleshooting. These tips break the process into simple, practical steps for lasting starter performance.

Contact Langir for Custom Push Button Starter Switches

Regularly Inspect Wiring and Connections

Inspect wiring and connections on a regular basis and make sure the sensor readings match the expected values. A skilled technician finds that a quick visual check and test with a multimeter prevent most issues before they turn into major headaches. Keeping everything tight and clear saves both time and trouble down the road.

Keep the Push Button Mechanism Clean and Free of Debris

Langir experts say keeping the push button starter switch neat is key to long-lasting performance. A clean mechanism means fewer glitches and smoother starts, so technicians recommend these simple steps for staying on track:

- Wipe away dust and debris regularly

- Inspect contacts for any build-up

- Use the right cleaner on surfaces

Test Battery Voltage Periodically

The technician checks battery voltage every few months to keep the push starter switch on track. Regular measurements help spot voltage drops early and prevent unexpected starts from failing:

- Inspect battery connectors for tight fits

- Use a multimeter to verify the battery’s output

- Ensure stable voltage levels to support the starter switch

Lubricate Moving Parts to Prevent Sticking

They keep maintenance smooth by lubricating the moving parts on the push button starter switch to prevent sticking and keep everything running like a well-oiled machine. This hands-on fix ensures reliable performance and saves time troubleshooting, making it a no-brainer for anyone serious about starter upkeep.

Document Any Repairs or Replacements for Future Reference

Keeping detailed records of every push button starter switch repair or replacement helps technicians track issues over time and make more informed maintenance decisions. A log that outlines repair dates, parts replaced, and observed issues is a simple but effective tool for long-lasting performance:

Troubleshooting Advanced Circuit Issues With Proficiency

Consult wiring diagrams, check faulty components, and use diagnostic tools for smart problem-solving. Test for federal regulations compliance if necessary. When things get tricky, it’s best to call a pro. This section gives practical tips on detailed checks that keep your push button starter switch running smooth and efficient.

Contact Langir for Custom Push Button Starter Switches

Consult Wiring Diagrams for Complex Systems

The technician reviews wiring diagrams to pinpoint issues in the push button starter switch with no fuss, ensuring every connection fits its place. The practical insights gained from these diagrams help troubleshoot even complex systems, keeping repairs straightforward and dependable.

Check for Faulty Components in the Starter Circuit

When checking for faulty components in the starter circuit, the technician reviews every connection and component with a sharp eye on the push button starter switch’s performance, ensuring that nothing is out of whack. This detailed inspection spots any weak links and misbehaving parts that might kick off circuit issues, guiding the repair process with clear, practical steps:

Utilize Diagnostic Tools for Accurate Problem-Solving

Using a diagnostic tool gives engineers a clear, no-nonsense look at the electrical paths in a push button starter switch. With a few quick tests and focused measurements, a technician can pinpoint misfires or weak links that might leave a car stranded. It’s a smart, hands-on way to keep things running smoothly and maintain peak performance in starter circuits.

Test Federal Regulations Compliance if Applicable

When testing push button starter switch circuits, a technician checks that all parts meet federal guidelines. A multimeter and diagnostic tools make it easy to verify that every connection is in line with standard rules, ensuring smooth operation and avoiding future hassles:

Seek Assistance From Professional Technicians if Needed

When things get confusing with advanced circuit issues, calling in professional technicians is a wise move. Their hands-on expertise clears up any mix-ups in the push button starter switch system, helping the team avoid headaches and keep the process running smooth.

When to Replace Your Push Button Starter Switch

The expert looks for signs the switch is beyond repair, checks if fixing outweighs replacing, finds quality parts, maps out installation steps, and sticks to manufacturer tips. Each step helps ensure smart, cost-effective choices that keep the push button starter switch working reliably.

Contact Langir for Custom Push Button Starter Switches

Recognize Signs of Irreparable Damage

The technician notes that if a push button starter switch shows severe wear, chipped plastic, or stubborn electrical faults, it’s time to consider a replacement. Recognizing these signs early saves time and keeps the system safe, ensuring that customers avoid the hassle of unexpected failures on the road.

Evaluate Cost-Effectiveness of Repairs

The technician assesses repair costs against replacement expenses to decide if fixing a push button starter switch is a smart move. Tough calls like these come down to simple numbers:

Research Quality Replacement Options Available

Industry experts stress the importance of shopping for high-grade push button starter switches that match performance expectations and reliability standards. They urge readers to compare replacement options based on component quality, trustworthiness, and ease of installation:

Plan for Installation Steps Before Replacement

Before replacing a push button starter switch, the technician maps out each step to keep installation efficient and stress-free:

Follow Manufacturer Guidelines for Best Results

Manufacturers offer clear instructions that help technicians know when to let go of an old push button starter switch and install a fresh one. Following these guidelines means each connection and voltage test matches proven standards—keeping everyone on track and systems humming. Langir’s documented steps show that sticking to manufacturer advice can save time and sidestep future issues.

How to Test a Push Button Starter Switch | FAQs

What causes push button starter switch failures?

Push button starter switch failures often stem from worn contacts, dust build-up, and misalignment, all of which can lead to poor performance. Frequent use and exposure to humidity add to the mix.

How to check wiring on a starter switch?

Use a multimeter to measure voltage at each terminal. Check wiring against the standard diagram and inspect for loose or burnt spots. Always cut power and follow safety guidelines before testing the starter switch.

Which repairs fix common push button issues?

Common repairs include cleaning switch contacts, replacing worn-out buttons, and re-soldering loose joints. These fixes ensure smooth operation and durability for industrial push button switches.

What maintenance keeps starter switches reliable?

Starter switch upkeep involves regular cleaning, lubrication, and inspection to clear dust, check wiring, and replace worn parts. This routine care keeps switches dependable and ready to perform consistently in industrial settings.

When should a starter switch be replaced?

A starter switch should be replaced when it causes erratic engine behavior, unusual sounds, or a jammed start. These signs mean the switch no longer works right, and swapping it out can prevent bigger hassles down the road.

EN

EN