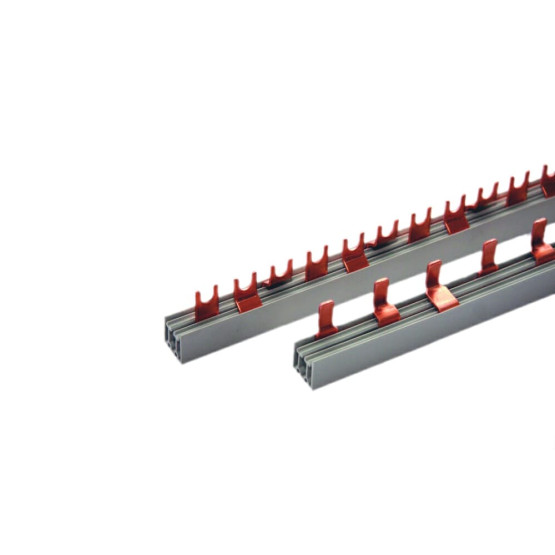

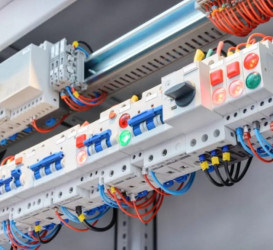

The Busbar System is an innovative way to jumper up to 57 poles of Manual Motor Controllers (MMC) and Supplementary Protectors (SP).

Electrical Busbar System

The Electrical Busbar System is an innovative way to jumper up to 57 poles of Manual Motor Controllers (MMC) and Supplementary Protectors (SP).

Electrical Busbar System

The advantages of this busbar system are:

- 30% Installation time savings

- Panel space savings

- Reduced maintenance

- High electrical ratings

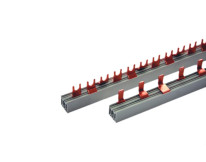

Electrical Busbar System 1P+N

- Shape: Pin Type

- Rated current: 32A

- Rated insulating voltage: 500V AC

- Flammability of plastic part: class 1

| Items | Rating (Amps) | Terminals | Pack Qty. | Length | Cat. No. |

| 1P+N | 32A | 56 | 100 | 1m | BB101N |

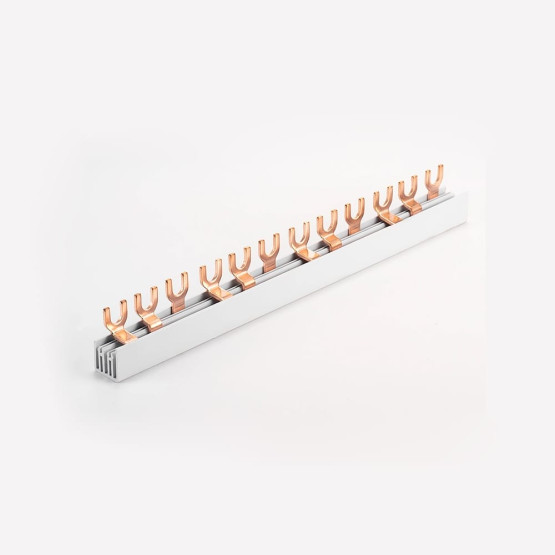

Busbar 1P, 2P, 3P, 4P

- Shape: Pin type, Fork Type

- Rated Current: 63,125A

- Rated Insulating Voltage: 500VAC

- Flammbaility of Plastic Part: Class 1

| Items | No. of pole | Current Rating (Amps) | Terminals | Cat. No. |

| (PIN) Type | 1 | 63A | 56(55) | BB101 |

| 100A | 56(55) | BB101A | ||

| 2 | 63A | 27 | BB201 | |

| 100A | 27 | BB201A | ||

| 3 | 63A | 18 | BB301 | |

| 100A | 18 | BB301A | ||

| 4 | 63A | 14 | BB401 | |

| 100A | 14 | BB401A |

| Items | No. of pole | Current Rating (Amps) | Terminals | Cat. No. |

| Fork Type | 1 | 63A | 56(55) | BB102 |

| 100A | 56(55) | BB102A | ||

| 2 | 63A | 27 | BB202 | |

| 100A | 27 | BB202A | ||

| 3 | 63A | 18 | BB302 | |

| 100A | 18 | BB302A | ||

| 4 | 63A | 14 | BB402 | |

| 100A | 14 | BB402A |

Accessory

End Cap

- Adaptable to full range busbars

- Used to insulate the exposed living parts at both ends of busbar

Terminal Adaptor

- Application to busbar for terminal connection

- Fixed on busbar insulating part to secure high reliability

- Connection capacity: 25mm2

Power Feed Lug

SK-805

SK-805P

SK-806

SK-806P

SK-905

Insulation Cap

SKU

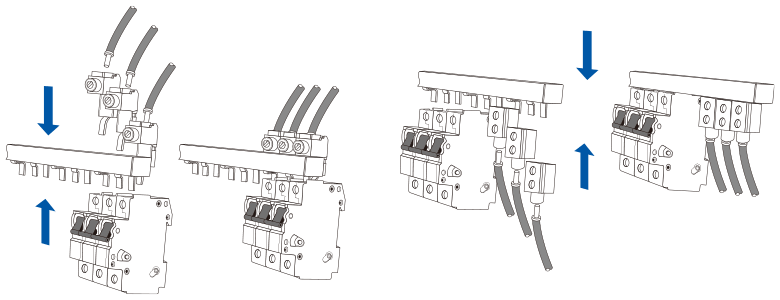

Assembly Instructions

FAQs

1. What is an electrical busbar system?

An electrical busbar system is a network of conductors used to distribute and transmit electrical power within a building or industrial facility. It consists of insulated bars or strips that provide a reliable and efficient method of power distribution.

2. What are the advantages of using an electrical busbar system?

Reduced installation time, improved flexibility, higher power density, enhanced electrical safety, and easier maintenance compared to traditional cable-based systems.

3. How is an electrical busbar system different from conventional cabling?

Unlike conventional cabling, an electrical busbar system uses a compact and modular design, eliminating the need for multiple individual cables. This results in reduced installation complexity, improved space utilization, and enhanced electrical efficiency.

4. How is the capacity of an electrical busbar system determined?

It’s determined by factors such as the cross-sectional area of the busbars, the material used, the temperature rating, and the design considerations for current-carrying capacity and voltage drop.

5. What is the maintenance required for an electrical busbar system?

It generally requires minimal maintenance. Routine inspections, cleaning, and periodic tightening of connections are recommended to ensure optimal performance and longevity.

6. Are there safety considerations when using a busbar system?

Yes, safety is an important aspect. Proper grounding, insulation, and protection against short-circuits and overloads are essential to ensure safe and reliable operation.

7. What is the purpose of an electrical busbar system in power distribution?

It serves as a centralized conductor for efficiently distributing electrical power from the source to various loads within a facility or system.

8. What are the main components of an electrical busbar system?

The busbar system includes busbars (conductive bars or strips), supports, insulators, connectors, expansion joints, and protective covers.

9. What are the different types of busbar configurations commonly used?

Common busbar configurations include single busbar, double busbar, ring busbar, and sandwich busbar arrangements. Each configuration offers specific advantages depending on the application requirements.

10. What are the considerations for selecting the appropriate busbar material?

It depends on factors such as electrical conductivity, thermal properties, mechanical strength, corrosion resistance, cost, and specific application requirements.

11. How is fault protection and coordination achieved in an electrical busbar system?

Fault protection and coordination are achieved through the use of protective devices such as circuit breakers, fuses, relays, and current-limiting devices. Proper coordination ensures selective and timely fault isolation.

12. What are the safety measures to be followed during the installation and maintenance of a busbar system?

Safety measures include proper personal protective equipment (PPE), adherence to electrical safety standards, grounding and bonding practices, lockout/tagout procedures, and regular inspection and maintenance schedules.

13. Can an electrical busbar system be used in outdoor or harsh environments?

Yes, they can be designed for outdoor or harsh environments by incorporating features such as weather-resistant enclosures, corrosion-resistant coatings, and appropriate insulation systems.

Main products

Electrical Busbar System

35mm DIN Rail

DC Circuit Breaker – Miniature Circuit Breakers for DC and Solar Generation

IEC 60947-2, EN60947-2, GB 14048.2

English

English 简体中文

简体中文