Struggling with a faulty industrial push button? This post breaks down key push button components and tackles common issues head-on. Readers get clear troubleshooting techniques and effective solutions to fix these problems fast, saving time and money. The tips shared here help prevent downtime and improve overall performance.

What are Industrial Push Button Components

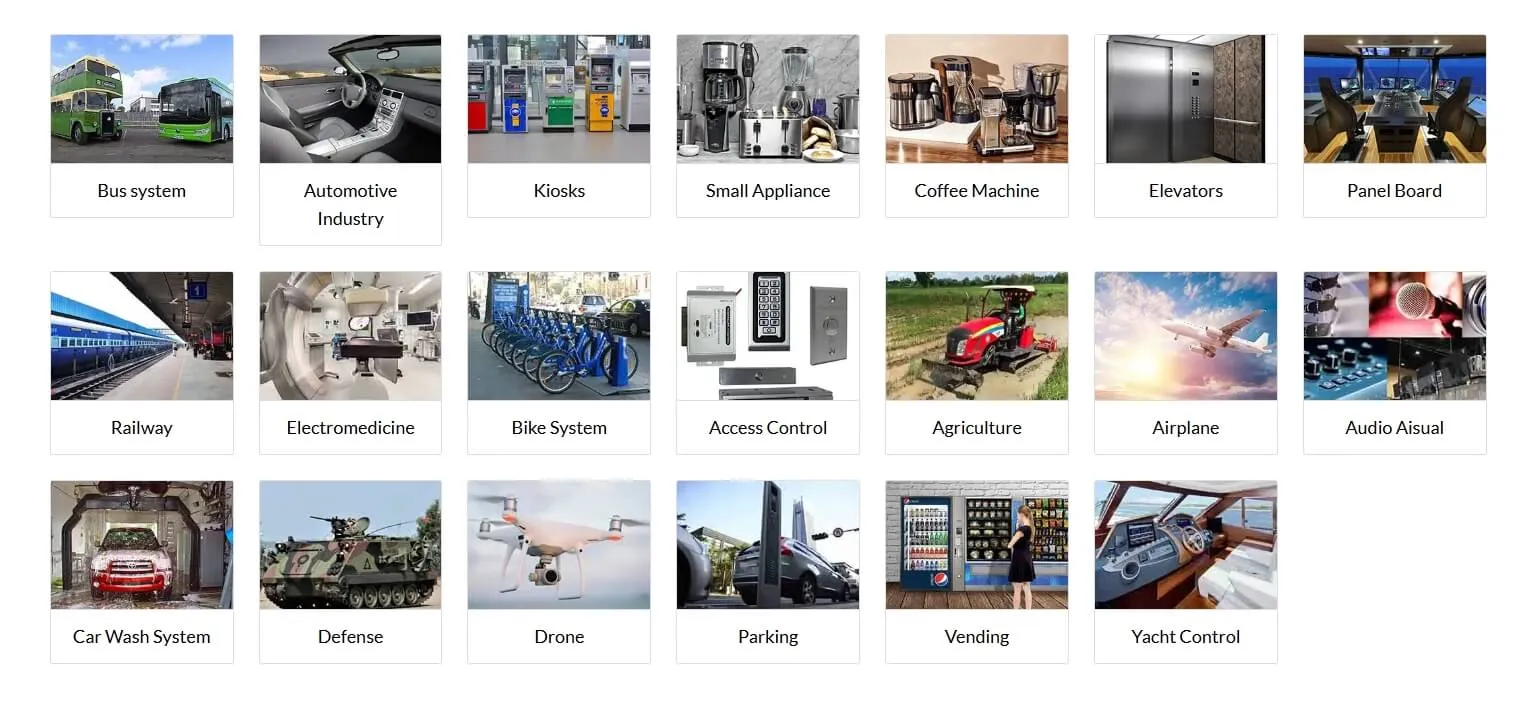

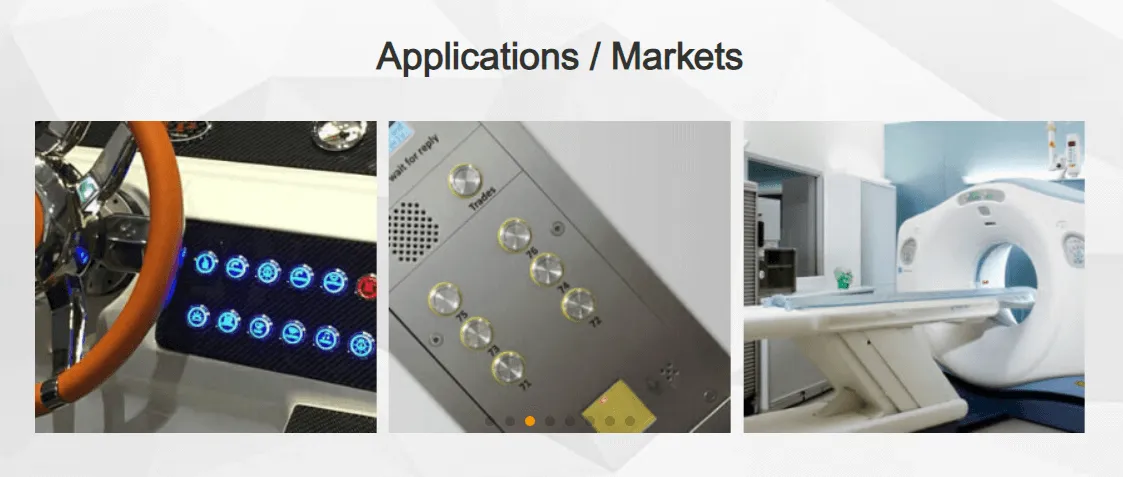

Industrial push buttons come in varied types, built tough with common materials and smart specs like ip code ratings and ergonomics. This gear impacts how equipment and machines perform. A quick web browser search shows experts that the right push button is key—setting the stage for clear insights into each component.

Overview of Push Button Types

Industrial push button types come in all shapes and sizes, from rugged steel models to sleek designs built for smooth management and integration with an operating system. These buttons often support transport layer security measures and prove useful in goodman furnace troubleshooting, making them a reliable choice when equipment demands practicality and ease.

Common Materials Used in Push Buttons

Industrial push buttons use tough metals, resilient plastics, and composite materials that keep a button push steady and reliable, even under harsh conditions. Experts in electrical buttons and switches know that quality materials help with equipment accounting and system software checks, avoiding confusing jargon by keeping it simple and smart:

- Stainless steel for durability

- Polycarbonate plastics for impact resistance

- Composite blends for optimized performance

Key Specifications and Features to Consider

Industrial push button specs boil down to a few real must-haves: solid design that can handle signals from a server, reliable wire connection to keep data flowing, and tough builds that work even when the situation feels as uncertain as a faulty doorbell or a skipped credit card swipe:

- Durable materials that stand up to heavy use

- Reliable design ensuring tight server integration

- Secure and proper wire connections for smooth function

- User-friendly performance that acts like a well-timed doorbell

- Cost-effective solutions with reliability like a credit card purchase

Importance of Selecting the Right Push Button

Choosing the right push button is vital for keeping an efficient system in place—one that integrates fault-free actuator controls supported by robust technology and helps build strong customer relationship management using a clear checklist:

Common Issues With Push Button Switches

Unresponsive push buttons have several culprits. Mechanical faults, environmental wear, and wiring mistakes mess up an http cache and impact the client experience. Next, the text looks at issues like lack of response, moving parts going off-track, harsh surroundings, and wiring errors—even those pesky malware hiccups. This sets the stage for smart fixes.

Unresponsive Push Buttons and Their Causes

Pushbuttons sometimes act up because the physical switch is worn out or loose wiring starts to misbehave. A smart process of elimination helps pinpoint if a transmission control protocol hiccup or even antivirus software is playing mind games, letting experts sort the issue and get things back on track.

Mechanical Issues Affecting Functionality

Engineers often face issues where mechanical parts just don’t work as planned. Wear on a pilot light or a loose wiring connection can disrupt frequency checks and wireless signals, forcing quick troubleshooting to get things back in line:

Environmental Factors and Durability Concerns

Industrial push button switches can struggle with wear from harsh weather and dusty factory floors, a hassle kind of like trying to fix ac in car issues on a scorching day. Research by comptia-trained pros shows that steady problem solving goes a long way in stopping packet loss and keeping these buttons tough and ready for action.

Wiring Errors Leading to Malfunction

Wiring errors in a push switch assembly can lead to misread signals and erratic pressure readings, even when the operating temperature is stable and the ip address is correctly set; a single loose connection may result in false alerts to the help desk:

- Loose wires affecting signal stability

- Misconnections causing erratic push switch behavior

- Improper cable routing impacting pressure transmission

- Faulty wiring leading to continuous help desk notifications

Troubleshooting Techniques for Push Button Switches

This section lays out a step-by-step process for troubleshooting industrial push buttons. It covers using multimeters to diagnose issues, checking loose wiring, and assessing control system fit—even for a momentary button on microsoft windows setups. A quick screenshot or resource guide adds practical insights to tackle common problems.

Step-by-Step Process for Effective Troubleshooting

The expert lays out a clear process for troubleshooting push button switches much like fixing goodman air conditioner problems—starting with a quick computer check alongside a robust firewall setup to catch any artificial intelligence glitches that might hint at a failure:

- Inspect each wiring connection for any looseness

- Use a computer diagnostic tool to check signal consistency

- Review settings on the firewall to ensure proper protection

- Check the physical button for signs of wear or damage

Using Multimeters to Diagnose Issues

Industrial push button experts use a multimeter as a no-nonsense tool to check every detail—from getting the definition of voltage levels on a latching switch right to keeping an eye on radio signals, all while verifying proper authentication and spotting any vulnerability in the setup:

- Measure voltage on latching switches

- Confirm stable authentication signals

- Inspect radio frequency output

- Identify any potential vulnerability

Identifying Loose Connections and Wiring Problems

Engineers see loose connections as a major hiccup in a button switch system that can throw off automation and ramp up downtime. The hypothesis here is simple—a tiny wiring slip or a misaligned default gateway can stop things cold, causing unexpected errors:

Assessing Compatibility With Control Systems

Assessing control system compatibility means checking if an electrical button plays nice with the rest of the system, all while keeping the complexity low. Experts often refer to a clear document and a table of contents in javascript guidelines to spot any misfits early on, saving time and effort.

Solutions for Common Push Button Problems

This section explains fixes for common industrial push button problems. It outlines routine care, component upgrades, protective measures against rough environments, and alternative designs to avoid failures. The tips compare a laptop’s adjustment of plastic parts to refining a gateway for smoother communication in any complex system.

Recommended Maintenance Practices

Industry experts note that routine maintenance in manufacturing is key, especially when a dpdt momentary switch starts acting up or a circuit breaker trips, dimming the light on efficiency; they recommend keeping an eye on every component via api checks and hands-on tests. Here are some essential steps to keep things running smoothly:

- Inspect the dpdt momentary switch regularly

- Test circuit breaker responsiveness during light checks

- Use api tools to monitor manufacturing performance

Upgrading Components for Enhanced Reliability

The manufacturer upgrades critical components to handle unpredictable behavior in systems, whether it’s a momentary contact switch or an e stop button acting up. They recommend a quick menu check on control panels and a fresh emergency stop button when the system shows signs of wear:

Implementing Protective Measures Against Environmental Damage

Industrial push button experts stress that protective measures against harsh weather and grime need to be spot on; they back up every move with careful root cause analysis, clear datasheet steps, and practical ge dishwasher troubleshooting to keep the starter button working like a champ:

Selecting Alternative Designs to Mitigate Failures

Industry experts say alternative designs can help when the usual fixes fall short. They often recommend debugging the controls like checking a clunky light switch, tracing the root of the issue before deciding to contact or reset the router. This straightforward approach cuts out the hassle and keeps systems running smoothly.

Best Practices for Maintenance of Industrial Push Buttons

Regular checks, smart cleaning, precise records, and hands-on training keep these buttons in top shape. This approach cuts latency, patches issues fast, and boosts team skill while giving customers clear information. It sets a strong base for solving common push button problems and helps keep systems running smoothly.

Regular Inspection Schedules

Regular inspection schedules act like keeping a tidy desk, ensuring every push button’s usability stays high and productivity doesn’t falter. Simple checks, inspired by tips from Schneider Electric and ideas found on the world wide web, let experts catch problems early and set systems right without fuss.

Cleaning Techniques for Longevity

Industrial push buttons need a good cleaning routine to keep them working right—sort of like when customer support steps in for an hp printer not printing, cutting through the nonsense and keeping things on track without letting dirt grow like a mushroom on old tech; experts point to basic upkeep as a beacon for reliable customer service. Follow these steps:

- Wipe away dust and grime with a damp cloth.

- Use a gentle detergent to lift stubborn particles.

- Dry off thoroughly to prevent moisture buildup.

- Inspect regularly to ensure ongoing performance.

Documentation of Maintenance Records

Documentation of maintenance records gives experts a clear trail to follow, much like tracking changes on a printed circuit board or catching a printer error over the internet. Detailed records of every check and Chamberlain garage door opener troubleshooting feedback help teams nail down push button issues quickly and keep operations running without a hitch.

Training Staff for Proper Usage

Industry experts note that training staff properly is a must in push button maintenance. They get hands-on with computer hardware checks, ensuring every power cord and signal passes the test, and boost their knowledge with clear analytics to keep systems humming along smoothly:

Resources for Further Assistance

This section offers hands-on tips. It covers contacting manufacturers for support, online forums for troubleshooting, and manuals plus compliance guidelines packed with knowledge management insights. Experts can use google chrome to search, rely on a trusty pin for minor fixes, and keep asset info front and center for easy troubleshooting.

Contacting Manufacturers for Support

When manufacturers offer support, they keep it simple for issues tied to electrical wiring and even challenges like samsung refrigerator problems. They assist customers facing hurdles with medical device controls or components like the eaton 10250t, ensuring a glove is always handy for on-site help:

- Reach out via phone or email for quick advice

- Review troubleshooting guides provided by support teams

- Get hands-on help with wiring adjustments and component checks

- Request personalized service for unique challenges

- Follow up with expert recommendations for preventive care

Online Forums and Communities for Troubleshooting Help

Industry experts find that online forums and communities offer a straightforward introduction to troubleshooting, mixing hands-on sensor techniques with practical advice on how every network packet can reveal hidden issues in metal or stainless steel components. This approachable community spirit helps ease pain points while giving professionals a real-world pulse on keeping push button systems running smoothly.

Manuals and Technical Documentation

Manuals and technical documentation serve as a steady online resource for anyone working with industrial pushbutton switches, offering clear steps to fix issues with a momentary switch in real-world scenarios. This reliable material provides practical learning that cuts through the confusion and guides teams to quickly tackle emergency repairs.

Industry Standards and Compliance Guidelines

Industry standards and compliance guidelines set a solid blueprint for smooth industrial push button operations, acting as a clear interface between design and real-world application—much like avoiding a glitch on a smartphone or the headache of an ice maker not making ice. Data-backed practices help manufacturers fine-tune every detail, so issues are caught early and systems work as they should.

How to Troubleshoot Common Issues with Industrial Push Buttons | FAQs

What are the main parts of an industrial push button?

Industrial push buttons mainly consist of an actuator, a housing, a contact mechanism, and a terminal assembly. Each part works together to offer safe, reliable switching in tough industrial settings.

Which issues are common with push button switches?

Push button switches often face issues like worn contacts, misalignment, and debris buildup, which may cause erratic performance. Regular inspections and proper cleaning can keep them reliable for everyday industrial work.

How can faulty push buttons be troubleshot?

Start by checking wiring and cleaning contacts. Test the button with a multimeter and inspect solder joints for cracks. Replace any faulty parts to keep your push button switches running smoothly.

What solutions fix frequent push button problems?

Fixing frequent push button issues means checking loose contacts, re-calibrating the switch mechanism, and sometimes swapping in reliable, bulk-customized units. Regular maintenance cuts down on misfires and boosts performance.

Where can further resources on push button maintenance be found?

Check out trusted industry websites, our resource center, and top contractor forums for clear guides on push button maintenance. These platforms offer practical tips and expert advice to keep your push button switches running smoothly.

EN

EN